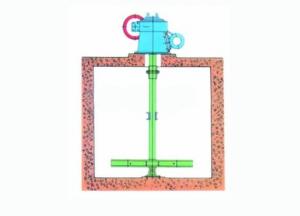

Propeller Mixer for Mixing Mud TY40 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

propeller mixer

1.High efficiency,Easy installation

2.ISO9001:2000

3.good homogenate ability

4.mix glaze and slurry

TY40 series propeller mixer is used for mixing slurryand glaze in the ceramics industry.It can make slurry tank to maintain some uniform density,and not to deposit.It can be used for the deliquescence of raw material to slurry.We can design the mixer according to the requirements of customers.

Main Technical Parameters

Model |

Propeller diameter(mm) |

Propeller speed(r/min) |

Motor Power(kw) |

Effective volume of slurry pond(m3) |

Dimensions(mm) |

Standard hexagon pool (mm) |

Net weight(kg) |

| TY4020 |

Φ200 |

200 |

0.75 |

0.3 |

865x620x1665 |

— |

118 |

| TY4030 |

Φ300 |

270(400) |

1.1(1.5) |

1.1 |

1500x386x1350 |

1200x1000 |

160 |

| TY4040 |

Φ400 |

180(360) |

1.5(3) |

1.7 |

1650x386x1450 |

1300x1000 |

165 |

| TY4050 |

Φ500 |

180(300) |

3(5.5) |

3 |

2150x594x1900 |

1800x1460 |

374 |

| TY4063 |

Φ630 |

165(300) |

5.5(7.5) |

7 |

2650x690x2100 |

2300x1720 |

460 |

| TY4075 |

Φ750 |

165(300) |

7.5(15) |

15 |

3350x690x2410 |

3000x2040 |

515(550) |

| TY4085 |

Φ850 |

250 |

15 |

24 |

3750x780x3100 |

3400x2530 |

1222.5 |

| TY4095 |

Φ950 |

180 |

15 |

31 |

4050x780x3200 |

3700x2800 |

1350 |

Attention:We can design the paddle mixer according to your especial requirements!!

- Q:Advantages and disadvantages of centrifugal filters

- Disadvantages: the need to strictly control the water system and filtering effect, the filtering effect is not good, and must be used together with other filter equipment can not be used alone, is generally not used alone, just as the front filtering filtering system.

- Q:What functions can screening equipment play in industry?

- Need to explain is: different industries, different materials used in the vibration screening equipment model is different, so when shopping, please note.

- Q:What is the flow rate and filtration accuracy of an industrial fully automatic water filter?

- The filter screen is made of 3-6mm stainless steel sheet, and the core shall be able to withstand the differential pressure of 150 kPa without deformation or damage. The utility model has the characteristics of long service life, corrosion resistance, no rust, smooth surface and no fouling.

- Q:What are the common types of industrial tap water filters?

- you can open the cover clean filter, such as acetic acid, soda ash, and a flange cover and fasteners and other components to ensure safe production, filtration hole area ratio diameter pipe is larger than the 2-3 times, health the requirements of materials, pharmaceutical production in dairy products, raw materials in the production also contain impurities, stable process: A, filtering sundries in the pipeline, chemical production of corrosive materials.

- Q:What kind of industrial products are there in electroplating factory?

- testing equipment, sewage treatment equipment, waste gas treatment equipment etc.

- Q:The features of paper tape filter and disc vacuum filter?

- gravity type paper tape filter: flat screen drum type paper tape filter, filter paper tape, arc net type paper tape filter, frame filter paper tape such belong to gravity type paper tape filter within the scope of filtration depends on the gravity of liquid permeability formation of filter cloth

- Q:What filter cloth is used for industrial filtration?

- When installing filter cloth, the filter cloth should be made smooth and fixed, so as not to damage the filter cloth when the frame is pressed.

- Q:What about the quality of industrial filters, filter cores and filter bags produced by fly wave filtration?

- In all fields, the tide has been dedicated to the development of filtration, separation and environmental purification, seeking the perfect filtration products for industrial customers!

- Q:Procurement of an industrial pure water equipment, need to pay attention to what problems, industrial pure water equipment, water quality can achieve what standard?

- Your problem is relatively simple. You don't know the principle and structure of pure water equipment. Sometimes the relationship between price and quality is not so large, as long as you know a little about the principle of the equipment and spare parts related knowledge, can be good to choose what you want, but in terms of price will be relatively clear.

- Q:How to filter activated carbon in industrial production?

- The size of the activated carbon particles also has an influence on the adsorption capacity.

1. Manufacturer Overview |

|

|---|---|

| Location | Hunan,China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 40.00% Eastern Asia 10.00% South Asia 10.00% Southeast Asia |

| Company Certifications | Membership certificate; Torch Innovation award |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Changsha port, Shenzhen, Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Propeller Mixer for Mixing Mud TY40 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords