Silica Brick for Ceramic Kiln Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

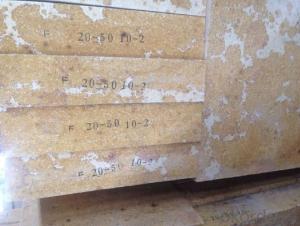

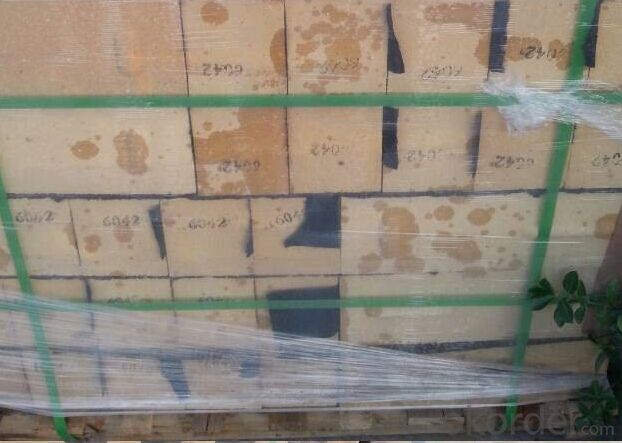

Ceramic firing kiln refractory Silica Brick Description:

Refractory Silica Brick is mainly made of top class silica, via shaping and burning under the high temperature,

Possesses high temperature resistant, high strength and low impurities, etc.

It is mainly used for blast furnaces and hot blast stove.

Features

Ceramic firing kiln refractory Silica Brick Advantage:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point

Applications:

Light weight silica bricks are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas

Ceramic firing kiln refractory Silica Brick specifications:

Product | AZM-1550 | AZM-1650 | AZM-1680 | |

Index | Index | Index | Index | |

chemical composition | SiC+SiO2 | ≥35 | ≥30 | ≥32 |

Al2O3 | ≥60 | ≥65 | ≥65 | |

Bulk Density(g/cm3) | ≥2.55 | ≥2.65 | ≥2.70 | |

Apparent Porosity (%) | ≤20 | ≤19 | ≤19 | |

Cold Crushing Strength(Mpa) | ≥80 | ≥90 | ≥100 | |

Refractoriness Under Load | ≥1550 | ≥1650 | ≥1680 | |

Thermal Shock Resistance | ≥10 | ≥15 | ≥20 | |

- Q:The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q:How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q:Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q:Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q:Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q:The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q:Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q:The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q:What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q:The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silica Brick for Ceramic Kiln Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords