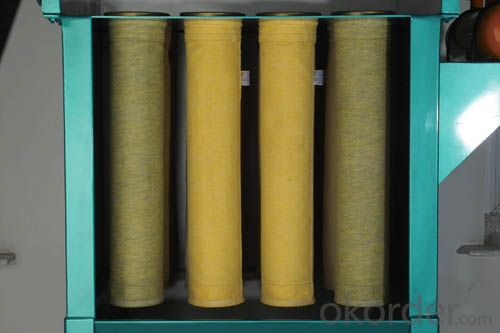

Cement dust filter bags made of needle felt

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cement industry-High temperature and corrosion resistance filter media

In the cement industry, our main products are polyimide series bag filters, aramid series bag filters, polyester series bag filters, glassfiber woven bag filters, MTS bag filters, which are used in many large cement plants in

We use different treatment according to the specific conditions of cement kiln

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Dust Filter Bags Used For Cement Kiln

Abrasive dust, high gas temperatures and aggressive gas composition are the most important points to be considered for the selection of a suitable filter medium. Continuous high temperature combined with active gas composition will cause the chemical corrosion of the filter material gradually. It is a big problem to avoid the hydrolysis and oxidation. We choose to use polyimide fiber made filter material.

Polyimide fiber can stand temperature from 220 to 260.and it has good resistance hydrolysis, oxidation and acids. It has irregular fiber cross section which is advantageous under aspects of dust filtration

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

- Q:What are the famous water treatment plants in China?

- Water used in chemical industry, chemical reaction cooling, chemical agent, chemical fertilizer and fine chemical industry, cosmetics manufacturing process, water system.

- Q:What is an industrial oil mist collector?

- In some machining center or machine tool factory, due to some mechanical acceleration will splash some particles, and because of the high-speed operation have great heat, so some manufacturers will add some refrigerant or emulsion, there will also be a refrigerant or emulsion is splashed out in the process of adding.

- Q:What functions can screening equipment play in industry?

- filtering, cleaning materials, simple is the impurities in the material will remove or substandard products to ensure the quality of products.

- Q:Is the salt used for water purifier the industrial salt?

- The cation resin used in pure water equipment is the softening action of water. When the ion reaches the saturation state, the salt water is the regeneration of the ion, and the industrial salt is generally used.

- Q:What equipment is used for oil (cooling) in filtration equipment?

- adding the third element in the two yuan in the alloy, will change the solubility of the original alloy component, or even a new phase of the new generation phase transition.

- Q:What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- The best one to find out, write specifications,

- Q:What's the process of starting a mineral water company?

- Second, the above pre application for approval, you can apply for the following documents:

- Q:Can industrial oil mist filter be discharged indoors directly?

- According to the international standard as filtration precision accuracy of PM2.5 (5um) can reach 95% to 99.95%, can be directly discharged to the interior

- Q:What kind of filtration equipment do you use to treat wastewater?

- ion exchange method. (7) biological treatment technologies include biological flocculation, biological adsorption, biochemical methods and phytoremediation.

- Q:Application range of quartz sand filter

- Also used in the water reuse system, swimming pool, circulating water treatment system depth filtration. It also has good removal effect for suspended solids in industrial wastewater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cement dust filter bags made of needle felt

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches