PVC Co-extruded Foam Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

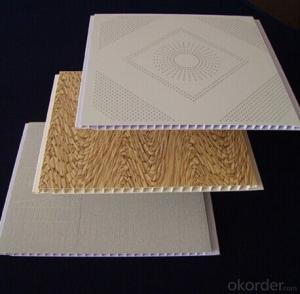

PVC Co-extruded Foam Sheet is made by special process, technique and equipment. The both surfaces of the sheet is not foam but rigid, while only the core is foam. It is like a sandwich board with thin surfaces. The advantage of this product is its hard surface like Rigid PVC sheet but in lighter weight and lower cost.

Length: 2440mm, 3050mm, 5800mm, any length available

Width: 1220mm

Thickness: 3-18mm

Density: 0.5-0.9g/cm3

Surface: Glossy

Color: White

Applications

Furniture making, especially for the furniture in moisture environment.

Anywhere or board needs hard surface.

Thermoformed parts.

Indoor and outdoor decoration.

Walls & partitions, wall cladding.

Advertising field, like sign board.

Features

Waterproof, perfect material for the moisture environment.

Hight Rigidity

Light weight, easy to install

Excellent electric insulation properties

High weatherability

Easy process, it can be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

- Q:Pvc foam board hardness how ah? Does anyone know not? Can you tell me?

- can.Co-extruded surface can reach Shore 85D, crust surface 60-65D

- Q:Whenever we run hot water in the kitchen (faucet or dishwasher), a loud knocking noise comes from the PVC pipes in the basement. It seems to be coming from the main drain pipe which is about 3 or 4 inches in diameter, and it knocks right along the ceiling joists. After a few minutes the knocking stops. Any suggestions?

- Insert some foam rubber between the pipe and joists. I would guess that the noise is from the water supply pipes rather than the drain though. Secure the water lines with metal strapping that has holes in it. If the water lines are plastic, lay a piece of rubber between the pipe and strap to prevent cutting from vibration. Normally this strapping is used for hanging duct work.

- Q:Uv printer hit pvc board why a scraping off Before the scraping is very good scraping off, and now a nail plan, plans to fall out

- Can be analyzed from two aspects: Ink and coating problems (this can only be resolved through the sale) PVC board problem (this can ask the supplier, the board and before there is no difference, because the higher the density of printed materials, UV ink adhesion worse)

- Q:What is the difference between pvc floor and marble floor?

- Pvc floor foot feeling more comfortable, the friction is not easy to walk than the marble is not easy to tired, sound-absorbing performance, plastic than marble strong, strong color performance, maintenance and more convenient.

- Q:What models are pvc boards?

- Soft pvc hard pvc polycondensation pvc expansion poly pvc / modified pvc.

- Q:How does PVC hardness dictate?

- PVC can be divided into soft PVC and hard PVC. Soft PVC is generally used for the floor, ceiling and leather surface, but because the soft PVC contains softeners (which is the difference between soft PVC and hard PVC), easy to become brittle, easy to save, so its use has been limited. Hard PVC does not contain softener, so flexible, easy to shape, not brittle, non-toxic and pollution-free, long storage time, so it has great development and application value.

- Q:My family just moved into a new house in Maryland. In the basement there is a finished part and an unfinished part we use for storage. Over the last few days, we noticed this smell/odor coming from the basement, most notably from the unfinished side. We discovered a large PVC pipe which dead-ends has been leaking this dark brown water, and identified this water as the source of the smell.Does anyone know what this dead-end pipe is for?Thanks a bunch!

- Well, okorder /... and that will stop the leak until you can make more permanent repairs. That silicone tape is pretty effective, I've used it on pressure lines, and in fact have a repair on a pressure line that is now 2 years old. Don't frown at that, we've been planning to make changes in that building for two years and I keep thinking the plumbing's going to get rearranged, or else I would have made a permanent repair already...but even so, it hasn't leaked yet. IMPORTANT: tell everyone not to flush any toilets, run any sinks, run any laundry or showers or any other water while you've got that pipe open. Because that would be, you know, gross. Good luck with it.

- Q:Home decoration kitchen bathroom ceiling selection of PVC or integrated board, which is better point

- Integrated board is still better point, the home of the PVC board with less than four years, now looked dirty, it is ugly.

- Q:Soft pvc board how to install it? How is the market price?

- According to market conditions

- Q:PVC floor discoloration how to deal with?

- Protective agents can be used on a regular basis. That is, resin coating. You can also add a small amount of abrasive when cleaning. Must use clean abrasive, not polishing abrasive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Co-extruded Foam Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords