Resistance Black HDPE Geomembrane for Pond Liner with Suitable Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Resistance Black HDPE Geomembrane for Pond Liner:

Our high density polyethylene (HDPE) geomembranes provide an impermeable barrier against a wide range

of solids and liquids. They exhibit excellent chemical and UV resistance, impermeability, and high yield and

welded seam strengths, which is widely used as the liner.

Main Features of Resistance Black HDPE Geomembrane for Pond Liner:

1.Long life, anti-aging, roof material can be more than 20 years, underground can be more than 50 years.

2. Good tensile strength, high elongation.

3. Good high/low temperature flexibility

4.Easy to construct, no pollution.

5. Good anti-corrosive ability, can be used in special area

6.Various colors are available

Specifications of Resistance Black HDPE Geomembrane for Pond Liner:

a) Density ≥ 0.94g/m²

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

f.) Permeability Coefficient ≤1.0xe-13g.cm/(cm2.S.Pa)

g.) -70oC Low Temperature Impact Brittle Property: good.

h.) Chemical Resistance: at 80oC, marinated in 5g/L Nacl for a long time, it will not erode or swell.

Applications of Resistance Black HDPE Geomembrane for Pond Liner:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

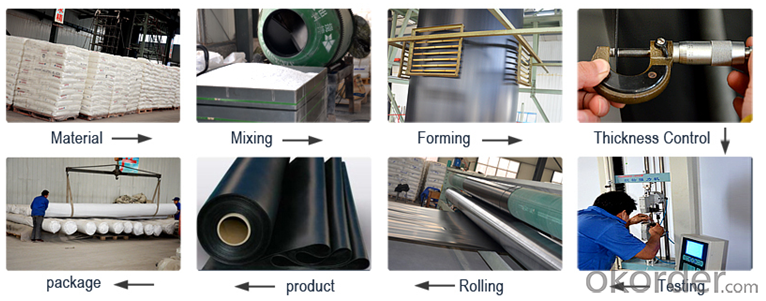

IMages of Resistance Black HDPE Geomembrane for Pond Liner:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Is the thickness gauge for lacquer film precise?

- Under normal circumstances it is relatively accurate. It may be inaccurate under special occations. After all, every product has its particularity. The thickness gauge is used to measure the thickness of materials and objects. It is usually used to measure the thickness of the products (such as plate, strip, film, paper and metal foil) in industrial production. There is radioactive thickness gauge that takes advantages of the α-rays, β-rays, γ-rays; ultrasonic thickness gauge that takes advantages of the ultrasonic frequency changes; eddy current thickness meter that takes advantages of the vortex principle; thickness gauge that takes advantages of the principle of mechanical contact measurement.

- Q:How are geomembranes tested for dimensional stability?

- Geomembranes are tested for dimensional stability through a series of standardized tests, such as the dimensional stability test ASTM D1204. This test involves subjecting the geomembrane to controlled temperature and humidity conditions, and measuring any changes in dimensions. Additionally, other tests like the tensile testing and elongation at break tests are conducted to assess the geomembrane's ability to maintain its shape and size under different conditions.

- Q:What is the one-way membrane?

- The architectural glass film. It can only see the outside from the inside, but the outside can not see the inside.

- Q:What are the advantages of using geomembranes in canal linings?

- There are several advantages of using geomembranes in canal linings. Firstly, geomembranes act as a barrier that prevents water leakage, ensuring efficient water conveyance and minimizing water loss. Secondly, geomembranes are highly durable and resistant to UV radiation, chemicals, and punctures, increasing their lifespan and reducing maintenance costs. Additionally, these linings help to control seepage and prevent soil erosion, thereby preserving the structural integrity of the canal. Lastly, geomembranes are flexible and adaptable, allowing for easy installation and customization to fit different canal shapes and sizes.

- Q:How are geomembranes tested for permeability?

- Geomembranes are tested for permeability using a variety of methods such as the falling head test, constant head test, and the ASTM D5084 test. These tests involve measuring the rate of water flow through the geomembrane under controlled conditions to determine its permeability characteristics.

- Q:What are the manufacturing techniques of electrothermal?film?

- The so-called mix design is the mixing ratio of raw materials used in heating film, this ratio varies with the purposes of films. The basic matters should be considered in designing: 1. impedance change rate. 2. hardenability prediction of the film after heating. 3. density (considering construction quality). CAD program is used in graphic design, painting process, after plasma treatment on the film, then paste the designed circuit with slurry which uses carbon and silver as main raw materials. Compared with previous silk screen type painting equipment, the DST painting equipment with metallic pattern has precise pattern and durability, is suitable for mass production of heating treatment in order to keep the quality of the heating part, it must be processed with high temperature. In order to prevent the deformation or damage of films in molding, and maintain a high quality, the temperature regulation mode of high precision temperature distribution is selected. In order to improve the system precision, automatic air volume control of hot air recirculation, foehn and ratio control is set. Strong chemical binding of insulating coatings of EVA and PE produces a very stable compound, which Provides guarantees for has fully chemical inertness, heat resistance and excellent stability. Although the material composition varies with temperatures, but the heating film that has demanding requirements on stability is world-class high performance polyester film which is now from SKC company. Quality inspection, in accordance with UL and CE certification standards of reliability assessment, carry out sampling inspection and full inspection. (test item) disruptive test, impedance variation rate, tensile strength test, insulation test.

- Q:Is electrothermal film a big consumer of electricity?

- It consumes 60-120 watt electricity per square meter. . . It consumes 0.6-1.2 kilowatt-hours electricity in 10 hours every square meter. After electrified, it keeps a heating power of 220W before it reaches the normal temperature in the initial half an hour.

- Q:What are the requirements for geomembranes used in heap leach pads?

- The requirements for geomembranes used in heap leach pads include a high level of chemical resistance to withstand the aggressive chemicals used in the leaching process, excellent puncture resistance to prevent leaks, low permeability to minimize fluid migration, and UV resistance to withstand prolonged exposure to sunlight. Additionally, the geomembranes should have good tensile strength and flexibility to accommodate any subsidence or settlement in the heap leach pad.

- Q:Can geomembranes be used in landfill capping?

- Yes, geomembranes can be used in landfill capping. They are often used as a barrier layer to prevent the migration of contaminants and gases from the landfill into the surrounding environment. Geomembranes provide a reliable and durable solution for landfill capping, helping to protect the soil and water quality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Resistance Black HDPE Geomembrane for Pond Liner with Suitable Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords