PVC Gypsum Cheap Suspended Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

The PVC gypsum ceilings are a combination of plaster board produced from high

quality natural gypsum which is free of any harmful substances, selected anti

static PVC/Vinyl facing and aluminum PET foil and excellent kind of glue plaster.

The product is available in various attractive designs suitable for different applications and usages.

It is widely used in areas such as offices, schools, shopping malls, Restaurants, hospitals and Laboratories, etc.

Material: Gypsum Board, non asbestos, sulfate free

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

3.Image

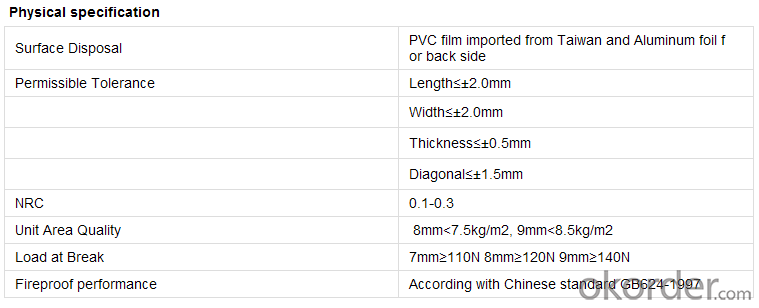

4.Detailed Specification

5.FAQ

Applications

Fireproof and waterproof

Dustproof and moth-resistant

Thermal insulation

Environmental and healthy

Plentiful and fashionable surfaces

Easy Installation and easy to clean

- Q:Home wall rain easy to seepage, the decoration of the wall can be what moisture-proof material? Heard that PVC board is good, can be used for the wall?

- To use the Great Wall board all-inclusive, but still have to solve the problem of seepage, or else how to do is not a long time

- Q:Where do you have to sell the PVC board for the 2000x1200x20 specification?

- See your question for a long time no one to answer, but the question expired no one answered will be deducted and your reward points will be confiscated! So I'll give you a few suggestions: One, you can choose to ask questions in the correct classification, so that you will answer the question of the number of people will be more, the answer will be more people. Second, you can go to your question related professional website forum to see, where gathered a lot of professionals, we can solve the problem for you. Third, you can ask your online friends to ask friends, they will be more sincere and enthusiastic for you to find the answer, and even to the relevant site to search directly. Fourth, a lot of online professional forums and knowledge platform, there are a lot of information, I encountered professional problems is always on the forum to find a solution. Five, your question asked some fine, clear some! Make it easier to understand what it means to understand! Thanks for taking my advice!! /.,]]]

- Q:Wall paint and hang pvc board comparison who is more suitable? How are the operation?

- Stone wall is also a common external wall hanging plate, he has a wall hanging board most of the functions required, but also by many buildings used. Stone defects, one is some stone radiation, will cause some damage to the human body; Second, the stone is not renewable resources, expensive; Third, the weight of the external walls of the wall and steel structure requirements are higher. I hope useful to you!

- Q:Will the PVC transparent board with what glue can put two together?

- PVC glue on the line

- Q:Production of PVC foam board of raw materials are what ah? What is the role of ah?

- PVC resin: This is the most important raw materials, foam substrate, the production of PVC foam sheet generally use P-700-type PVC resin, the processing of its gelation speed, processing temperature is relatively low, product quality and density Easy to control. In the production of leather foam PVC sheet, in order to improve product quality, strict control of product density and thickness fluctuations, more use of P-700-type vinyl PVC resin. In the production of free foam PVC sheet, from the lower production costs to consider, there are many manufacturers using calcium carbide P-700-type PVC resin

- Q:Who knows, acrylic board, organic board, color plate, PVC board What is the difference.

- I suggest you refer to the relevant plastic network or footwear network. These can be consulted. Detailed description, time consuming too much!

- Q:Do the closet door density board is good or PVC good

- Hello friends! 1, MDF is a natural wood fiber as raw material, broken, fiber separation, drying after the application of synthetic resin, in the heating and pressing conditions, the suppression of a plate. Features: the internal structure of the uniform, smooth surface, bearing a good, easy to deformation, beautiful effect 2, PVC is a chemical substance, the main component of polyvinyl chloride, the top surface of the membrane is a paint. Features: than natural materials, can not rule out the toxicity and odor, directly used as a door, the surface bright, no wood effect, high temperature easy to bubble deformation, cost cheap. In view of the above two points, recommend MDF wardrobe doors, MDF more environmentally friendly, beautiful and better, and some better stability.

- Q:Pvc foam board what materials?

- Product Usage Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling.

- Q:PVC flooring and wood flooring which is better?

- Of course, is a good wooden floor, PVC is only the recent popular new products; The advantages of wood flooring: fire, fitness, moisture and other advantages

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Gypsum Cheap Suspended Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords