Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

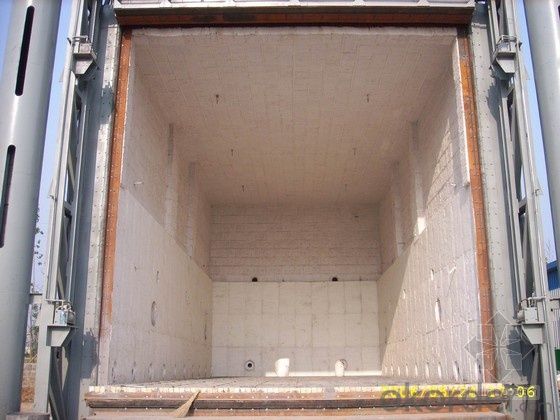

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:Refractory GJM Mullite Insulation Brick B-6

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-6

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-6

- Q:Are insulating fire bricks resistant to carbon dioxide?

- Yes, insulating fire bricks are resistant to carbon dioxide.

- Q:Can insulating fire bricks be used in applications involving molten metal?

- Yes, insulating fire bricks can be used in applications involving molten metal. Insulating fire bricks have high heat resistance and low thermal conductivity, making them suitable for withstanding the extreme temperatures generated by molten metal. They can be used in applications such as furnaces, kilns, and foundries, providing insulation and protection against heat transfer.

- Q:What materials are used to make insulating fire bricks?

- Insulating fire bricks are made from a variety of materials that possess high thermal insulation properties. The most common material used in the production of these bricks is a type of clay known as kaolin clay. This clay is mixed with other additives such as alumina, silica, and zirconium to enhance its insulating properties and increase its resistance to high temperatures. In addition to clay, other materials like sawdust, vermiculite, perlite, and calcium silicate are also sometimes added to the mixture to further improve the insulation capabilities of the bricks. Overall, the combination of these materials allows insulating fire bricks to have low thermal conductivity, high heat resistance, and excellent insulation qualities, making them suitable for a wide range of industrial and domestic applications.

- Q:Are insulating fire bricks safe to use?

- Insulating fire bricks are generally safe to use when used properly and in accordance with the manufacturer's instructions. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for applications such as lining kilns, furnaces, and fireplaces. Insulating fire bricks are made from lightweight materials such as alumina, silica, and other refractory materials. They are designed to minimize heat transfer, thus preventing the escape of heat from the enclosed area. This not only improves the energy efficiency of the system but also enhances safety by reducing the risk of overheating and potential fires. When using insulating fire bricks, it is essential to ensure that they are installed correctly and securely. Proper installation includes providing adequate support and reinforcement to prevent collapse or shifting of the bricks. Additionally, it is crucial to use appropriate mortar or refractory cement to join the bricks together, ensuring a strong and stable structure. While insulating fire bricks themselves are considered safe, it is important to note that they may contain small amounts of trace elements or materials that can be harmful if released into the environment. Therefore, it is recommended to follow the manufacturer's safety guidelines, such as wearing gloves, goggles, and a dust mask when handling the bricks. Overall, insulating fire bricks are a safe and reliable choice for insulation in high-temperature applications. However, it is important to take necessary precautions during installation and follow safety guidelines to ensure their proper and safe use.

- Q:What are the types of building blocks?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q:Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic tile kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. They have low thermal conductivity, which means they help to retain heat within the kiln and prevent it from escaping, resulting in more efficient and effective firing of ceramic tiles. Additionally, their lightweight nature makes them easy to handle and install in the kiln structure. Overall, using insulating fire bricks in the construction of ceramic tile kilns can help improve energy efficiency, reduce heat loss, and ensure consistent and controlled firing temperatures.

- Q:Are insulating fire bricks resistant to phosphorus pentoxide?

- Yes, insulating fire bricks are resistant to phosphorus pentoxide.

- Q:Can insulating fire bricks be used in the construction of thermal insulation walls?

- Yes, insulating fire bricks can be used in the construction of thermal insulation walls. Insulating fire bricks are specially designed bricks that have a low thermal conductivity, which means they are excellent at preventing the transfer of heat. This makes them ideal for use in thermal insulation applications. When constructing thermal insulation walls, insulating fire bricks can be used as the primary material or in conjunction with other insulation materials such as foam boards or mineral wool. These bricks are typically lightweight, which makes them easier to handle and install. They also have high temperature resistance, allowing them to withstand the heat generated by fireplaces, ovens, or other heat-producing appliances. Insulating fire bricks offer several benefits for thermal insulation walls. They help to minimize heat loss or gain, thereby improving energy efficiency in buildings. They also help to reduce noise transmission, making them suitable for soundproofing applications. It is important to note that insulating fire bricks may not be suitable for all types of walls or building structures. Factors such as building codes, environmental conditions, and specific requirements of the project should be considered when determining if insulating fire bricks are the appropriate choice for thermal insulation walls. Consulting with a professional architect or engineer is recommended to ensure the best insulation solution for a specific construction project.

- Q:What industries commonly use insulating fire bricks?

- Insulating fire bricks are commonly used in industries such as steel, aluminum, ceramics, glass, and cement production, as well as in various high-temperature applications like furnaces, kilns, incinerators, and thermal insulation systems.

- Q:What is the typical flexural strength of an insulating fire brick?

- The typical flexural strength of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, on average, insulating fire bricks have a flexural strength range of 1-10 megapascals (MPa).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords