Pneumatic Double Flange Butterfly Valve,Ductile Iron Wafer Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

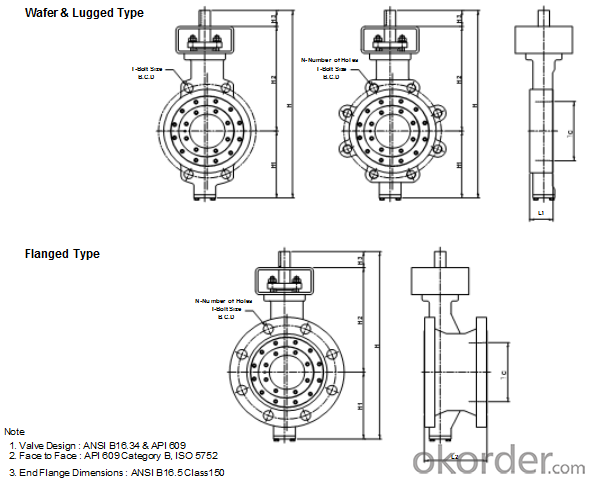

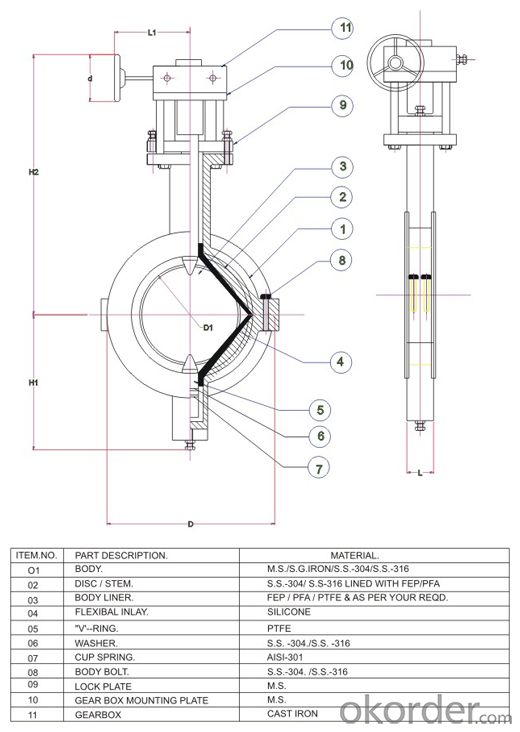

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What is called protective valve, and other valves what is the difference?

- Protection valve should be in the air defense valve, can be copper gate valve. (according to the specific use of civil air defense requirements, design institute does not count).2, while the protection valve should be a locking device with the valve, not the general valve can be replaced.

- Q:What does the valve stroke mean?

- The distance from one position to another. Usually in the first position of the cut position, the second position is put through the position. Unless the valve has 3 positions.[1] to determine the stroke of the valve is the valve and valve two, closing stroke of its opening height, the valve opening height to diameter of the valve is fully open, 1/3, so the opening height is part size below the path + gate is closed.[2] valve: valve (Famen) is a fluid conveying system control components, with a cut-off, regulation, diversion, to prevent reverse flow, voltage regulation, shunt or overflow, pressure relief and other functions. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:Ketem valve relative to other valve companies in the industry what are the advantages?

- Floating seal: electric drive, electric ball valve flange connection floating ball straight, seal form with seal, the sealing surface of the valve seat material for hard alloy, nominal pressure PN16~PN63, nominal size DN15~DN200, suitable temperature of -28~500, the valve body is made of carbon steel or stainless steel. As a result of the use of hard sealing (metal seal), this valve is particularly suitable for particles, solids, slurry and other medium and high temperature and high pressure pipelines.

- Q:I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- I was about 08 years of contact valve, indeed many, but a company, all products will not have, are designed to do certain types of valves, such as for HVAC, or petrochemical, some other valves used in engineering, will do the purchase, so you only according to the company's products study on the line, need to learn what, what, high efficiency.If you do the design, you have to learn a lot of things: "mechanical design manual" and "valve design manual" is essential, often used;Of course, functional things are the basis, that is, the structure, the work principle must be obtained first, in order to do relevant design and improvement;First of all, the structure design, CAD must learn, three-dimensional software also have to learn one, Solidworks, Peo/E, UG, Catia can be;Second, strength analysis is necessary, so in mathematics, mechanics, mechanical design things to learn solid; can make strength analysis with finite element analysis software, need to learn, software Comosworks, Ansys;Third, the valve design will have fluid aspects, flow design, flow capacity, flow characteristics of the study, to study fluid mechanics, heat transfer, etc., CFD software has Fluent, Ansys, CFX, Star-CD;In addition, materials and technical aspects should be learned.Slowly, I also step by step by side with coming.Hope to be of help to you.

- Q:How to check the quality of the valve?

- First of all, to check the appearance of the valve is smooth and smooth. Cast valves without sand holes and obvious flaws. Forged valves check nominal pressure or pound level.Second, check the material of the valve, that is, the material composition, this is very important, the material does not meet the standard on the device will be a big problem.Finally, check that the switch is sensitive and the signs are clear. Test pressure is the last step.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:Who knows which kind of water valve is good?

- Classification of domestic valves:pipeline valveBathroom valves, kitchen valves, etc faucetsPipeline valve is generally sealed with rubber valve is better, rubber sealed valve sealing performance is very good and durable;Bathroom valves, kitchen valves and other faucets will use copper into the Dian valve, copper valve is not rusty, durable. ,Hope to help you.

- Q:What are the other valves used for the control of dual-use items?

- That is to say, your valve needs to be used as dual-use items and technology import and export licenses. Shanghai import and export can find me. We have electronic keys for dual-use items

- Q:Is the heat jacketed valve fitted with flanged flanges?

- Insulation valve is the standard valve, just in order to ensure the link bolt flange to super space, usually a large ball than normal level, such as the use of the path is DN80 flange, flange is DN100, so is the standard, but the size of flange connecting with other valves are not the same.

- Q:What is the use of each brand in the super high-rise, commercial complex, hotel? Price comparison of each brand? In the general valve, balance valve, electric valve, who did the best? Any knowledge about the valve, please ~ ~ thank you for your generous with your criticism

- Watts is the origin of industrial water valve, after so many years of development, the current air-conditioning, water supply and drainage, fire, general valve Liwoci is most commonly used, compared with the best foreign brands.

- Q:Valve legend

- F means the initial letter of the valve, which is shown as a stop valve

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pneumatic Double Flange Butterfly Valve,Ductile Iron Wafer Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords