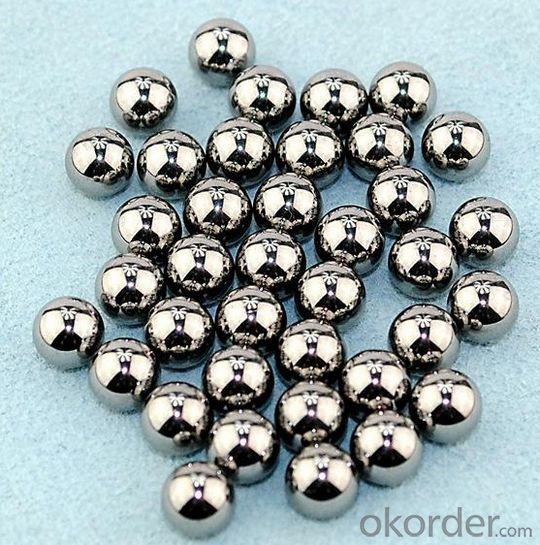

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

G100 6mm SS304 stainless steel ball for bearings(SGS approved) )

304 Stainless Steel Balls

Applied Area304 stainless steel ball can be used in iatrical instrument, chemical industry, aviation. Plastic hardware: scent bottle, sprayer, valve, nail polish, switch, washing machine, fridge, air condition, medicinal materials, automotive fittings, bearing, nursing

bottle and so on.

Speciality representative of Austenitic stainless steel. it is nonmagnetic, but magnetic after rolling, and the magnetism can be taken out, HRC≤26.It has good antirust and anticorrosive capability.

316 Stainless Steel Balls

Applied Are316 stainless steel ball is used in many special industry as iatrical instrument, chemical industry, aviation, scent bottle, sprayer, valve, nail polish, mobile phone fittings.

Speciality Austenitic stainless steels, It is the best steel ball in the steel ball area,HRC≤26,its Capability is better than 304 stainless steel ball.

420 Stainless Steel Balls

Applied Area420 stainless steel ball is used in the industry of high precision and antirust: motorcycle fittings, chain wheel,

stainless steel bearings, plastic bearings, craftwork, valve, petroleum and so on.

Speciality It is also called stainless iron, it is magnetic and has good antirust capability. The HRC is 50-55

Product Name | stainless steel ball |

Service | Your inquiry will be replied within 12 hours. |

Brand | HT |

Material | AISI 304, AISI 316, AISI 316L, AISI 420, AISI440, AISI440C and etc. |

Size | 0.7mm-25.4mm |

Feature | High polished, high precision, easy storage. |

Antirust Way | Provide dry packaging & slushing oil packaging. |

Grade | G10-G1000 |

Hardness | HRC 58-62 (If you have special requirements, please tell us.) |

Sample | Free |

Stock | There are emergency stocks for regular sizes. |

Packing Method | Standard Seaworthy Export Packing or Customized Packing |

- Q:What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q:What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q:My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q:What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q:What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q:The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q:What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q:What is the reason for 304 stainless steel precision casting parts to be changed?

- Mainly because of the cooling shrinkage caused by internal stress caused. There is the change of temperature distribution in materials element imbalance, is typical of surface and internal, thin wall and thick wall, bottom and top.

- Q:How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords