Wet High Gradient Electro Magnetic Separator Liquid Form

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

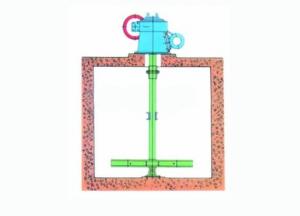

electro magnetic separator

1.convenient operation, easy maintenance

2.Convenient cleaning,save time

3.ISO9001:2000

4.wet

Features:

Our electromagnet is called a ferromagnetic-core or metal core electromagnet, Inside our electromagnet machine, we install many metal wires side by side like a coil.

This coil forming the shape of a straight tube, a helix (similar to a corkscrew) is called asolenoid when the electric current goes through this corkscrew brings the magnetic filed which pass onto the magnetic screen. When the slurry pumped into the machine pass through this magnetic screen from the bottom inlet, these ferrous materials will be attracted by this magnetic screen.

-Lower energy consumption, high magnetic field gradient, well-proportioned magnetic fields, and better iron removal result.

-Full-automatic unwanted-iron discharge and clean system.

-Timing for discharge and clean process can be adjusted according to different situation.

-It uses vibration motor together with high-pressure water pump for unwanted-iron discharge, thus make the remove more clean and easier.

-The brake valve is using imported materials; there is no leaking, better wearable, lower air consumption.

-The magnetic media screen is using high performance stainless steel; the highest magnetic field is

up to more than 20000 gauss. It is easy to discharge the unwanted-iron materials just by switch off the power.

Main Technical Parameters

Model | NCXZ190 | NCXZ250 |

| Working Caliber (mm) | 190 | 250 |

| Excitation power (kw) | 1.5 | 3 |

| Flux peak (T) | 2.0 | 3 |

| Excitation voltage (V) | 90-110 | 175-200 |

Capacity (t/h) | 5-10 | 10-25 |

| Selected Particle size(mesh) | 60-400 | 60-400 |

| Raw material iron content(%) | ≤1.0 | ≤1.0 |

| De-iron rate (%) | ≥90 | ≥90 |

| Winding temperature rise(°c) | ≤70 | ≤70 |

| work time | Periodicity | Periodicity |

| Insulation Class | E | E |

| Net weight (kg) | 1000 | 1800 |

- Q:The reason for the great pressure difference of the mechanical filter

- power generation, chemical, paper, beverage and other raw water pre filtration treatment.

- Q:Could you tell me how to make the filter, and mine is also very delicious and urgent. Thank you

- he smell is mainly activated carbon filtration, but before it to filter out dust or activated carbon will soon be buried on the dust.. by two or three layers, a layer of coarse filter with acrylic foam

- Q:What material is an antiseptic filter? Is there a detailed introduction?

- weak corrosive materials in chemical, petroleum production and urban heating. Such as water, ammonia, oil, hydrocarbons and so on

- Q:How to calculate the air volume required for industrial oil mist filters?

- Volume internal components (such as rotary turret occupied the above method is only suitable for the volume), the industry decided to Bodie oil mist filter specifications oil mist filter other refer to different manufacturers standard.

- Q:What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- , models, sizes, brands, if not listed on what brand equipment,

- Q:Price of water purifier in China Aviation Industry

- You may never have thought: water purifier manufacturers produce the same brand, different models, different price of water purifiers, whether there is a problem

- Q:How is recrystallization done in industry?

- Before the best feeding, according to the volume of the kettle and the loading factor, the material is well calculated and put into use. Of course, fear of solvent multi throw, before debugging can be appropriate less points, not enough to fill, with a pump, the loss is very small..

- Q:The features of paper tape filter and disc vacuum filter?

- The filter has a general filtration rate of 50L/min-2000L/min, and the filtration accuracy is about 15-20 microns. The unit occupies a small area, and is suitable for single machine filtration, such as cold rolling liquid filtration system.

- Q:How to filter activated carbon in industrial production?

- The adsorption principle of activated carbon is to form a balanced surface concentration on its particle surface.

- Q:How about water treatment equipment, water treatment equipment?

- Sewage treatment equipment using the membrane bioreactor technology is a new technology of biological treatment technology combined with membrane separation technology, replacing the traditional process in two sedimentation tank, it can efficiently carry out solid-liquid separation, direct

1. Manufacturer Overview |

|

|---|---|

| Location | Hunan,China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 40.00% Eastern Asia 10.00% South Asia 10.00% Southeast Asia |

| Company Certifications | Membership certificate; Torch Innovation award |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Changsha port, Shenzhen, Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wet High Gradient Electro Magnetic Separator Liquid Form

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords