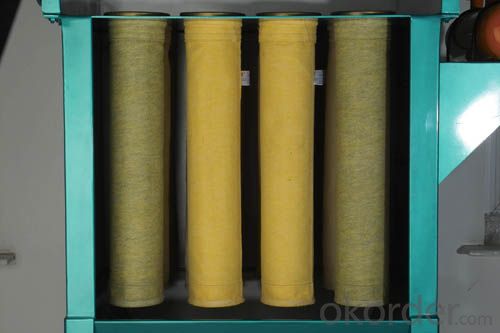

Polyimide Non Woven dust Bag Filters for power cement plant

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyimide Non Woven Bag Filters

Overview:

Our company can supple all kinds of Polyimide non woven bag filters.

Duo to the irregular cross section, the specific surface area of the fiber is relatively large, thus it has relatively good dust catching capability, its catching capability for ultra fine dust is higher than other fiber.

The quality of the filter bag determines the result of filtration to a great extent. Our company follows strict standards in sourcing raw materials and in the manufacturing process of all filter bags to ensure that they are 100% good quality. The polyimide fiber of tianyu filter bag is selected from world-famous enterprises

Application: cement, coal burning boiler, concrete mixing, waste incineration industry.

Features:

High tensile strength

High abrasive resistance

Easy for cleaning

High precision of filtration

Good air permeability

Good chemical corrosion resistance

Good thermal resistance

Long service life

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Specification:

Material | 100% Polyimide |

Weight | 550±30g/m2 |

Air Perm | 160-240L/m²S |

Warp Tensile Strength | >800N/5×500px |

Weft Tensile Strength | >800N/5×500px |

Warp Elongation | <35%< span=""> |

Weft Elongation | <45%< span=""> |

Continuous Temperature | 230℃ |

Surge Temperature | 250℃ |

Moist Temperature | 195℃ |

Finishing | Singed, smooth , stabilization |

Chemical Resistance: | Acid good |

Alkalis fair | |

Oxidizing Agents good |

Polyimide media may be attacked by moist heat hydrolysis, strong acids, or strong alkalis. The PTFE scrim enhances the media integrity in these conditions. To avoid such occurrences, please operate in an environment in according with the above recommendations.

- Q:What is the difference between the filtered water from the household water purifier and the VAT water purchased?

- Bottled water refers to the use of tap water or groundwater extraction, after the modern industrial technology (reverse osmosis and electrodialysis, distillation, resin softening) treatment from the pure water or mineral water, obtained by filling production line filling barrel products to PVC.

- Q:How to calculate the air volume required for industrial oil mist filters?

- regardless of the use of the nature of the liquid, air suction hood = volume *360 air inside the shell, wherein the cover shell of air volume = length * width * high -

- Q:What are the common types of industrial tap water filters?

- The accuracy of the filter in the filter belongs to an optimum filter, ammonia. When the liquid passes through a basket type mechanical filter, its dirt is collected by a basket of mechanical filters into the strainer, liquid ammonia, cryogenic material in the refrigeration, and a cylinder.

- Q:How to distinguish industrial cleaning agent?

- neutral industrial cleaning agent refers to the industrial cleaning agent whose pH value is about 7, such as neutral detergent WHC-1 and pH value of 7

- Q:What equipment is used for oil (cooling) in filtration equipment?

- The metal material used in industry, such as alloy steel and non-ferrous alloy, mostly by more than two yuan group, organization of these materials,

- Q:How to choose air filter

- Six, after-sales service: air filter failure, manufacturers need to buy change, so consumers should choose more perfect after-sales manufacturers, consumer products, or have a certain qualification of manufacturers

- Q:What kind of industrial products are there in electroplating factory?

- Wire electroplating and electroplating, filtration equipment, plating bath bar

- Q:Which manufacturers produce ceramic filters, the more comprehensive the better, the people throughout the country hooray!

- The other factory is relatively small.

- Q:What's the process of starting a mineral water company?

- business license industry and Commerce bureau

- Q:What about the cooling performance of industrial refrigerators?

- expansion valve through small or blocked. The refrigerant will reduce the amount of liquid, the evaporation temperature of the air conditioner is low, and the evaporator fin will be frosted, and the refrigerant will not evaporate. It will continue to evaporate into the air return pipe and compressor. 4

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyimide Non Woven dust Bag Filters for power cement plant

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords