Mullite corundum brick for glass furnace top

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fused Cast Brick

CMAX fused cast AZS (alumina, zirconia and silica) firebricks are mainly categorized into 33#, 36# and 41# according to different zirconia's contents from 33% to 41%.

Feature of Fused Cast Brick

High refractoriness

Excellent resistance to corrosion of molten glass

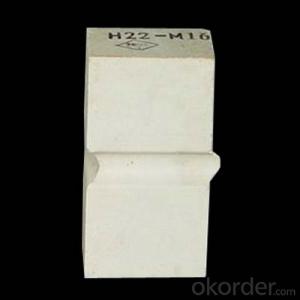

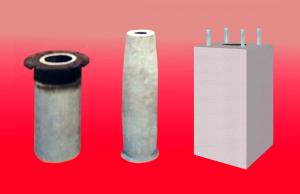

Image of Fused Cast Brick

Technical Data of Fused Cast Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q:How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q:What are the refractory materials?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q:How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q:Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q:What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q:Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q:What are the main constituents of refractory bricks?

- Brick, refractory brick is containing more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q:What refractory materials are used in industrial furnaces?

- The working conditions of industrial furnaces should first be investigated thoroughly, and the primary and non essential factors affecting the construction of furnace materials shall be analyzed. Focus on thinking, the temperature change condition, temperature bump slag properties, furnace atmosphere, heat insulation, impact wear and other special requirements, to ensure the quality of the life and product.

- Q:How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mullite corundum brick for glass furnace top

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products