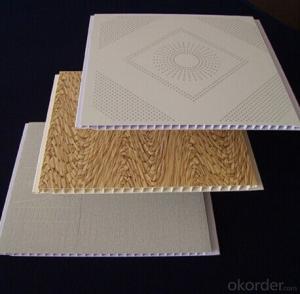

Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Newly designed PVC Ceiling Panels:

1.ISO9001,Soncap,CE&SGS

2. Easy-clean surface & maintenance free

3.Various designs & spec

Newly designed PVC Ceiling Panels

Company Information

We are a professional PVC Ceiling panels manufacture since 1992, offering hundreds of patterns and colors of PVC panel and monthly output up to 480,000 Sqm.

Product Advantages:

Normal Packing: 10 pcs per PE Film Package with carton End cap at both end of the package.

Special Packing: 1. transparent film between two panels to protect the surface; 2. carton box with 10 pcs or 20 pcs per carton; 3. as requested. Special Packing fees extra.

Shipping: 7-10 days upon receipt of deposit for a 20GP and 10-15days for a 40'HQ.

.

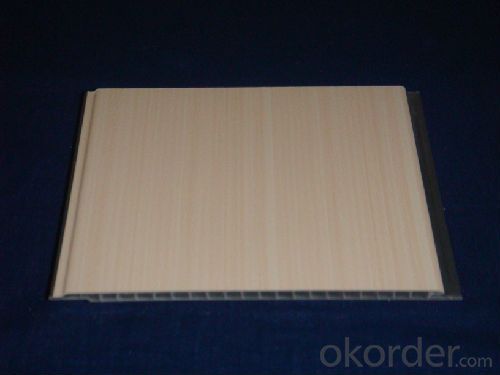

Product Description

20cm*7.5mm groove PVC ceiling panels, for Africa Countries, India, Mid-east and Europen markets,with CE, ISO9001:2008, SONCAP,SGS certification

Different types of PVC ceiling we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC ceiling on the market:

Thickness: 4mm/4.5mm/6mm/7.5mm/9mm/10mm/11mm/12mm

Length: 3m-5.95m

Width: 200mm, 250mm, 300mm, 600mm

PVC percentage: 35%-75%

Any other specifications are also available here.

Main Product Features:

| Newly Designed PVC Ceiling Panels | ||||||||

Lucky PVC | Width | Thickness | N.W. | Packing | Loading in 20’GP (5.8m length) | Loading in 40'HQ (5.95m length) | ||

| mm | mm | Kg/Sqm |

| packages | amount/Sqm | packages | amount/Sqm |

Flat Panel | 100 | 7.5 | 2.2 | 10 pcs/PE film package | 736 | 4268.8 | 1610 | 9579.5 |

| 150 | 7.5 | 2.3 |

| 496 | 4315.2 | 1084 | 9674.7 |

| 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 1829 |

|

| 10 | 3.8 |

| 276 | 3201.6 | 598 | 7116.2 |

| 240 | 9 | 2.7 |

| 254 | 3535.7 | 566 | 8082.5 |

| 250 | 4 | 1.5 |

| 558 | 8091 | 1070 | 15916 |

|

| 4.5 | 1.65 |

| 495 | 7177.5 | 941 | 13997 |

|

| 6.5 | 2.1 |

| 333 | 4828.5 | 758 | 11275 |

|

| 7 | 2.2 |

| 315 | 4567.5 | 704 | 10472 |

|

| 7.5 | 2.3 |

| 297 | 4306.5 | 600 | 8925 |

|

| 8 | 1.6 |

| 279 | 4045.5 | 614 | 9133 |

|

| 11 | 3.4 |

| 189 | 2740.5 | 432 | 6426 |

| 300 | 9 | 2.3 |

| 198 | 3445.2 | 429 | 7658 |

Groove Panel | 200 | 6 | 1.8 |

| 462 | 5359 | 910 | 10829 |

|

| 7.5 | 2.2 |

| 364 | 4222.4 | 785 | 9341.5 |

| 250 | 8 | 2.7 |

| 279 | 4045.5 | 590 | 8776 |

| 300 | 9 | 3 |

| 176 | 3062.4 | 418 | 7461.3 |

Wave Panel | 250 | 8(four) | 3.2 |

| 238 | 3451 | 564 | 8389.5 |

| 250 | 8(three) | 3.7 |

| 238 | 3451 | 564 | 8389.5 |

Suspended Ceiling | 595 | 7 | 2.1 | 20pcs/carton | 468 | 3313.7 | 1197 | 8475 |

| 605 | 7 | 2.2 |

| 450 | 3294.2 | 1160 | 8213 |

Product Specifications:

Application of pvc ceiling

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

1, Household Ornament: Wall and ceiling of indent independent house bathroom

2, Public and Management Place: Toilet of building and hall

3, Common Office: Ceiling of business Place

Feature of pvc ceiling:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

4) Interior decoration for ceiling. Easy clearing, healthy and environmental.

Images:

- Q:Pvc how to heat the deformation of soft board, to make their own shape

- Small on the hair dryer, the factory on the infrared or oven heating

- Q:Allow phonetic typing Pvc panel market now how to? Want to do the next trade. Please help me find this station?

- your question is total garble what are you looking for ? try your search bar and learn to make a complete question

- Q:Pvc transparent board is building materials?

- Branch Po PVC transparent board: the product is the introduction of foreign advanced technology, the use of advanced imports of raw and auxiliary materials produced by a high-strength, high transparent plastic sheet. The product is high strength, high transparency, good weather resistance, non-toxic, health, physical properties better than plexiglass. Widely used in equipment protection board, interior, drinking water tank, liquid level display. Product color: white, sapphire blue, brown, brown and so on Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm

- Q:Bamboo flooring and PVC flooring which is good

- PVC flooring is good, in Europe and America has long been popular for decades, the domestic medical system from the 90's abroad study and found that Europe and the United States hospitals are using PVC plastic flooring, began to introduce the domestic, and now in many medical, commercial, use. But the home improvement or use, however, with some understanding of the relationship between people it Wood floor wear test is about 13000 turn, PVC plastic floor is 300000 rpm, bamboo flooring and wood floor should be almost it And PVC plastic floor wear, anti-skid, antibacterial, no deformation, easy to care, etc. is still very advantageous.

- Q:KT board and PVC board, as well as ABS board What is the difference between ah

- Kt board is polystyrene material (lunch box material) foam out of the plate, the biggest feature is the light mainly used for indoor advertising; Pvc plate - also known as pvc foam board or Andy board, its chemical composition is polyvinyl chloride. Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling. (The general plastic pipe with this material is called pvc but not foam) ABS board ABS board ABS board is a new material in the sheet industry. Its full name is acrylonitrile / butadiene / styrene copolymer plate. English name Acrylonitrile-butdiene-styrene, is the largest production, the most widely used polymer. It will PS, SAN, BS various properties organically unified, both tough, hard, just equal balance of excellent mechanical properties. (Refrigerator, air conditioning these are used in this material)

- Q:I have an old house and recent found a spot on my ceiling where there is a watermark. upon prodding through i see that the spot where the large cast iron drainage pipe that runs to the basement that connects to the 6 PVC bathroom drainage pipe upstairs has developed a small leak. There is a small spot where this white stuff (looks old) has chipped off and that is where the leak is coming from. Nothing major, but still a drip....drip....drip...enough to ruin the drywall, and enough to be fixed. I need to know what kind of material (pvc cement, caulk, etc) i would use to seal up that joint, as ripping it all out isnt an option. Something that preferrably would set when its wet (if possible) as it seems to be nonstop dripping.thanks for the help!

- Pvc Pipe Boot

- Q:PV board, PVC board material properties

- PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc. ~ Our home now use PVC pipe, because the iron pipe is easy to suffer from the risk of ice in the winter, but if you use plastic or plastic wrap is PVC material if

- Q:PVC ceiling plate how to disassemble

- First of all, you have to observe the buckle board, the general edge of the last piece is not a block, then this piece is not the whole piece is the last piece, but also to first remove a piece, Hold down the last piece of the hand to the wall hard push, to 2 side to push, light push side is not enough, you push this piece in the end, you will find and another side of the office has been divorced, and then You can directly win, and the second plate will remove the screws, the screws in the middle of the wood, directly screw down on it, the screw down and then pull down this board also down, and then Repeatedly, the top is removed!

- Q:My family just moved into a new house in Maryland. In the basement there is a finished part and an unfinished part we use for storage. Over the last few days, we noticed this smell/odor coming from the basement, most notably from the unfinished side. We discovered a large PVC pipe which dead-ends has been leaking this dark brown water, and identified this water as the source of the smell.Does anyone know what this dead-end pipe is for?Thanks a bunch!

- Well, okorder /... and that will stop the leak until you can make more permanent repairs. That silicone tape is pretty effective, I've used it on pressure lines, and in fact have a repair on a pressure line that is now 2 years old. Don't frown at that, we've been planning to make changes in that building for two years and I keep thinking the plumbing's going to get rearranged, or else I would have made a permanent repair already...but even so, it hasn't leaked yet. IMPORTANT: tell everyone not to flush any toilets, run any sinks, run any laundry or showers or any other water while you've got that pipe open. Because that would be, you know, gross. Good luck with it.

- Q:Pvc transparent board which are used

- Customers in the choice of a product at the same time the most concerned about the natural function, as the price of this key factor I think it is based on the establishment and function of the above, as long as your product customers with more confidence in the money others will not refuse. Pvc transparent plate surface hardness and high scratch resistance, with excellent anti-static function, impact resistance and chemical resistance of outstanding performance, compact design, of course, this is not the focus, the appearance is limited to human aesthetic point of view, really useful Not that of these. Pvc transparent sheet has a higher hardness and mechanical properties, but also a good electrical properties of the polymer, suitable for pharmaceutical, chemical anti-corrosion materials. Pvc transparent sheet of the screw with a special mixing function and high plasticizing capacity design. This design is easy to adjust the thickness of the plate more accurate, its flatness, lifting methods and the use of screw adjustment methods are very useful, pvc transparent plate independent control of the roller temperature control system can accurately control the pressure roller temperature, so that Thickness of the sheet is uniform. With automatic meter can set the product length, more perfect function

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Newly Designed PVC Ceiling Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords