Superior Choosing wearing resistance material-Jaw Crusher

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

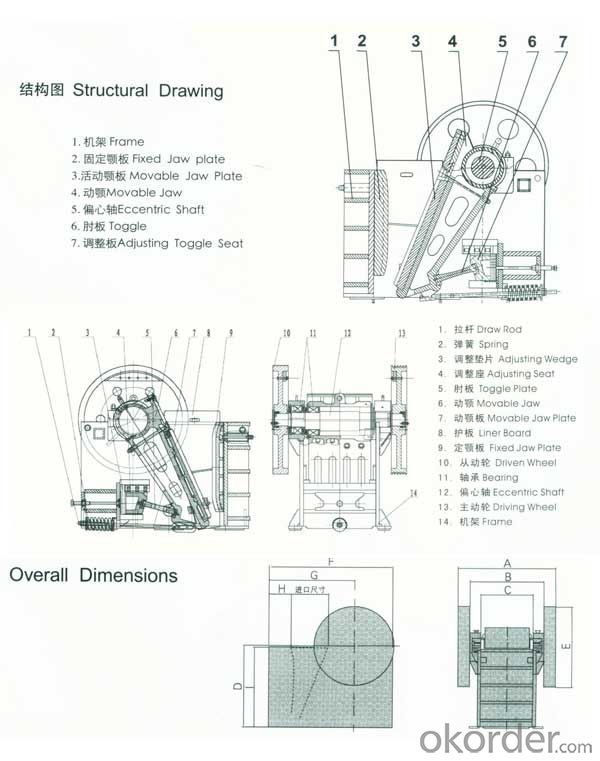

Jaw Crusher Introduction :

Jaw Crusher

Type: Primary Crusher

Input Size: 210mm--1020mm

Processed Materials: Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore, Manganese Ore, etc.

Applications: Aggregates Shaping, Mechanism sand, Bituminous Concrete, Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy

Capacity : 3-500 (t/h)

Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, larger capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

Features of jaw crusher :

1,High crushing ratio, well-distributed final product size.

2,Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it is capable to meet various requirements of customers

3,lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance

4,simple structure, reliable performance, low maintenance cost

5,little dust and low noise

Parameter of Jaw Crusher

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (m3/h) | Motor power(kw) | Weight (t) |

| PE-250*400 | 250*400 | 210 | 20-60 | 3-13 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 10-35 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 25-60 | 55 | 10.6 |

| PE-600*900 | 600*900 | 500 | 65-180 | 30-85 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 72-150 | 90-110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 85-143 | 90-110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 145-235 | 90-110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 170-250 | 90-110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 100-240 | 110-132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 190-275 | 110-132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 250-500 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 8-22 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 10-32 | 30-37 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 10-65 | 75 | 11 |

Reference Photos of jaw Crusher

- Q:katherometer is used as detector in Gas chromatography.Why.?

- This is the hardest part. Sadly, you'll never really know if he did it or not, he has lied to you a lotso it's almost impossible to believe. What you can do is go to a counselor, so you can get through this stuff, and then decide if this is worth it or not. I think your hunch is right, he had to have cheated with the things he has said to you, even my fiance agrees. No man who is in love with his wife will cheat, regardless if he has the chance or not. You seem very loyal and smart, you deserve so much better. Stay away from people's opinions during this time until you can figure out what you want/need to do. If your hubby has a reality check, like a serious one to see what life will be like for months without you or even talking with you, it may be of help. I do recommend you taking the time to figure out what to do. Good luck and I wish you the best.

- Q:has anyone ever heard of a wrestler called Da Crusher?

- Yes. His real names was Reginald Lisowski.

- Q:My smoke detectors keeping beeping as if it has low battery, and when I replace the smoke detectors; two months later the new smoke detectors that I just bought beeps again non-stop. Is it a wiring problem? Please help!!! :) TY

- Wow, that would be a violent demise. If your villain perhaps deserves a more serene death, he could be overcome by carbon dioxide while punching down the cap of grape skins at the top of a fermentation tank. Did he survive? Was he rescued from the tank? Wait for the sequel

- Q:what is the serial Lock Folder 5.0?

- Yes cos i would rather get drowned than burnt as you would look deformed and even if you get caught in the fire..hey theres water!

- Q:I know it was near the end of season 3 but in hat episode?Please help

- Last few minutes of 3x24 A Menage A Troi.

- Q:i have dumbells and a pulley (to do the pulldown)i do not find various workouts effective, i dont feel my triceps targeted

- Do some skullcrushers! :D Awesome triceps workout with a cool name

- Q:Pick one out of the following? Which is your favorite and why? A) Maybelline One by OneB) Covergirl Clump CrusherC) Covergirl Lash Perfection

- Any of the Covergirl Lashblast kinds. I prefer the Purple one (Waterproof version).

- Q:Where are the crushers located?

- It is used in mines, cement, coal, metallurgy, building materials, highways and combustion departments

- Q:i wear glasses and take chemistry. i often have to wear safety goggles in class, but when i wear them over my glasses, they feel so uncomfortable (not to mention they look ridiculous). i'm not so sure i want contacts because of the risk of infection and costs. what should i do?

- pH: ((from potential of Hydrogen) the logarithm of the reciprocal of hydrogen-ion concentration in gram atoms per liter; provides a measure on a scale from 0 to 14 of the acidity or alkalinity of a solution (where 7 is neutral and greater than 7 is more basic and less than 7 is more acidic). The formula for pH is simply: pH - log (H+ ions) Balance the equation - of putting Ba(OH)2 into H2O - and reverse the logarithmic function to determine how much ionic hydrogen is required. That will tell you how much of the Barium Hydroxide compound is required and hence the mass necessary to achieve the result.

- Q:Or would he turn to Riker for comfort?

- He's too busy partying at Starfleet Academy to care...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Superior Choosing wearing resistance material-Jaw Crusher

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords