Used for Ceiling and Wall,As Hotels Commercial Buildings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Price Terms : FOB/CIF

Payment term : 30% prepayment , 70% before shipment

Supply Ability : 15 produce line , 17000M2each day , 20 *40 HQ /month

Minimum Order : one 20 container

Product Advantages:

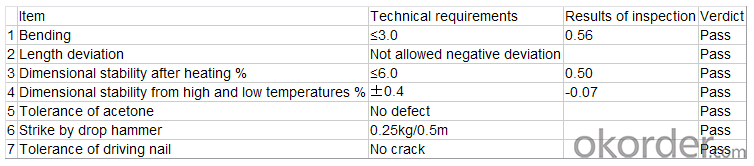

Specification | Thickness(mm) | Width(cm) | Weight(kg/m2) |

6 | 18 | 1.8 | |

5 | 20 | 1.6 | |

6 | 20 | 1.8 or 2.0 | |

6 | 25 | 1.8 or 2.0 | |

6.75 | 25 | 2.4 | |

7 | 20 | 2.0 or 2.3 | |

7 | 59.5 | 2.5 | |

7 | 60.3 | 2.5 or 3.0 | |

7.5 | 25 | 2.4 | |

8 | 20 | 2.5 or 2.625 | |

8 | 25 | 2.3 or 2.5 | |

8 | 16 | 3.125 | |

8.5 | 20 | 2.5 or 3.5 | |

9 | 20 | 3.0 or 3.15 | |

9 | 30 | 2.95 or 3.085 or 3.16 | |

9 | 25 | 3.2 | |

9.5 | 30 | 3.9 or 4.0 | |

9.5 | 10 | 3.5 or 4.0 | |

9.5 | 16 | 3.3 or 3.75 | |

9.5 | 20 | 2.625 or 3.5 or 3.75 or 4.125 | |

9.5 | 6 | 5.3 | |

11 | 20 | 4.4 | |

12 | 15 | 3.0 | |

12 | 20 | 3.9 | |

13 | 20 | 4.375 | |

15 | 20 | 4.75 | |

Length: 5.8m for 20'GP and 5.95m for 40'HQ. or according to customer requirement. | |||

Main Product Features:

1)Glossy PVC Panel (most common type)

2)Sub-glossy PVC Panel (Natural surface handing)

3) High-glossy PVC Panel (high-light surface handling)

Product Specifications:

Images:

- Q:Whenever we run hot water in the kitchen (faucet or dishwasher), a loud knocking noise comes from the PVC pipes in the basement. It seems to be coming from the main drain pipe which is about 3 or 4 inches in diameter, and it knocks right along the ceiling joists. After a few minutes the knocking stops. Any suggestions?

- your probably hearing the supply lines knocking against the drain pipe which can eventually lead to a failure in the supply line at a connection point or coupler. have somebody run the watewr while you go downstairs and check for movement in the pvc. if the pvc moves you will need a air hammer arrester, if no movement detected run each faucet individualy and see if the problem is in a valve

- Q:PVC crust foam board business standards or national standards

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality is in the high-end.

- Q:PV board, PVC board material properties

- PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc. ~ Our home now use PVC pipe, because the iron pipe is easy to suffer from the risk of ice in the winter, but if you use plastic or plastic wrap is PVC material if

- Q:How many years can I use a PVC

- Standard design PVC gusset life should be around 15 years ? Cut the fun of the conscience of the boss produced about 3 years of scrap products

- Q:Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You said the ground is not cement road level, there are a lot of holes, I do not know you are not the ground is the sand from the like, if there is a sand from the proposed you do not do cement self-leveling so that the quality of your floor There is no guarantee that the ground is not cement road Ping suggested that you do not do cement self-leveling and do not say how the effect of the cost is too high, the cement self-leveling to find someone to do the price of 15-25 yuan per square meter, and cement self-leveling Each can only do 2-4MM meters, that is to say that you want to make a good effect at least have to do 2 to 3 times, so the cost is too high, I do many years of PVC flooring, it is recommended that you shop The ground before the first to find a good way to find the mud on the ground so that you will be less to a lot of cost and the effect of the bottom out of the floor will be much better

- Q:I plant processing acrylic board PVC foam board KT board sun board PVC board acrylic board Hibiscus board foam board plastic plate aluminum plastic plate transparent board density board

- Not processing PC board ah, we process PC board, you can exchange

- Q:With the area and thickness of the KT board and PVC board which is more expensive?

- Pvc also has a very cheap, that is, the density of the foam is not high. Kt board also has a high density, more expensive. This is generally very rare. ? Ordinary common pvc board expensive

- Q:, Pvc board, wood keel ceiling, contractors, not packing materials, buy their own wooden screws, mainly to do the bathroom, toilet kitchen, open at 4 meters above, how much money a square meter can do

- Fifteen dollars per square, the premise is flat top. Southern words about twenty or so. Specifically your description of your area

- Q:Pvc floor green? Can you pave it in the bedroom?

- Pvc floor is absolutely environmentally friendly. General pvc floor of the main raw material is PVC, is environmentally friendly non-toxic renewable resources, relative to the wood floor of formaldehyde and other harmful substances, pvc floor environmental performance has an absolute advantage. Pvc plastic flooring is the main raw material is polyethylene plastic, and the selection of non-radioactive marble powder. Polyethylene plastic is environmentally friendly non-toxic renewable resources, in the production process all added ingredients are completely non-toxic non-radioactive, does not contain any heavy metal its environmental protection is no need to worry, it is real, green green floor. At present, many people do not understand this floor,

- Q:Pvc foam board and wood-plastic plate difference?

- Wood-plastic board generally add wood for the powder or bamboo powder, rice bran, etc., there are some wood-plastic plate which has added foam agent. Foam plate section with holes, the density is light

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Used for Ceiling and Wall,As Hotels Commercial Buildings

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords