Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI Steel Coil Images

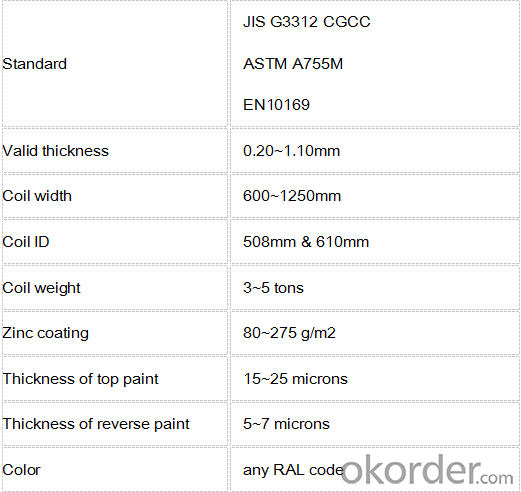

4.Pre-painted GI Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:I need to know where to go online to buy a steel cage for a wrestling ring.. Somebody please assist me?

- the only thing you can find is a bird cage because their is no way you can buy a steel cage unless you build it yourself

- Q:What are the different types of steel coil edges?

- Various steel coil edges exist, each possessing unique characteristics and applications. 1. Mill Edge: The most prevalent type, it is obtained by cutting the coil at the mill without undergoing any further processing or treatment. Mill edge coils have a natural, slightly rounded edge, making them suitable for a wide array of applications. 2. Slit Edge: Slit edge coils are created by cutting the coil across its width using a slitting machine. This results in a straight and smooth edge, making them ideal for precise measurements needed in automotive parts or electrical components. 3. Deburred Edge: Deburred edge coils have undergone an additional process to eliminate any burrs or sharp edges that may exist after slitting. This ensures safer handling and reduces the risk of damage during fabrication or installation. Deburred edge coils are commonly used in the construction industry, particularly for structural steel components. 4. Rounded Edge: As the name implies, rounded edge coils possess a curved edge profile achieved through a specific rolling process. This creates a smooth and curved edge, making them often utilized in applications prioritizing safety, such as the manufacturing of household appliances or kitchen equipment. 5. Sheared Edge: Sheared edge coils are produced by cutting the coil using shearing blades, resulting in a straight edge with a slight burr. While sheared edge coils may have a rougher finish compared to other edge types, they are still frequently used in applications that do not require a high level of precision, like general fabrication or shelving. In summary, the choice of steel coil edge depends on specific application requirements, including factors such as measurement precision, safety considerations, and aesthetic preferences.

- Q:How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils are both widely used in various industries for their strength and durability. However, there are some key differences between the two that should be considered when choosing the appropriate material for a specific application. One of the main distinctions between steel coils and stainless steel coils is the composition of the materials. Steel coils are made primarily of iron and carbon, with other elements added to enhance specific properties. On the other hand, stainless steel coils are made of iron, carbon, and a significant amount of chromium, which gives them their unique corrosion-resistant properties. Due to the presence of chromium, stainless steel coils offer superior resistance to corrosion, tarnishing, and rust compared to regular steel coils. This makes stainless steel coils particularly suitable for applications in environments with high humidity, moisture, or exposure to corrosive substances. In contrast, steel coils are more prone to rust and may require additional protective coatings or treatments to prevent corrosion. Another significant difference is the appearance of the two materials. Stainless steel coils have a shiny and reflective surface, giving them an aesthetically pleasing look. They are commonly used in applications where appearance is important, such as kitchen appliances, architectural structures, or decorative purposes. Steel coils, on the other hand, have a matte or dull finish and are often used in industrial applications where appearance is not a primary concern. In terms of strength, both steel and stainless steel coils offer excellent mechanical properties. However, stainless steel coils generally exhibit higher tensile strength and greater resistance to high temperatures. This makes them suitable for applications that require strength, such as construction, automotive, or aerospace industries. Lastly, cost is a factor that should be considered when comparing steel coils to stainless steel coils. Steel coils are generally more cost-effective than stainless steel coils due to the lower cost of raw materials and simpler manufacturing processes. However, when the added value of corrosion resistance and longevity is taken into account, stainless steel coils may prove to be a more economical choice in the long run, as they require less maintenance and replacement. In conclusion, steel coils and stainless steel coils have different properties and characteristics that make them suitable for specific applications. Stainless steel coils offer superior corrosion resistance, a shiny appearance, and higher tensile strength, while steel coils are more cost-effective. The choice between the two ultimately depends on the specific requirements of the application, such as the environment, aesthetics, strength, and budget.

- Q:im playing fallout 3 on ps3 and im at project purity. i keep dying and i heard about broken steel how or what is that plz help me out thnx.

- P.G.A/A. (Professional Gamer Advice/Answer) First off, what you need to know is Broken Steel is an expansion pack (to a certain extent). What you need to do is first download the content to the device that holds your Fallout 3 save files, be it PC or 360, and then you must simply complete Project Purity by choking to death... Or, if you have already done this and saved, then simply load up your game. You will know it's beginning when the old coot that leads the Brotherhood of Steel tells you that they have brought you Back from the dead. From there, you go on all sorts of wacky and explosion-filled adventures. There is even another segment with everyone's favorite patriotic technological warfare robot, Liberty Prime! And oh MAN is that part fun. As well, there are tons of new weapons, armors, and even the ability to (for a limited time) tame death-claws! But DO be careful, because they explode quite easily...there is also the Outcast Armor, which in my opinion is the most bad-*** because it is black armor with a red trim rather than a silver armor with a bluish-silver trim.

- Q:I want to know the special characters or the advantages of the corton steel. In what cases it is recommended to use?Thank you.

- *It is Corten steel.Grade A B. *Weathering steel, best-known under the trademark COR-TEN steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. United States Steel Corporation (USS) holds the registered trademark on the name COR-TEN. Although USS sold its discrete plate business to International Steel Group (now Arcelor-Mittal) in 2003, it still sells COR-TEN branded material in strip-mill plate and sheet forms. In some areas it may be known without the hyphen as Corten steel. The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheet. All alloys are in common production and use. It is a weather-resistant steel which is used in containers and hot flue gas line. The American Corten A Steel has a composition of C, 0.12; Si, 0.5; Cu, 0.5; Cr, 0.8; P, 0.1 and Mn, 0.5%. Although the tensile strength is less than 494 MPa the yield is in the region of 371 MPa. The combination of copper and phosphorus also increases the resistance to atmospheric corrosion which is important when thinner plates are used. The original steel A suffers a decrease in yield strength and notch ductility in thickness over 25 mm, to overcome which Corten B was developed-C 0.14; P 0.04; Mn 1.1; Cr 0.5; Cu 0.4; V 0.1; Bol Al 0.02. *COR-TEN A applies to plates up to 12.5mm in thickness, COR-TEN B applies to plates up to 50mm in thickness. *It has been used in bridge and other large structural applications such as the New River Gorge Bridge, the newer span of the Newburgh-Beacon Bridge, and the creation of the Australian Centre for Contemporary Art (ACCA). It is very widely used in marine transportation, in the construction of shipping containers.

- Q:Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q:What does "steel roll number" mean?

- According to the project schedule, track and coil encoding management to the quality of the products, which makes the production with a rational and quality after processing, troubleshoot save time, contribute to the automation of production smoothly, improve and stabilize the quality of products for production order arrangement and classification of coils.

- Q:y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- Peter Gunn Gave a good answer... Jason mentioned Stainless steel. Stainless steel should be avoided at all cost. Stainless steel is responsible for some really nasty injuries. It has a bad habit of shattering. It is a terrible steel for swords.

- Q:I also heard Stainless holds up better againts rust, blue steel needs more care.

- Blue Steel is definitely stronger than stainless. Le Tigre and Ferrari are too. However, nothing compares to the strength of 'Blue Steel' to a non-ambi-turner.

- Q:What is the role of steel coils in the production of conveyors?

- Steel coils play a crucial role in the production of conveyors as they are used to create the framework or structure of the conveyor belts. The coils are formed into a continuous loop, which provides strength, durability, and flexibility to the conveyor belts. Additionally, the steel coils ensure smooth movement and support heavy loads, making them essential components in conveyor manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords