Plastic Flower Propagator Seed Tray and Lid for Greenhouse

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features:

Material: HIPS

Thickness: 0.5mm-1.5mm, Standard:1mm

Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

Standard:540mmX280mm

Cell count: 18-512

Package: In Carton

Warrenty: 8-10 times

Picture:

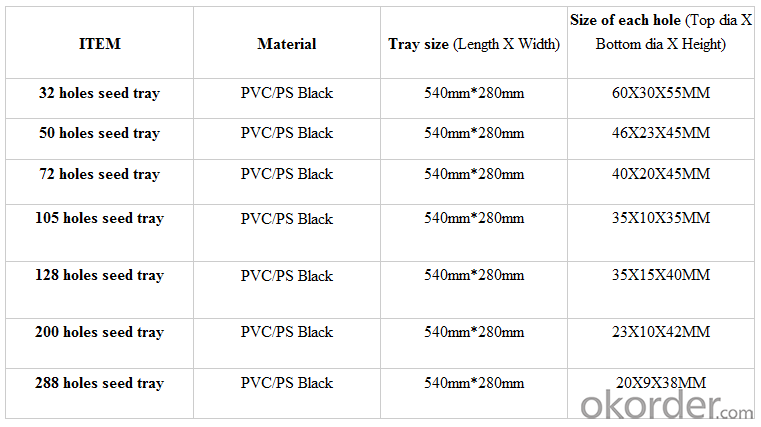

Specification:

FAQ:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 55cm*29cm*50cm.

- Q:How do agricultural plastic products help in pest control?

- Agricultural plastic products help in pest control by providing a physical barrier that prevents pests from damaging crops. For example, plastic mulches or covers can be used to cover the soil, preventing weed growth and reducing the habitat for pests. Additionally, plastic films can be used to create a greenhouse environment, protecting plants from pests and creating optimal growing conditions. Overall, agricultural plastic products play a crucial role in minimizing pest infestations and protecting crops, leading to higher yields and improved agricultural productivity.

- Q:What is the best ground cover for a tropical garden?

- One of the best ground covers for a tropical garden is the Asian jasmine (Trachelospermum asiaticum). It is a low-growing, evergreen vine that forms a dense carpet of glossy, dark green foliage. This ground cover is perfect for suppressing weeds, preventing erosion, and adding a lush, tropical look to your garden.

- Q:What are some ground cover options for acidic soils?

- Some ground cover options for acidic soils include creeping juniper, heather, blueberry bushes, and ferns.

- Q:Are there any industry standards for agricultural plastic products?

- Yes, there are industry standards for agricultural plastic products. These standards are designed to ensure the quality, safety, and environmental sustainability of these products. They cover various aspects, including materials used, manufacturing processes, labeling, and disposal methods. Compliance with these standards is essential for manufacturers and suppliers to meet the requirements of the agricultural industry and to provide customers with reliable and sustainable plastic products.

- Q:well my mother seys that it is and i dont think so , so in order for us to stop fighting i need to know the truthso is burned plastic toxic??

- This Site Might Help You. RE: is burned plastic toxic? well my mother seys that it is and i dont think so , so in order for us to stop fighting i need to know the truth so is burned plastic toxic?

- Q:Before we had plastic in our homes...whether it be in Victorian England or Colonial Williamsburg, everything had such a nice feel to it. Now with plastic everywhere though, everything is ugly and depressing. Why don't we abolish plastic?

- complicated aspect. try searching on to google and yahoo. it can assist!

- Q:How do you prevent ground cover plants from spreading too much?

- There are a few ways to prevent ground cover plants from spreading too much. Firstly, regular pruning or trimming can help control their growth and prevent them from becoming too invasive. Secondly, creating physical barriers like edging or installing root barriers can restrict their spread. Lastly, regularly monitoring and removing any unwanted runners or shoots can help maintain the desired size and prevent excessive spreading.

- Q:What are the different types of agricultural plastic covers for hay and silage?

- There are several different types of agricultural plastic covers for hay and silage, including bale wrap, silage bags, and bunker covers. Bale wrap is a stretchable plastic film that is used to tightly encase individual hay or silage bales, protecting them from moisture and preserving the quality of the forage. Silage bags are large plastic tubes that are filled with chopped forage and sealed to create an airtight environment for fermentation. Bunker covers are heavy-duty plastic sheets that are used to cover large stacks or piles of hay or silage, providing protection from the elements and helping to maintain the nutritional value of the stored forage.

- Q:Can nursery trays be used for orchid propagation?

- Yes, nursery trays can be used for orchid propagation. They provide a suitable and convenient container for starting orchid seeds or propagating orchid cuttings. Nursery trays allow for proper drainage and provide a controlled environment for the young orchids to develop and grow.

- Q:What are some ground cover plants that provide fragrant foliage or flowers?

- Some ground cover plants that provide fragrant foliage or flowers include lavender, thyme, sweet woodruff, creeping thyme, creeping phlox, and sweet alyssum.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Flower Propagator Seed Tray and Lid for Greenhouse

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords