Roof System-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roof System-1

Die umfassende Auswahl an unterschiedlichen Komponenten und Systemen ermöglicht es,

mit Schletter-Systemen nahezu jede Modulkonfiguration auf jedem Dach zu befestigen.

Durch unsere hochwertigen und durchdachten Komponenten erzielen Sie schnelle Montagezeiten und verlässliche Haltbarkeit mit statischem Nachweis.

Bei der Auswahl der für Ihr Dach am besten geeigneten Variante haben Sie die Wahl zwischen einer dachparallelen und einer aufgeständerten Lösung.

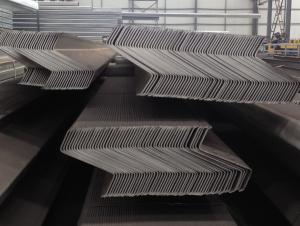

Leichte Aufständerung auf Trapezblech (5 - 7° Aufstellwinkel) für gerahmte Module

Konzipiert für gerahmte Module mit ca. 1,3 – 1,7 m Höhe in Hochkantmontage

Befestigung auf der U-konstruktion meist mittels Trapezblechschellen

Schnell und einfach zu montieren

Bessere Hinterlüftung

Bessere Selbstreinigung

Optimale Lastabtragung über die Dachhaut

Mehrertrag bei günstigem Systempreis

- Q:How does a solar mounting system affect the roof's waterproofing?

- A solar mounting system can potentially affect the roof's waterproofing if not properly installed. The attachment points and penetrations made for the mounting system can create potential entry points for water, leading to leaks and damage. However, with proper installation techniques such as using appropriate flashing and sealants, the impact on the roof's waterproofing can be minimized.

- Q:What is the difference between a roof-mounted and ground-mounted solar system?

- A roof-mounted solar system refers to solar panels that are installed on the roof of a building, while a ground-mounted solar system refers to panels that are installed on the ground. The main difference lies in the placement and orientation of the panels. Roof-mounted systems are commonly used when space is limited or to utilize the available roof area for solar energy production. On the other hand, ground-mounted systems are installed on the ground and can be placed at an optimal angle and direction to maximize sunlight exposure, making them more flexible in terms of positioning and potential energy output.

- Q:Can a solar mounting system be used in areas with limited access to solar crowdfunding platforms?

- Yes, a solar mounting system can definitely be used in areas with limited access to solar crowdfunding platforms. The availability or accessibility of crowdfunding platforms does not impact the functionality or usability of the solar mounting system itself. As long as there is sufficient sunlight and proper installation techniques are followed, the solar mounting system can be utilized effectively regardless of the crowdfunding platforms' presence or absence.

- Q:Can solar mounting systems be installed on sloped concrete roofs?

- Yes, solar mounting systems can be installed on sloped concrete roofs. However, the installation process may require additional measures to ensure proper stability and secure attachment to the roof surface. Professional assessment and expertise are recommended to determine the feasibility and appropriate installation methods for specific concrete roof slopes.

- Q:Are there any fire safety considerations when installing solar mounting systems?

- Yes, there are fire safety considerations when installing solar mounting systems. It is important to ensure that the mounting system does not obstruct access to firefighting equipment or emergency exits. Additionally, proper grounding and electrical connections should be implemented to minimize the risk of electrical fires. Regular inspections and maintenance of the system is also crucial to identify and address any potential fire hazards.

- Q:Are there any specific considerations for installing a solar mounting system in a seismic zone?

- Yes, there are specific considerations for installing a solar mounting system in a seismic zone. Seismic zones are prone to earthquakes, which can put additional stress on the solar panels and mounting structures. Therefore, it is important to ensure that the mounting system is designed and engineered to withstand seismic activity. This may include using reinforced materials, proper anchoring techniques, and conducting a thorough structural analysis to ensure the system can withstand the forces generated during an earthquake. Additionally, local building codes and regulations for seismic zones must be followed to ensure compliance and safety.

- Q:Can a solar mounting system be used with solar-powered trains?

- No, a solar mounting system cannot be directly used with solar-powered trains. Solar mounting systems are typically designed for stationary solar panels and are not suitable for installation on moving vehicles like trains. However, solar panels can be installed at train stations or along railway tracks to generate electricity that can be used for various purposes, including powering trains indirectly.

- Q:Can a solar mounting system be installed on a rooftop with a cedar shingle roof?

- Yes, a solar mounting system can be installed on a rooftop with a cedar shingle roof.

- Q:Can solar mounting systems be installed on historical or protected buildings?

- Yes, solar mounting systems can be installed on historical or protected buildings. However, the installation process may require certain considerations and modifications to ensure minimal impact on the building's historic integrity or protected status. This may involve using non-penetrating mounting techniques, such as ballasted systems, to avoid damaging the structure. Additionally, it is important to consult local authorities and preservation organizations to ensure compliance with any regulations or guidelines specific to historical or protected buildings.

- Q:Can solar mounting systems be installed on metal roofs?

- Yes, solar mounting systems can be installed on metal roofs. In fact, metal roofs are often considered ideal for solar panel installation due to their durability, strength, and ease of installation. The metal roof provides a stable and secure base for the solar panels, ensuring a reliable and long-lasting solar energy system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roof System-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords