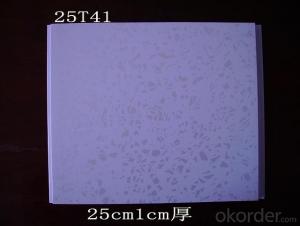

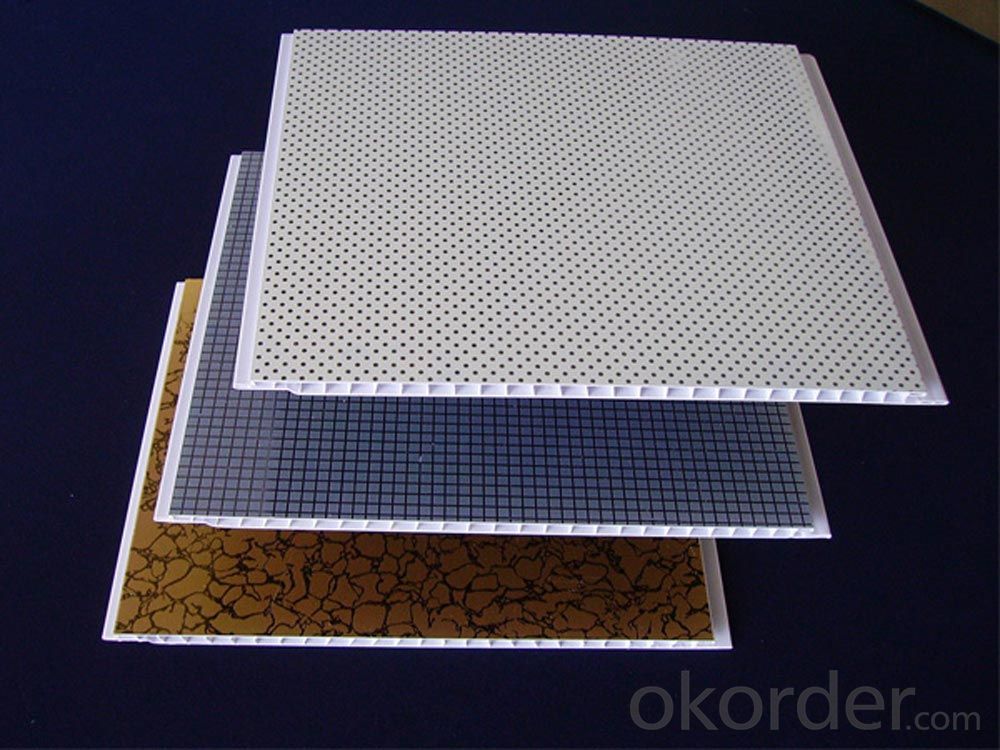

PVC Ceiling of Morden Design Plastic Priting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

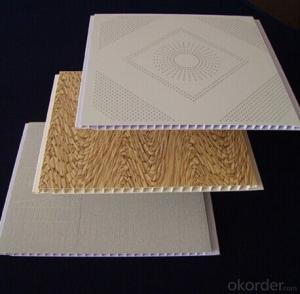

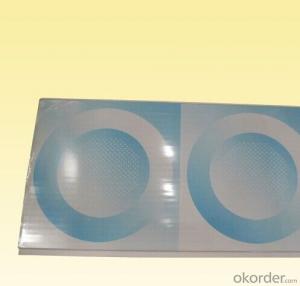

PVC ceilings are the ideal way to deliver tempered air from preheated hallways to farrowing or nursery rooms. The hollow profile acts as an air plenum delivering the air through precisely sized and positioned holes. The air enters the room uniformly without creating drafts.

Product Applications:

PVC ceiling panels solves the problem of dirty, unhygienic ceilings that are difficult, and expensive to clean by providing a bright, durable and hygienic surface, which is easily maintained. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

Product Advantages:

High intensity/Bendable/Resist erosion/Fire-proof aging-resisting/Durable

.

Main Product Features:

1.Design Type:Flat glossy and clear

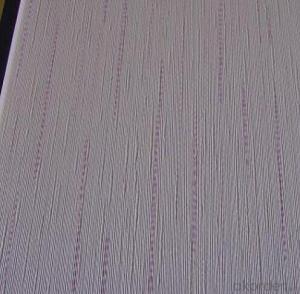

2.So many patterns can meet your needs

3.Environmental protection

4.The product never fade easily

5.Easy to clean and install

6.High quality,good service and good price

7.For indoor decoration, e.g.ceiling and wall decoration

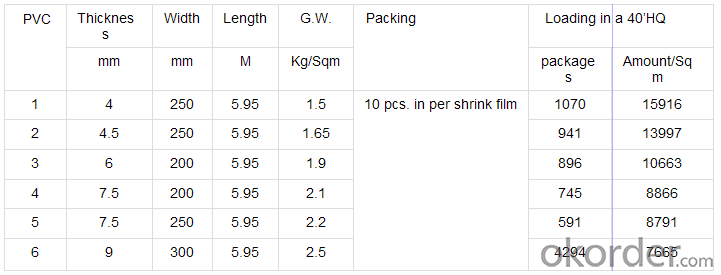

Product Specifications:

FAQ:

1.Terms of payment:

30%T/T deposit, 70% before the shipment.

2.Delivery time:

within 7-10 days after receiving the 30% deposit.

3. Port of Loading:Shanghai

4.Price terms: FOB Shanghai

Images:

- Q:Uv printer hit pvc board why a scraping off Before the scraping is very good scraping off, and now a nail plan, plans to fall out

- I have found this problem. It is estimated that you buy is to strengthen the hardened PVC board, the recent market there have been. This PVC board surface is very hard, pinch and draw with nails can not get printed, resulting in UV ink with the combination is not very good. Before the market flow of PVC foam board surface density is relatively small, playing to the firmness is very good. The solution to this problem is very simple to treat him as a print glass, before wiping the glass coating before printing, the firmness is quite good. Of course, if you use UV printer to print ordinary PVC foam board, you can not do any pre-treatment.

- Q:What is the difference between aluminum buckle and PVC gusset?

- Life and hiding capacity, more superior to PVC material. 1. Light weight, heat insulation, moisture, moisture, flame retardant, Naisuan Jian, anti-corrosion. Stability, good dielectric, durable, anti-aging, easy welding and bonding. 2. Flexural strength and impact toughness, high elongation at break, through the kneading, mixing, pull sheeting, pelletizing, extrusion or die casting process can easily be processed to meet the needs of various profiles. 2. Smooth surface, bright color, very decorative, decorative applications wider. Aluminum slab: a kind of new home furnishings in the 1990s, mainly used for kitchen and toilet ceiling works. As the entire process of aluminum slabs to use all-metal to create, in the service life and the ability to surround, more superior to PVC materials and steel materials, at present, the aluminum plate has become a home improvement throughout the project one of the indispensable materials. People tend to aluminum plate as metaphor: 'kitchen and toilet' is because he is the kitchen and bathroom with better protection and beautification of the decorative effect! At present, the aluminum slab plate industry has been in the country, large and medium-sized cities in full popularity, and has matured, comprehensive.

- Q:Curve saw can not saw 15mm pvc board? Will it be melted?

- Gray handle Curved saw blade is particularly suitable for cork, three plywood and fiberboard cutting, can also be applied to hardwood and plywood.

- Q:How many years can I use a PVC

- Standard design PVC gusset life should be around 15 years ? Cut the fun of the conscience of the boss produced about 3 years of scrap products

- Q:If you use PVC board to be a simple cylinder, then there is a piece of mouth that piece, how can we avoid it?

- With the injection molding process! It will not happen

- Q:I am going to be sealing the wall when making the basement a family room. Between the sump pump shooting out and the water traveling through the pipe, it's noisy. Anything that will quiet this?

- You will never get rid of all the sound, but you might dampen it a bit by insulating around the pipes. You can use fiberglass insulation (batts) and stuff it around the pipe before you close them up. If you insulate the entire ceiling it will also keep the family room noise from disturbing people upstairs from noisy people down stairs. (I almost said from teenagers, but that might not be politically correct LOL).

- Q:, Pvc board, wood keel ceiling, contractors, not packing materials, buy their own wooden screws, mainly to do the bathroom, toilet kitchen, open at 4 meters above, how much money a square meter can do

- PVC board a square meter dozens to hundreds of fast money.

- Q:How to buy pvc floor?

- Choose PVC floor method steps: 1, the first is to smell, with the nose sniff about whether the smell of the floor, the quality of qualified PVC floor is no smell. And those low quality floors contain formaldehyde. 2, you can use dirty soles in the floor surface scribble, the floor left behind the dirty traces, scrub with a clean cloth, if you can not clean or clean is not complete, indicating poor stain resistance of the floor. 3, you can use your fingertips, knives or some other sharp objects in the floor surface to pull the floor to test the wear resistance of the floor, the line marks are not obvious that the floor wear resistance is poor. 4, you can use the knife to cut the floor to test the stability of the floor, if the floor is easy to be cut, it shows that the floor is not glass fiber layer, so poor stability of the floor. 5, the test floor of the acid and alkali resistance, you can drop on the floor surface of alcohol, oil, a small amount of hydrochloric acid, one day after the observation of the surface of the floor there is a clear phenomenon of aging, and some on the floor that poor acid and alkali resistance. 6, test the antibacterial properties of PVC floor, will be easy to mildew items, such as bread and the like, on the floor surface, and the floor placed in the shade of the place, about two days after the observation of whether the surface of the fungus signs of growth, , Indicating that the floor is not antibacterial or antibacterial is very poor.

- Q:Pvc material plate how to weld?

- 1 engineering glue, 2 with a fuser

- Q:Pvc board can not be posted on the wallpaper, can be used to how long

- Yes, but this material should only use self-adhesive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling of Morden Design Plastic Priting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords