PVC/PU Conveyor Belt with Different Surface Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt with Different Surface Pattern

Features:

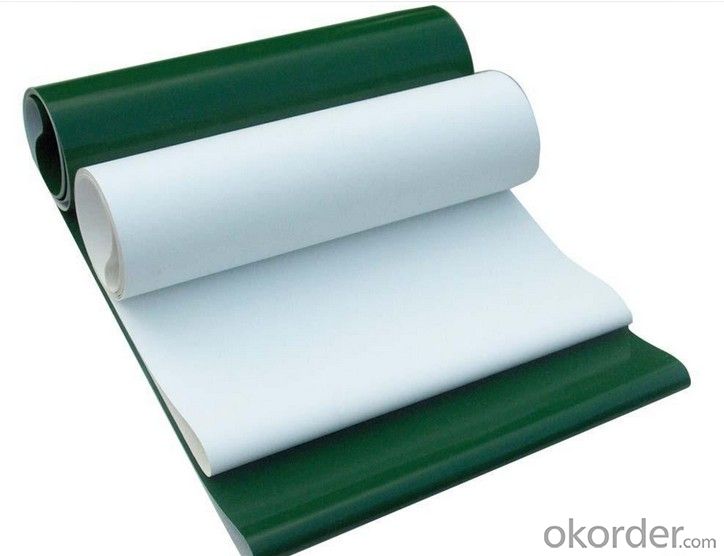

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

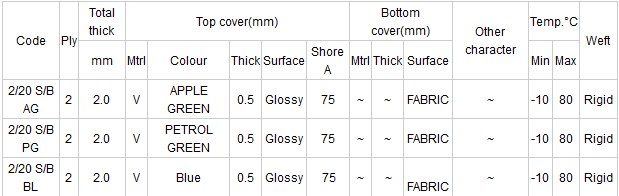

4.Color:Apple Green,Petrol Green,Blue,Black,etc

5. Various surfaces with high, medium and low coefficient friction

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

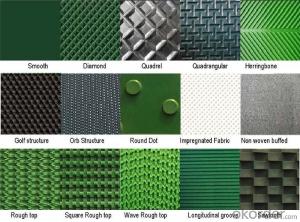

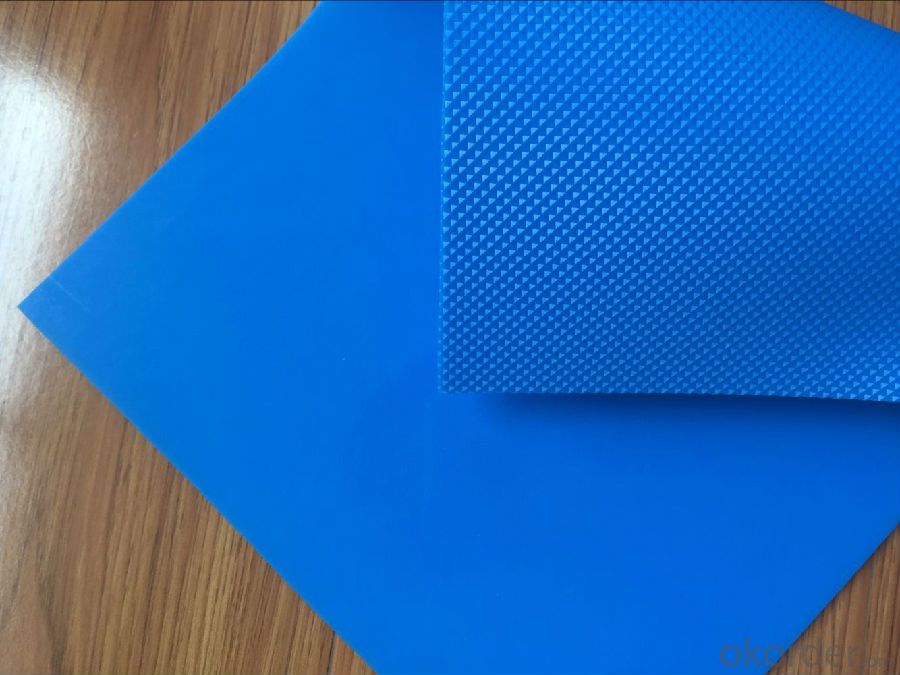

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.Specifications:

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How do I maintain an olive net?

- To maintain an olive net, there are a few key steps you can follow. Firstly, ensure that the net is properly installed and securely fastened to the surrounding structures or supports. Regularly inspect the net for any damages or tears, and promptly repair or replace any sections that are compromised. It is also important to regularly clean the net to prevent debris buildup, which can lead to damage or decrease its effectiveness. During the offseason, store the olive net in a dry and protected area to prevent damage from weather conditions. Overall, regular inspection, cleaning, and proper storage are essential for maintaining the longevity and effectiveness of an olive net.

- Q:Can olive nets be used in combination with organic fertilizers?

- Yes, olive nets can be used in combination with organic fertilizers. These nets are primarily used to protect olive trees from pests and adverse weather conditions, while organic fertilizers are used to enhance soil fertility and promote healthy growth of the olive trees. By using both olive nets and organic fertilizers, farmers can effectively protect their olive trees from external threats and provide them with essential nutrients in an eco-friendly manner.

- Q:Can olive nets be used in regions with limited labor availability for hand harvesting?

- Yes, olive nets can be used effectively in regions with limited labor availability for hand harvesting. Olive nets are designed to catch the olives as they fall from the tree during mechanical harvesting methods. This eliminates the need for extensive manual labor and makes the harvesting process more efficient. Additionally, the use of olive nets can help reduce the dependency on human labor, making it viable even in regions with limited workforce availability.

- Q:How do olive nets prevent fruit theft in the orchard?

- Olive nets prevent fruit theft in the orchard by creating a physical barrier that covers the entire tree, making it difficult for thieves to access the fruits. The nets are tightly woven and securely fastened around the tree, deterring unauthorized individuals from reaching the olives. Additionally, the nets provide protection against birds and other pests that may attempt to consume or damage the fruit.

- Q:Can olive nets be used in regions with limited access to pest control chemicals?

- Yes, olive nets can be used in regions with limited access to pest control chemicals. Olive nets are used to protect olive trees from pests like birds and insects by physically covering the trees and preventing them from accessing the fruits. This method is a natural and chemical-free alternative to pest control. It can be particularly useful in regions where access to pest control chemicals is limited or unavailable, allowing farmers to protect their olive crops without relying on synthetic chemicals.

- Q:Can olive nets be used to improve fruit quality?

- Yes, olive nets can be used to improve fruit quality. Olive nets are placed over the olive trees to protect the fruit from damage caused by birds, insects, and harsh weather conditions. By preventing external factors from affecting the fruit, olive nets help maintain its quality and prevent blemishes or deformities. Additionally, the nets create a microclimate that can enhance the ripening process, resulting in better taste and aroma. Overall, the use of olive nets is an effective strategy to enhance fruit quality and ensure a successful harvest.

- Q:Can olive nets be used on olive trees grown in arid climates?

- Yes, olive nets can be used on olive trees grown in arid climates. Olive trees require protection from extreme heat and sun exposure, and using nets can provide shade and reduce evaporation, helping to conserve water and create a more favorable microclimate for the trees. Additionally, nets can prevent pests and birds from damaging the olives, ensuring a better yield.

- Q:How to mend cracks in a plastic bucket?

- Depending on the material of the plastic tub and the location of the hole:If the plastic is PP, only hot melt, the home unconditionally;If HIPS, GPPS, ABS ab.

- Q:How does an olive net help prevent damage to the olives during harvesting?

- An olive net helps prevent damage to the olives during harvesting by creating a protective barrier that catches the falling olives. This prevents them from hitting the ground and potentially getting bruised or damaged.

- Q:What do you mean by the release angle of plastic parts?

- Determination of release inclination(1) the higher the accuracy of the product, the smaller the taper of the discharge.(2) larger size products shall be of a smaller stripping slope.(3) the shape of the product is complex and difficult to release, so the larger slope should be used.(4) product shrinkage rate, the slope should be increased.(5) reinforced plastics should be made of high angle. Plastic containing lubricant can be made of small slope.(6) the thickness of the product is large and the slope should be large.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC/PU Conveyor Belt with Different Surface Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords