Prepainted Galvanized Steel Coils

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 150000 tons per year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

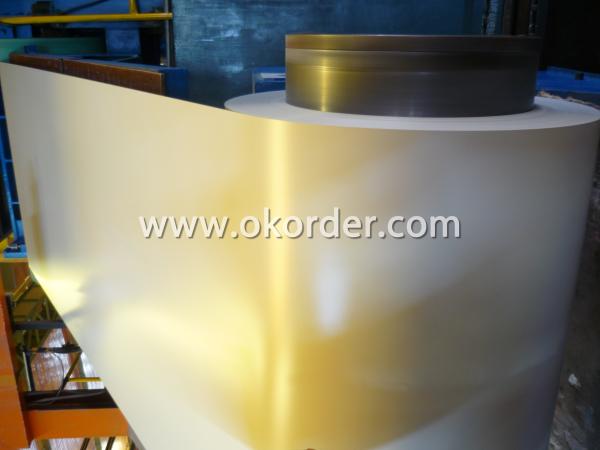

Prepainted Galvanized Steel Coils

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: OKLSTEEL

Specifications Of Prepainted Galvanized Steel Coils

|

Thickness 0.186-0.8mm (BMT) Width 1000-1250mm |

|

Zinc Coating 80-275g/m2 |

|

Color According to RAL color fan or as per request |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition OfPrepainted Galvanized Steel Coils

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data OfPrepainted Galvanized Steel Coils

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

Applications Of Prepainted Galvanized Steel Coils

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery Of Prepainted Galvanized Steel Coils

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Prepainted Galvanized Steel Coils

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q:Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- Hello! The reason is: 1. cold rolled flat plate is Kaiping;2. cold-rolled plates are negative tolerances.

- Q:My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- Steel toe boots around horses is a big no-no! horses are heavy enough to bend the steel and that could possibly cut into her foot. Even if it doesn't cut into her foot, the boot is ruined after the first time a horse does step on it. On the other hand, Mountain Horse and Ariat both make great winter riding boots.

- Q:I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- Jet gasoline definitely does get warm sufficient to soften the engines (the cores of that are created from titanium alloy, not steel). in actuality, jet engines could be in particular designed as a fashion to not soften below popular working situations. As for the engines vaporizing it incredibly is extremely not likely. They probable have been pulverized via the impact forces and the debris then melted interior the hearth.

- Q:How are steel coils inspected for bendability using bend testers?

- Bend testers are specialized machines utilized to inspect the bendability of steel coils, measuring their flexibility and resistance against bending. The inspection process involves multiple steps to guarantee precise and dependable outcomes. To begin with, the steel coil is prepared by securing it firmly in place, typically using clamps or other mechanisms to prevent any movement during testing. This ensures stability and enables consistent and repeatable measurements. Following that, the bend tester is set up according to the specified testing parameters. These parameters usually include the desired bend angle, the speed at which the bend is applied, and the number of cycles to be performed. The bend tester is equipped with a bending mechanism that applies a controlled force on the coil, simulating the bending conditions it may experience in its application or use. Once the bend tester is ready, the bending process commences. The machine gradually applies an increasing force to the steel coil until it reaches the desired bend angle. Careful measurement and monitoring of this force take place throughout the process to ensure accuracy. While the bending process is underway, the machine records and displays significant data, such as the applied force, the angle of bend, and any indications of cracking or other defects. This data is crucial for evaluating the bendability of the steel coil and determining its compliance with required standards. Once the desired bend angle is attained, the coil is released from the bending mechanism, allowing any residual stresses to relax. This relaxation period is essential for observing any potential spring-back effect, where the coil partially returns to its original shape after bending. The amount of spring-back is also measured and recorded for further analysis. Finally, the inspection results are analyzed to assess the overall bendability of the steel coil. If the coil meets the specified bendability criteria, it can be deemed acceptable for its intended application. However, if any cracks, fractures, or excessive spring-back are detected, further investigation and analysis may be necessary to identify the cause and determine appropriate corrective actions. In conclusion, bend testers play a crucial role in inspecting the bendability of steel coils. Through a controlled and systematic process, these machines accurately measure flexibility and resistance to bending, ensuring the quality and reliability of steel coils used in various industries.

- Q:What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils used in the electrical equipment industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.25mm to 3mm in thickness and 600mm to 2000mm in width. The inner diameter of the coil is typically around 508mm, while the outer diameter can vary from 800mm to 2000mm. These dimensions ensure compatibility with various electrical equipment manufacturing processes and enable efficient production.

- Q:I heard on some shows that you can carbonise steel by heating it red hot then dropping it in black oil. i cant find this no where online, and the process for commercial carbon steel is totally different. can you really carbonise regular steel by heating it to red hot then dropping it in regular black oil. i saw it on mythbusters once. when the made carbon steel hammers to test if 2 hammers smashed together will shatter

- Carburized steel is not the same thing as carbon steel. All steel has carbon in it, but carbon steel is defined as Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 1.04 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. Carburizing is a surface treatment. Dropping hot steel in oil is oil quenching. It might get a little carbon in the surface, but oil quenching is mainly used as a slightly slower quenching process than water quenching, not for carburizing. Once it starts cooling down the carbon won't diffuse in. Quenching is used to change the hardness. The simplest way to carburize steel is to pack charcoal around it and heat it to 900 C or so. Industrial processes use a gas like carbon monoxide, but that's mostly just for easier process control.

- Q:How are steel coils used in the production of electrical transformers?

- Steel coils are used in the production of electrical transformers as they provide the core structure for the transformer. The steel coils are wound with insulated copper wire to create the primary and secondary windings of the transformer, which allow for the transformation of electrical energy from one voltage level to another. The steel coil helps to conduct and distribute magnetic flux within the transformer, ensuring efficient energy transfer and reducing losses.

- Q:My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- There is no way you could make a 110 floor building out of concrete.

- Q:For example, (and this is weird) if I were wearing a steel collar and I needed some way to remove it, with limited supplies.Force is difficult because it would be around my neck.Chemical cominations are great- but they have to use VERY common products. And I'm not sure what to use.Other ideas?

- Your best bet would be a grinding wheel attached to a small electric motor. Even if you slipped, your skin is too soft to be cut by the dull wheel. Steel, however, is easily cut. But perhaps you don't have access to electricity or pressurized air to run such a tool. In that case, a simple file would work well, though you'd be somewhat more likely to injure yourself. If you had no tools, but access to whatever chemicals you wanted, you could try a weak acid. This would take a long time, and require constant scrubbing to bring fresh acid into the pits in the metal, but it would eventually eat through the collar.

- Q:How do steel coils contribute to the construction sector?

- Steel coils contribute to the construction sector in several ways. Firstly, they are used to manufacture structural components such as beams, columns, and steel frames, which provide strength and support to buildings and infrastructure. Secondly, steel coils are used to produce reinforcement bars that are embedded in concrete, enhancing its tensile strength and durability. Additionally, steel coils are utilized in the construction of bridges, pipelines, and other large-scale projects that require robust and long-lasting materials. Overall, steel coils play a vital role in the construction sector by providing the necessary materials for sturdy and resilient structures.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Mid East;Western Africa;Sourth America;southeastern Asia |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Prepainted Galvanized Steel Coils

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 150000 tons per year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords