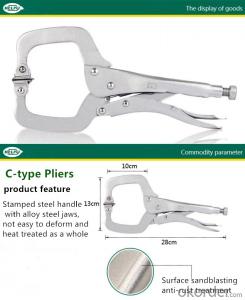

Plastic Bags Aluminum Alloy Small Square Saw Frame SJ-0136

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Adjustable saw frame:8"/10"/12",

surface treadment:chrome plating, plastic spraying, corrosion resistance,with non-slip handle.

Saw blade:18TPI,carbon steel product whole steel structure, with non-slip handle. Can cut steel, wood, plastic stool rod type, durable

Our Services

1.Well-trained and experienced staffs to answer your enquirers within 24hrs.

2.OEM&ODM or customized tools are available.

3.We have strict test and QC system to guarantee the high quality.

4.Track the order until you get the goods.

We can supply the sampe for inspect,but the sample cost and freight paid by customers

We have a special team for oversea marketing service,if there is any query,please feel free to contact with us.

FAQ

If you have any question, Please feel free to ask us.

- Q:Why do I bench sawing, cutting the total to the left.

- Sawing frequency should also be grasped, should not be too fast, one minute 40-60 times.Cut the thread before sawing. The workpiece is clamped on the left side of the table vise and can not be extended too long.

- Q:Why is the saw toothed?

- If the blade stagger, sawing wood, saw the road is very wide, not only pulled back and forth more effort, and can reduce friction and prolong the life of the saw. Have experience in carpentry, know to saw round things, should use the saw blade is narrow, toothed tilt angle larger saw. Because staggered sawtooth the larger the angle, the kerf is large, it can be very flexible to let the saw along the circle line pull. So saw arc bending or irregular things, suitable serrated stagger angles larger saw. The size of the gradient staggered sawtooth, called "saw how much".

- Q:What are the advantages and disadvantages of sawing machine sawing and multi piece?

- The disadvantage of "multi blade saw" is the higher requirement of the saw blade. Whenever the use of the multi chip saw General requirements of timber, saw, saw blade thin, high degree of finish. Because of too many teeth of the saw blade, sawdust not easy to discharge from the equipment, will cause the local temperature is too high, easy to burn tablets. For example, the saw is a shaving board, and the shaving board is too rough, too much impurities, too much resistance, will burn.

- Q:How do we see the plaster line?

- Crossed. Put the plaster line in the slot, play it on the mouth, and see the plaster line as a 45 degree bevel. The saw will change direction. See the one, the two 45 degrees and the angle of 90 degrees

- Q:What brand of gasoline (petrol saws, felling saw) better? How much is the price?

- The best brand is Yamaha, quality really did not have to say, is a little expensive, hope to adopt

- Q:How to use wood cutting machine to cut 45 degrees angle and 45 degrees of yin and yang angle?

- 45 degree angle refers to the angle of the wall is Yin / other buildings two concave angle and a 90 degree angle

- Q:Tara Rhea do wood sawing machine

- First of all, you must have a work table for a wood sawing machine. The workbench, needless to say, is the first major piece synthesized by a player". The table is very simple to make and ten pieces of wood will do.

- Q:What kind of hand saw?

- Gardener: saws, folding saws.3, fitter: iron bow.4, the hand-held machine power saw: portable chain saw, electric saw.

- Q:The circular saw is very difficult and still smoking when cutting wood. What's the matter?

- You change a saw blade, try it, maybe the saw blade is flat, and when you cut the thick wood, the friction is too big.

- Q:Is the saw used by the fireman a cutting saw?

- A chain saw powered by gasoline engines, used primarily for cutting and making material. Its work is done by cutting the crosswise movement of an interlaced L blade across a saw chain.Chain saw is a kind of broken and broken equipment. It can be divided into motor chain saw, non motor chain saw, concrete chain saw and so on according to function and drive mode.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Bags Aluminum Alloy Small Square Saw Frame SJ-0136

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords