Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hygienic Green PVC Conveyor Belts In Food Industry

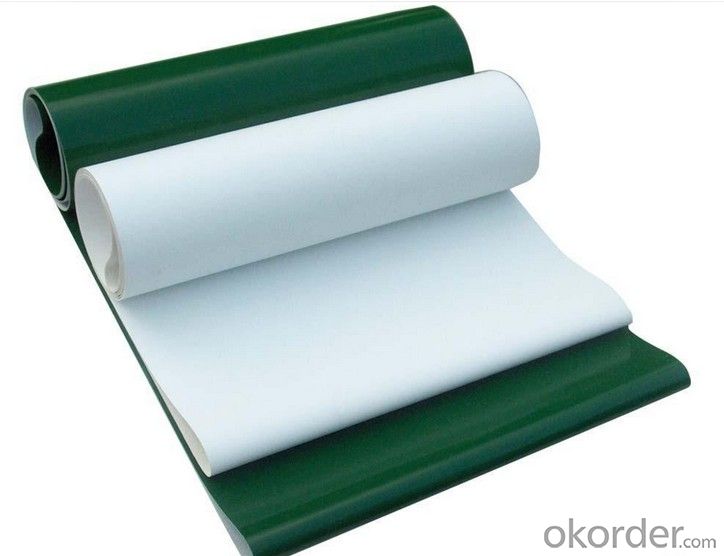

Descriptions of PVC Food Conveyor Belt

We are a highly reputed organization engaged in manufacturing and distribution of hygienic conveyor belts and food conveyor belts. Fabricated from FDA approved polymers, these food conveyor belts are available in high abrasion resistant, anti-static and oil resistant cover grades. Complying with ISO standards, these food belts are dimensionally accurate and available in standard as well as customized specifications.

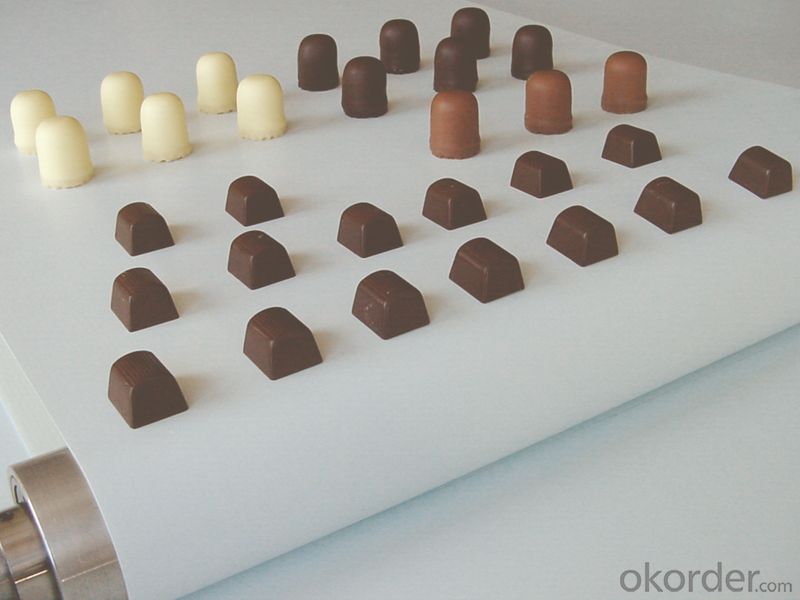

These hygienic conveyor belts do not stain and odorize the materials to be conveyed and widely used in the food industries for appropriate handling of food stuffs. Our range of hygienic belts is stringently quality checked to ensure that they are free from any kind of defect.

Features of PVC Food Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

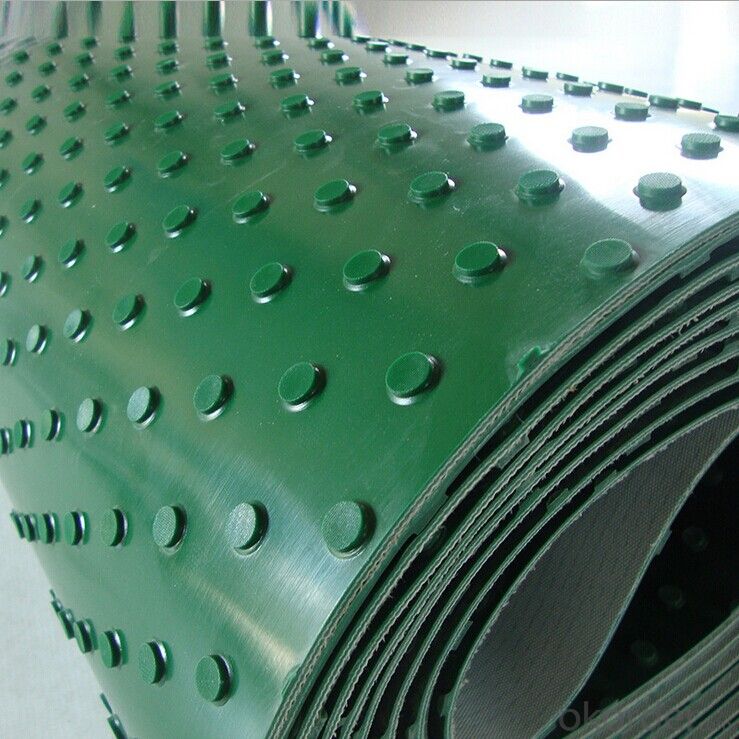

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

Application areas of PVC Food Conveyor Belt

Most popular application include operations in the Sugar IndustryFood Products Organizations mainly use Hygienic Belts for their bulk handling packed materials.

Tea Estates are major users of Hygienic Belts for conveying of various varieties of Green Tea Leaves and forward conveying the same towards Drier Sections, and finally for the packed products.

Pharmaceutical Sectors are major user of Hygienic Belts in their manufacturing units for medicines and packing departments.

Sepcifications of PVC Food Conveyor Belt

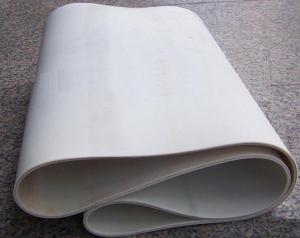

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How can I make rubber products brighter?

- The release agent shall have greater tensile strength so that it is not easy to be polished when it is in contact with the molding resin. This is especially true when there are frosted mineral fillers or glass fiber reinforcements in the resins. The release agent shall be chemically resistant so as not to be dissolved in contact with the chemical constituents of different resins (especially styrene and amines). Release agent should also have heat and stress properties, not easy to decompose or wear; release agent should be bonded to the mold, and not transferred to the processed parts, so as not to interfere with painting or other two processing operations.

- Q:Can the rubber surface be painted with paint?

- As long as waterproof, dustproof, isolated air is conducive to prolonging the service life of rubber. It can be applied with Vaseline, methyl silicone oil and so on.

- Q:Several aspects of rubber aging performance and how to identify them

- Oxygen, oxygen free radical chain reaction in rubber with rubber molecules, the molecular chain rupture or excessive crosslinking caused by rubber performance. Oxidation is one of the important reasons for aging of rubber

- Q:How much is the recipe for Buddha's rubber?

- Bo siangong Zhejiang university disciplinary advantage and analysis of detection rely on talent, with a variety of methods of analysis and testing, has accumulated rich experience in chemical products analysis, qualitative analysis and quantitative identification of unknown compounds through professional, reliable, comprehensive separation and detection means for adjusting the formula, in the research and production of new product development, to provide scientific production process improvement on the basis of, can also according to customer needs, provide follow-up technical guidance.

- Q:What is rubber made of?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q:What are the hazards of rubber accelerators?

- I have been engaged in the rubber industry for many years. I personally think that the accelerator has no harm to people. Wearing gloves, masks and protective measures during operation will not be harmful.

- Q:UV glue can glue rubber products?

- If only the outside screen is glued, the UV glue with a surface fixing type is OK (if the crack is too big and the glue can seep in, it is not recommended to mend), but the crack can still be seen.

- Q:Are rubber products poisonous? What harm?

- A product of a combination of many components, produced by certain cross reactions, with high elasticity. In general by the rubber, filler, plasticizer, active agent, accelerator, curing agent and other additives (pigment, odor, conductive composition etc.).

- Q:Why is natural rubber a strategic material?

- Rubber is an important strategic material, in the national defence application is very extensive, for example, a tank with more than 800 kg of general rubber; thirty thousand ton warship with sixty-eight tons of rubber, military equipment, air force facilities, almost all defense engineering rubber footprint. The use of rubber made ship, tent, warehouse and protective equipment, clothing etc. there are many varieties of bath water. As for the anti - tip technology needs high temperature, low temperature, oil resistance, high vacuum resistance and other special properties of the rubber, the constitution of 0 products is indispensable. With the development of national defense modernization, rubber, which is capable of resisting the temperature range of minus 100-400 DEG C and capable of resisting various acids, bases and oxidants with special properties, is being developed and manufactured.

- Q:How to solve the exhaust problem in rubber vulcanization process

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords