Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Industrial Aluminium Profile 6000 Series Description:

Industrial Aluminium Profile 6000 Series (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Industrial Aluminium Profile 6000 Series:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

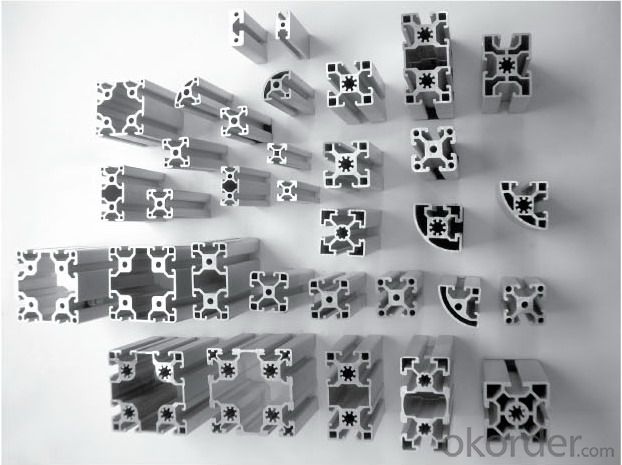

3.Industrial Aluminium Profile 6000 Series Images:

4.Industrial Aluminium Profile 6000 SeriesSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. It is a commonly used material due to its high thermal conductivity, lightweight nature, and excellent heat resistance properties.

- Q:How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q:How does the surface cleanliness of aluminum sheet affect its adhesion properties?

- The surface cleanliness of aluminum sheet has a significant impact on its adhesion properties. The presence of contaminants, such as dirt, grease, or oxide layers, on the surface can hinder the ability of adhesives to bond effectively with the aluminum sheet. A clean and properly prepared surface is essential for achieving strong adhesive bonds. When the aluminum sheet is free from contaminants, the adhesive can spread evenly and make intimate contact with the surface, resulting in a stronger bond. On the other hand, if the surface is not clean, the adhesive may not be able to adhere properly, leading to weak or unreliable bonds. In addition to contaminants, the presence of oxide layers on the aluminum surface can also affect adhesion properties. Aluminum naturally forms an oxide layer when exposed to air, which can hinder adhesive bonding. This oxide layer needs to be removed or modified to ensure good adhesion. Surface preparation methods like cleaning, degreasing, and treating with chemical solutions can help remove or modify the oxide layer, allowing for better adhesion. Various surface cleaning techniques can be employed to improve the cleanliness and adhesion properties of aluminum sheets. These can include mechanical cleaning methods such as abrasive cleaning or sanding, solvent cleaning, acid etching, or even plasma cleaning. Each method is selected based on the type and extent of contamination present on the surface. In summary, the surface cleanliness of aluminum sheet directly affects its adhesion properties. A clean and properly prepared surface ensures better adhesion by allowing the adhesive to make intimate contact with the aluminum sheet. Therefore, it is crucial to consider and address surface cleanliness when attempting to achieve strong and reliable adhesive bonds with aluminum sheets.

- Q:Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

- Q:What is the fatigue strength of 101 aluminum sheets?

- The fatigue strength of 101 aluminum sheets refers to their ability to withstand repeated loading and unloading cycles without experiencing failure or damage due to fatigue.

- Q:6061-T6 can aluminum sheets be bent?

- Landlord problem solving, no, I'm with you the same situation, into a batch of 2mm thick black, bending no problem, 3mm shine fold, 90 degrees bend ninety percent off break, I use punch press die bending

- Q:Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- they are none too bright!! We save pull tabs for our church, we find that saving the tab is worth more than the whole can! The can requires a lot of storage while you can get a denser pack into a 55 gal drum with just the tabs. I do not know the current price of aluminum per pound. I do not know the weight of a gallon jug filled with pull tabs SORRY! I do know that the other posters have no idea of what they say or think they know. All I can say, is start collecting and weigh it when you are done. I do know that our church finds this a worthy project, they make a bunch of money for something that would be trashed or otherwise disposed of... FYI, a black bag filled with cans will get you about $8.00US

- Q:How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q:Are the aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. They offer a sleek and modern look, are lightweight, durable, and versatile, making them an ideal choice for various decorative applications such as wall panels, signage, ceilings, and furniture. Additionally, aluminum sheets can be easily customized, painted, or engraved to create unique and visually appealing designs.

- Q:What are the different finishes available for aluminum sheets?

- Aluminum sheets offer a variety of finishes, each possessing unique characteristics and advantages. Some commonly used finishes include: 1. Mill finish: This is the most basic finish, giving aluminum sheets a smooth and shiny surface. It is achieved through the rolling mill process, maintaining the natural appearance. Mill finish is commonly preferred in industrial applications where aesthetics are not a primary concern. 2. Anodized finish: Anodizing involves an electrochemical process that adds an oxide layer to the aluminum sheet, enhancing durability and corrosion resistance. Anodized finishes can range from clear to various colors, and can be dyed to achieve specific shades. 3. Brushed finish: By brushing the aluminum sheet with abrasive materials, a pattern of fine lines is created on the surface, resulting in a distinctive textured appearance. Brushed finishes are often used in architectural and decorative applications. 4. Polished finish: Polishing aluminum sheets involves buffing the surface to a high shine, producing a mirror-like, reflective finish. This finish is commonly chosen for decorative purposes, such as in interior design, automotive detailing, or jewelry making. 5. Embossed finish: Embossing creates raised patterns or designs on the aluminum sheet, adding texture and visual interest. It can be achieved through roll embossing or stamping methods and is commonly used for decorative purposes or to enhance grip in certain applications. 6. Powder-coated finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat, resulting in a tough, durable, and visually appealing finish. Powder-coated finishes are available in a wide range of colors and offer excellent resistance to fading, chipping, and scratching. These are just a few examples of the diverse finishes available for aluminum sheets. The choice of finish will depend on the specific requirements of the application, including aesthetics, durability, and functionality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords