Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black masterbatch is made of high tinting strength carbon black and virgin pe resin and additives production

Additive amount:2%-30% is recommended. Or adjust the dosage as per your products performance

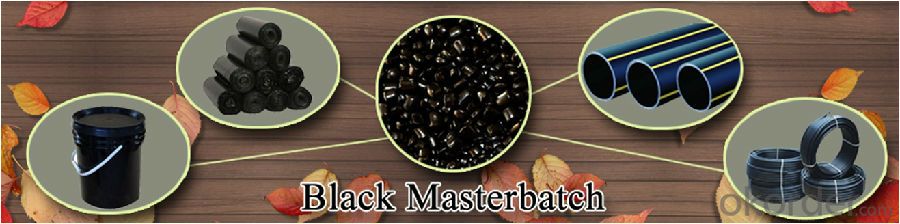

Application:Blowing film,injection molding,pipe and wire drawing

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Advantage of Black Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Black Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of Black Masterbatch

- Q:What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q:What is plastic film material?

- The material is plastic particles. Polyethylene film is used for polyethylene particles; polypropylene film is polypropylene particles. Some of the films are blown out of film blowing machines; some are cast films and pressed out of the machine.

- Q:What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q:What is the difference between EPS plastic particles and PS? What materials are represented?

- PS does not have no foaming agent. It is divided into GPPS (ordinary type) and HIPS (impact type). It is used for injection molding, extrusion, television, telephone shell, cup and so on.The main ingredients are polystyrene.

- Q:What material is the disc made of, metal or plastic?

- The compact disk is the carrier of functional structures (such as grooves, etc.), and its material is polycarbonate (PC), which has excellent impact toughness, large temperature range, good dimensional stability, weatherability and non toxicity.

- Q:What are the main biodegradable plastic bags made of?

- Biodegradable plastics(1) natural polymer modification method. Starch, cellulose, chitin, lignin, seaweed and other natural polymers as raw materials, through chemical modification and copolymerization method, these molecules were modified to synthesize biodegradable plastics.(2) chemical synthesis. The simulation of natural polymer structure, starting from simple water molecules, in the polymer chain of plastic with active groups such as amide, peptidyl, ester compounds containing these radicals, similar to natural protein structure, fragments of grease, easily biodegradable.(3) microbial fermentation, many microorganisms can take some organic substances as carbon source, through metabolism, secrete, produce polyester polymer, these molecules are easy to degrade, and can be further recycled.

- Q:Plastic raw materials are granular, why not powder?

- Like PP and PVC, they all have powder. Only powdery materials are liable to cause dust poisoning. In fact, the powder material in the performance of granular to better, but in the processing of molding difficult.

- Q:What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- 1. recycled material is not natural (ABS is yellow).2. non black pellets with black spots are recycled.3. the impurity in the aggregate is the recycled material.4. of the voids in the pellets are recycled.5. do MFI test, the result is more than 10% of indicators are recycled material.6., feed heating, smell, smoke, melting temperature is low, fast flow is recycled material.

- Q:What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- High density polyethylene (LDPE) transparency, the equivalent number can reach about 90%, but the temperature should be controlled well, there is no general problem, that is, the cost is higher than other products

- Q:What raw materials do plastic color printing plants use?

- Mainly plastic film and ink, the film is generally in accordance with the nature and requirements of products such as PVC film, POF film

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords