Grades Of Stainless Steel

Grades Of Stainless Steel Related Searches

Shiny Or Dull Side Of Aluminum Foil For Cooking Inverter For 100w Solar Panel Solar Panel Inverter For Rv Pvc Tiles For Walls Wall Lights For Bedrooms Inverter Ac With Solar Panel Solar Panel With Inverter Kit Solar Panel Kits With Inverter Solar Panel With Inverter Direct Roving For PultrusionHot Searches

Steel Mesh Panels For Sale Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Aluminum Bar Stock For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Cost Of Awnings For Decks Type Of Scaffolding With Pdf Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel Galvanized Steel Scrap Price Type Of Stainless Steel Types Of Stainless Steel Grades Types Of Stainless Steel Aluminum Corp Of China Stock Types Of Scaffolding In Construction Pdf Stainless Steel Factory Stainless Steel TypeGrades Of Stainless Steel Supplier & Manufacturer from China

Okorder.com is a professional Grades Of Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Grades Of Stainless Steel firm in China.Hot Products

FAQ

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- The main difference between stainless steel sheets and regular steel sheets is that stainless steel is an alloy that contains a minimum of 10.5% chromium, which gives it its unique corrosion-resistant properties. Regular steel, on the other hand, does not contain enough chromium to be considered stainless and is more prone to rust and corrosion. Stainless steel sheets are also typically more expensive than regular steel sheets due to their enhanced durability and resistance to corrosion.

- Yes, stainless steel sheets can be used for decorative signage. Stainless steel is a versatile material that offers a sleek and modern aesthetic, making it a popular choice for various applications, including signage. Its durability and resistance to corrosion make it suitable for both indoor and outdoor use. Stainless steel sheets can be laser-cut, engraved, or etched to create intricate designs, logos, or lettering, allowing for endless possibilities in creating decorative signage. Whether it's for commercial, residential, or public spaces, stainless steel sheets can provide a sophisticated and long-lasting solution for decorative signage.

- What is stainless steel AB board, please?

- The 2B board is basically a matt surface, according to a BA object, in approximate mirror, can more clearly illuminate the object (a little paste).

- There are several different types of stainless steel sheet surface coatings that are commonly used for outdoor applications. These coatings are designed to enhance the durability and corrosion resistance of the stainless steel, making it suitable for use in harsh outdoor environments. One of the most common coatings used for outdoor applications is a powder coating. Powder coating is a process in which a dry powder is applied to the stainless steel surface and then cured under heat to form a protective layer. This coating provides excellent resistance to corrosion, UV rays, and chemicals, making it ideal for outdoor use. It also offers a wide range of color options, allowing for customization and aesthetic appeal. Another type of coating commonly used for outdoor applications is a PVD (Physical Vapor Deposition) coating. This process involves the deposition of a thin film of material onto the stainless steel surface through a vacuum chamber. PVD coatings provide excellent adhesion, wear resistance, and corrosion resistance, making them suitable for outdoor applications. They also offer a variety of decorative finishes, such as gold, bronze, or black, which can enhance the appearance of the stainless steel. Additionally, stainless steel can be coated with a ceramic coating for outdoor use. Ceramic coatings are typically applied through a high-temperature spray process, which forms a hard, protective layer on the stainless steel surface. These coatings offer superior resistance to abrasion, chemicals, and UV rays, making them ideal for outdoor applications that require high durability. In summary, the different types of stainless steel sheet surface coatings for outdoor applications include powder coating, PVD coatings, and ceramic coatings. Each of these coatings provides unique benefits in terms of corrosion resistance, durability, and aesthetic appeal, allowing for the use of stainless steel in a wide range of outdoor environments.

- To prevent intergranular corrosion on stainless steel sheets, there are several steps that can be taken: 1. Opt for the appropriate stainless steel grade: Choose stainless steel grades that are specifically designed to resist intergranular corrosion, such as 304L, 316L, or 321. These grades have a lower carbon content, which minimizes the formation of chromium carbides at grain boundaries. 2. Apply heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This treatment eliminates any chromium carbides that may have formed during welding or high-temperature processing, effectively preventing intergranular corrosion. 3. Avoid high temperature exposure: It is crucial to avoid subjecting stainless steel sheets to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. Prolonged exposure to such temperatures can lead to the formation of chromium carbides at the grain boundaries, rendering the stainless steel susceptible to intergranular corrosion. 4. Utilize proper welding techniques: When welding stainless steel sheets, it is important to employ low heat input and minimize the duration of exposure to high temperatures. These measures help reduce the formation of chromium carbides and preserve the corrosion resistance of the stainless steel. 5. Employ pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets undergo thorough pickling and passivation. Pickling removes any surface contaminants, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regularly maintain and clean: To prevent potential corrosion, it is essential to keep the stainless steel sheets clean and free from contaminants. Regularly clean the surfaces using mild detergents and avoid the use of harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, the risk of intergranular corrosion on stainless steel sheets can be significantly reduced, allowing for the preservation of their corrosion resistance properties and an extended lifespan.

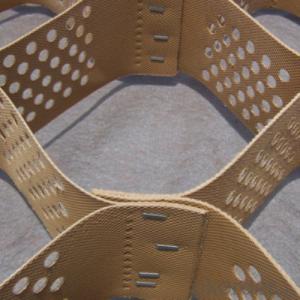

- When it comes to acoustics, there are several advantages to using perforated stainless steel sheets. Firstly, they have excellent sound absorption properties. The evenly distributed perforations in the sheets help to scatter sound waves, reducing their energy and preventing them from bouncing back into the room. This reduces echo and reverberation, creating a more comfortable and clear acoustic environment. In addition, these sheets can be customized to meet specific acoustic requirements. The size, shape, and pattern of the perforations can be adjusted to achieve different levels of sound absorption. This allows for precise control over the acoustics of a space, making it suitable for various applications such as concert halls, recording studios, theaters, or office spaces. Moreover, perforated stainless steel sheets are highly durable and long-lasting. They are resistant to corrosion, making them capable of withstanding harsh environments without deteriorating over time. This makes them suitable for both indoor and outdoor use, ensuring consistent acoustic performance for many years. Furthermore, these sheets offer an aesthetic appeal. The perforations can be designed in different patterns and sizes, providing a visually pleasing and modern look. This makes them a popular choice for architectural and design applications, where both acoustics and aesthetics are important. In conclusion, perforated stainless steel sheets offer excellent sound absorption, customization options, durability, and an attractive appearance. These qualities make them a versatile and effective solution for improving the acoustic performance of various spaces.

- Yes, stainless steel sheets can be bent or formed into different shapes. Stainless steel is a highly versatile material that can be manipulated through various processes such as bending, rolling, and forming to create a wide range of shapes and structures. The ability to bend stainless steel sheets makes it suitable for applications in industries such as architecture, automotive, and manufacturing. Additionally, stainless steel's corrosion resistance properties are not compromised during the bending process, making it a durable and long-lasting material choice for various purposes.