Low Impurity High alumina calcined bauxite in bulk

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Impurity High alumina calcined bauxite in bulk

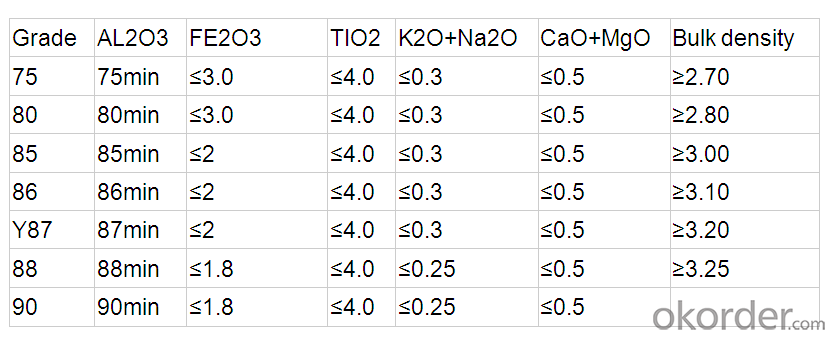

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

High grade calcined bauxite used for raw material of kinds of refractory products and monolithic series.

Usage

Calcined Bauxite used in

1.aluminium metallurgy,

2 refractory material,

3 precision casting,

4 aluminate cement

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:What kinds of fireproof materials does the safe use?

- The fireproof materials of the safe, cement foam. It is often said recently that the safes with cement inside are bad. Actually, it is not like this. Chemical means are taken to make the cement inside safes rise like a leaven dough so as to achieve good insulation. The principle is the cement foam. Fireproof safes with such techniques have good performance in terms of fireproofing and anti-theft. The manufacturing processes of this fireproof safe are highly technical, some safes with poor techniques have problems in quality. Here are some data of the foam cement.

- Q:which kind of material should be used in fireproofing cabinet?

- Natural stone,marble. advantage: Colorful, soft texure, natural and diverse texture, easy to cut or engraving molding. Disadvantages: Because it is a natural formation, tiny loose crackle is easily folded, because the stone is porous material structure, if sewage and waste water permeate in the structure in the process of production, transportation or construction, it's difficult to clean and easy to crack. In daily cleaning, it is inevitable that there will be some residue left, and dirt is filled into crack under the wiping of rag and becomes a breeding ground for bacteria. 2, granite. advantages: Granite has big density and high hardness, with wear-resistant surface, it's one of the most common materials for family decoration. Compared with natural marble, it can be used in the materials of kitchen countertops, and granite has good anti-bacterial regeneration ability. Disadvantages: As the cabinet table material, natural stone is usually not very long, so in order to produce a long overall table (especially U-shaped, L-type table), it will certainly exist joints, which are also easy to hide dirt. 3, artificial stone. advantages: Artificial stone has richful lines and colors, and it can be comparable to stone, it's non-toxic, non-radioactive, easy to clean, and can be truly seamless splicing. it belongs to economic environmentally friendly material. Disadvantages: Artificial stone belongs to the processing industry, and has low technology requirements, The inferior products of many small companys are fulled in the market and damage customers' interests. There exist faded color,poor aging resistance,oil stain and other issues in affordable products.

- Q:Can anyone tell me what is a high alumina refractory?

- Refractories refer to a class of inorganic non-metallic materials whose refractoriness are no less than 1580 ℃. Refractoriness is the Celsius temperature when cone-shaped samples can resist high temperature without softening and melting down in the absence of a load. But it is not accurate to define refractory merely by judging that whether the refractoriness is no less than 1580 ℃. Currently, the materials whose physical and chemical properties allow them to be used in high temperature environments are called refractories. Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and so on, among which the metallurgical industry is the largest demander in this regard, accounting for 50% to 60% of total output. Hope it will help you out!

- Q:Does anyone know about the A-level fireproof materials?

- rock wool external wall composite board, A1-level fire rock wool board, hidden slit rock wool board ? 30, A1-level fireproof mineral wool sound-absorbing board. What about the sound-absorbing sheet? glass fiber acoustic board engineering of the TV backdrop ? 85, A1-level fireproofing and thermal insulation rock wool board is hydrophobic thermal insulation, external wall thermal insulation materials ? 200, high temperature resistant calcium silicate board, LCFC/calcium?silicate?board is A1-level fireproof materials with high-quality and low-price ? 75, the prices above are from the internet for reference only, and the purchase prices vary according to the market.

- Q:Who knows the refractoriness of high temperature lightweight firebricks?

- Hefei Jiu oak decor help you answer; the biggest feature is refractory: refractoriness 700.

- Q:Where is the development of refractory industry?

- The rapid development of continuous casting technology of its related @ China @4 honing refractories develop and increase in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

- Q:Do you know where I can buy refractories?

- You can buy refractories in these places: 1. Addresses of refractory factory: No. 57, Qingshan District, Wuhan 2. Address of Qingshan refractory factory in Wuhan: Special NO.1 Xingli Road Hongshan District, Wuhan 3. Address of Xinghuo refractory factory in Hongshan district: No. 34 Qingshan District, Wuhan 4. Address of Henao refractory factory: No. 78 Jiangxia District, Wuhan

- Q:Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q:Does anyone know the fire endurance of steel stud partition?

- Indeed ① Dragon Brand gypsum board fire-resistant partition: Its fireproofing extreme time is 4 hours, suitable for firewalls of a variety of public buildings, public exit passageway and other partitions, which meets the first level of fire protection standard ② fireproofing and pressure-resistant partition: Refers to the partition which can withstand momentary gas shocks of over 1200pa , mianly used for the room partition with inert gas fire-fighting needs, such as equipment rooms. The pressure-resistant degree of fireproofing and pressure-resistant partition of Beixin Building Materials can be up to 4800Pa, especially suitable for high-rise fireproofing.

- Q:how to classify Insulating Refractory ?

- General materials have test reports, where fire rating is labled.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Impurity High alumina calcined bauxite in bulk

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords