All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

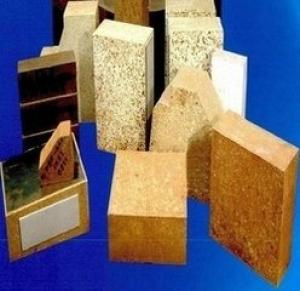

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the disadvantages of using refractory coatings?

There are several disadvantages of using refractory coatings. Firstly, they can be quite expensive to purchase and apply. Additionally, these coatings require specialized equipment and skilled technicians for installation, which further adds to the cost. Another disadvantage is that refractory coatings have limited durability and may require frequent reapplication, particularly in high-temperature environments. Furthermore, these coatings can be brittle and prone to cracking or chipping, leading to reduced effectiveness in protecting the underlying material. Lastly, some refractory coatings contain hazardous materials, which can pose health and safety risks during application and potentially release harmful substances when exposed to extreme temperatures.

What are the advantages of using refractory coatings for erosion resistance?

Refractory coatings offer several advantages for erosion resistance. Firstly, they provide a protective barrier that prevents the erosion of underlying materials by abrasive particles or high-velocity fluids. This helps to extend the lifespan and durability of components, reducing the need for frequent repairs or replacements. Additionally, refractory coatings can enhance the overall performance of equipment by reducing friction, improving efficiency, and minimizing energy losses. Moreover, these coatings can withstand extreme temperatures and chemical environments, making them suitable for a wide range of industries. Overall, the use of refractory coatings for erosion resistance can significantly enhance the longevity and functionality of various equipment and structures.

What are the different types of refractory insulation materials?

There are several types of refractory insulation materials, including ceramic fiber, insulating fire bricks, vermiculite, perlite, and calcium silicate.

Wholesale Refractory Materials from supplier in Thailand

We understand the importance of timely delivery and competitive pricing, and our procurement services are tailored to meet your specific requirements. With our strong network and partnerships with top manufacturers and suppliers, we can source and deliver the best quality Refractory Materials to your doorstep.

Our team of experienced professionals is committed to providing excellent customer service and technical support. We have a deep understanding of the local market and can offer valuable insights and solutions for your projects. Whether you need assistance with product selection, technical specifications, or installation guidance, our experts are here to help.

At CNBM Thailand, we pride ourselves on our commitment to quality. All our Refractory Materials undergo rigorous testing and meet the highest industry standards. We work closely with our suppliers to ensure that our products are of the highest quality and provide optimal performance in various applications.

We value long-term partnerships and strive to build strong relationships with our customers. Our customer-centric approach means that we prioritize your satisfaction and aim to exceed your expectations. We believe in open communication, transparency, and integrity in all our dealings.

Choose CNBM Thailand as your trusted supplier for Refractory Materials in Thailand. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

Our team of experienced professionals is committed to providing excellent customer service and technical support. We have a deep understanding of the local market and can offer valuable insights and solutions for your projects. Whether you need assistance with product selection, technical specifications, or installation guidance, our experts are here to help.

At CNBM Thailand, we pride ourselves on our commitment to quality. All our Refractory Materials undergo rigorous testing and meet the highest industry standards. We work closely with our suppliers to ensure that our products are of the highest quality and provide optimal performance in various applications.

We value long-term partnerships and strive to build strong relationships with our customers. Our customer-centric approach means that we prioritize your satisfaction and aim to exceed your expectations. We believe in open communication, transparency, and integrity in all our dealings.

Choose CNBM Thailand as your trusted supplier for Refractory Materials in Thailand. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

Hot Search

- Monolithic Refractories in Kyrgyzstan

- Ceramic Fiber Products in Montenegro

- Refractory Bricks in Botswana

- Raw Materials For Refractory in Bahrain

- Refractory Bricks in Cambodia

- Monolithic Refractories in Thailand

- Raw Materials For Refractory in Djibouti

- Refractory Bricks in Tanzania

- Ceramic Fiber Products in Tonga

- Refractory Bricks in Indonesia