All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is cold-rolled steel used in the production of military and defense equipment?

Cold-rolled steel is widely used in the production of military and defense equipment due to its unique properties. The cold-rolling process enhances the strength, durability, and toughness of the steel, making it ideal for manufacturing various military components and structures. It is commonly utilized in the production of armored vehicles, tanks, aircraft carriers, submarines, and other defense-related structures. Cold-rolled steel provides superior protection against ballistic threats, improves structural integrity, and allows for efficient fabrication of complex shapes and designs required in military equipment.

How does cold-rolled steel perform in cryogenic and low-temperature applications?

Cold-rolled steel performs well in cryogenic and low-temperature applications due to its excellent strength, toughness, and ductility characteristics. It maintains its structural integrity even at extremely low temperatures, making it suitable for use in industries such as aerospace, automotive, and energy where exposure to cryogenic conditions is common. Additionally, the cold-rolling process enhances its surface finish and dimensional accuracy, ensuring optimal performance in these demanding environments.

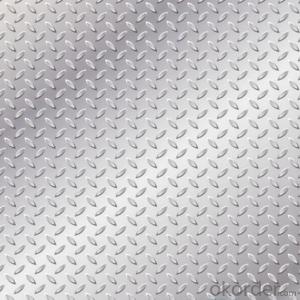

What are the surface finish options for cold-rolled steel, and how do they impact aesthetics and functionality?

Some common surface finish options for cold-rolled steel include mill finish, brushed finish, and powder coating. Mill finish is the default option and provides a smooth, shiny surface. Brushed finish involves creating parallel lines on the surface, giving a textured appearance. Powder coating involves applying a layer of powdered paint, which is then cured to form a durable and visually appealing finish.

The chosen surface finish can greatly impact both the aesthetics and functionality of cold-rolled steel. A mill finish can enhance the sleek and polished appearance, making it suitable for applications where a clean and professional look is desired. On the other hand, a brushed finish adds texture and can help hide scratches or imperfections, making it more suitable for applications where durability is a priority.

In terms of functionality, the surface finish can also affect the steel's resistance to corrosion and wear. Powder coating, for instance, provides an additional layer of protection against environmental factors, enhancing the steel's durability and making it more resistant to chipping, fading, and rusting. This makes it ideal for outdoor applications or areas with high exposure to moisture or chemicals.

Ultimately, the choice of surface finish for cold-rolled steel depends on the desired visual appeal, level of durability required, and the specific application or environment in which it will be used.

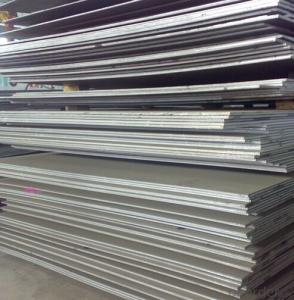

What are the advantages of using cold-rolled steel in manufacturing?

There are several advantages of using cold-rolled steel in manufacturing. Firstly, cold-rolled steel has a smoother surface finish compared to hot-rolled steel, which enhances its aesthetic appeal and makes it more suitable for applications requiring a polished appearance. Secondly, cold-rolled steel is known for its higher strength and hardness, making it ideal for manufacturing durable products that need to withstand heavy loads or impact. Additionally, the process of cold rolling helps to improve the dimensional accuracy and consistency of steel sheets, ensuring precise and uniform products. Lastly, cold-rolled steel has better formability, allowing manufacturers to easily bend, shape, or manipulate it into complex designs and structures, expanding the range of possibilities in product manufacturing.

Wholesale Cold Rolled Steel from supplier in Thailand

We are a Cold Rolled Steel supplier serving the Thailand, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Thailand region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Thailand. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Thailand, we can also provide valuable experience for your projects.