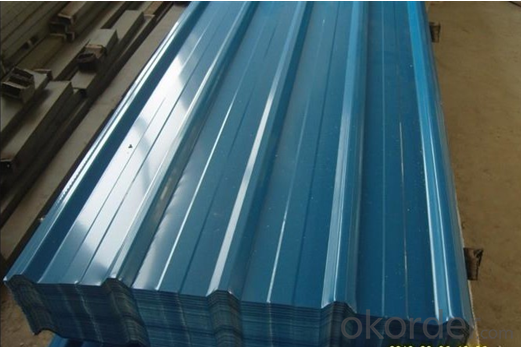

Hot-Dip Galvanized/Aluzinc Steel/Manufacturer Pre-Painted Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1) Standard: JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

2) Grade:DX51D+Z

3) Thickness: 0.12mm-0.6mm, all available

4) Width: 600mm-1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Hardness:Soft,full hard

8) Zinc Coating: 50-150g

9) Paint coating: Top 15-20mirco ,back 7mirco

10) Color series: Sea blue,white grey and all RAL color

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q:How do steel coils contribute to the agricultural industry?

- The agricultural industry relies heavily on steel coils as a crucial component for the production and maintenance of various agricultural machinery and equipment. These coils are primarily used to manufacture farm equipment like tractors, plows, harvesters, and irrigation systems. One of the key benefits of steel coils is their durability and strength, which makes them ideal for agricultural applications. These coils are processed and shaped into different sizes to create robust components that can withstand the demanding conditions and heavy workloads typically associated with farming operations. Steel coils are widely used in constructing tractor frames, ensuring the vehicles' structural integrity and stability. They are also utilized in manufacturing plow blades, providing the necessary strength to effectively cut through the soil and prepare the land for planting. Moreover, steel coils are crucial in creating harvester blades, which enable efficient harvesting and minimize crop damage. In addition to machinery, steel coils play a vital role in the production of irrigation systems, which are essential for agricultural practices. These systems require pipes and tubes that can endure high water pressures and resist corrosion caused by the elements. Steel coils are processed into these pipes and tubes, ensuring their durability and longevity, and thereby facilitating efficient water management and irrigation in fields. Furthermore, steel coils contribute to the agricultural industry by ensuring the secure storage and transportation of agricultural products. They are used in constructing storage silos and grain bins, which provide safe and weather-resistant spaces for storing crops. Steel coils are also utilized in fabricating transportation containers like trailers and trucks, ensuring the safe delivery of agricultural goods from farms to markets. In summary, steel coils have a significant impact on the agricultural industry. Their strength, durability, and versatility make them essential for manufacturing agricultural machinery, irrigation systems, storage facilities, and transportation containers. By providing reliable and efficient equipment, steel coils contribute to increased productivity, improved crop yields, and enhanced overall efficiency in the agricultural sector.

- Q:I want to know if Diamond is stronger than Steel.

- What Is Stronger Than Diamond

- Q:How do steel coils perform in extreme weather conditions?

- Steel coils generally perform well in extreme weather conditions. Steel is a durable and strong material that can withstand high temperatures, extreme cold, and harsh weather elements such as rain, snow, and wind. It has excellent resistance to corrosion, making it suitable for various outdoor applications. However, it is important to note that the performance of steel coils can vary depending on factors such as the specific grade of steel used, protective coatings applied, and the maintenance and care provided.

- Q:How are steel coils processed for slitting or shearing?

- Steel coils are processed for slitting or shearing by first uncoiling the coil and then feeding it through a slitter or shear machine. The machine applies pressure or cuts the steel coil into narrower strips or smaller pieces, respectively. This allows for the production of various widths or sizes of steel products, which can be used in different industries.

- Q:What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes that are used in various industries. 1. Shearing: This is the most common and simplest method of steel coil cutting. It involves using a shear blade to cut the coil material into desired lengths. Shearing can be done manually or with the help of automated machinery. 2. Slitting: Slitting is a process used to cut wide coils into narrower strips. It involves passing the coil material through a set of circular knives that cut the steel into multiple smaller coils or strips of desired width. 3. Laser cutting: Laser cutting is a highly precise and efficient method of cutting steel coil. It involves using a high-powered laser to melt or vaporize the material along a predetermined path. Laser cutting is commonly used for intricate designs or when high accuracy is required. 4. Plasma cutting: Plasma cutting is another method used to cut steel coil. It involves using a plasma torch that generates a high-velocity jet of ionized gas to melt the material. Plasma cutting is known for its speed and ability to cut through thick materials. 5. Waterjet cutting: Waterjet cutting is a process that uses a high-pressure stream of water mixed with abrasive particles to cut through steel coil. This method is often used when the material being cut is sensitive to heat or when precision is required. 6. Saw cutting: Saw cutting is a traditional method of cutting steel coil. It involves using a saw blade with teeth to cut through the material. Saw cutting is effective for thicker materials and can be done manually or with the help of automated machinery. These are just a few of the different types of steel coil cutting processes that are commonly used. The choice of cutting method depends on factors such as the type and thickness of the material, desired accuracy, speed, and cost-effectiveness.

- Q:What are the different types of steel coil cutting tools?

- In the market, one can find a variety of steel coil cutting tools. These tools have been specifically designed to efficiently and accurately cut steel coils. Some of the commonly used types of steel coil cutting tools include: 1. Slitting shears: These shears are widely utilized to cut steel coils into narrow strips. Equipped with multiple blades, slitting shears offer clean and precise cuts without causing any damage to the material. They are typically employed in high-volume production and are capable of handling different thicknesses of steel coils. 2. Rotary shears: Another commonly used cutting tool for steel coils is the rotary shear. These shears consist of rotating blades that shear through the material as it passes through them. Rotary shears are perfect for cutting medium to thick steel coils and are known for their high cutting speed and accuracy. 3. Guillotine shears: Guillotine shears are heavy-duty cutting tools that can handle thick steel coils. They operate by exerting a downward force to cut through the material in one clean stroke. Renowned for their power and precision, guillotine shears are suitable for cutting large volumes of steel coils. 4. Laser cutting machines: Advanced cutting tools like laser cutting machines employ a high-powered laser beam to cut through steel coils. These machines offer precise and intricate cuts with minimal heat distortion. Laser cutting machines are ideal for cutting complex shapes and patterns on steel coils. 5. Water jet cutting machines: Water jet cutting machines utilize a high-pressure stream of water mixed with abrasive particles to cut through steel coils. This method provides high accuracy and does not generate heat, making it suitable for cutting heat-sensitive materials. Water jet cutting machines can cut through various thicknesses of steel coils and produce smooth edges. Each type of steel coil cutting tool has its own advantages and is suitable for different applications. The choice of tool depends on factors such as the thickness of the steel coil, required precision, production volume, and budget.

- Q:What are the different types of steel coil coatings for heat resistance?

- There are several different types of steel coil coatings that provide heat resistance, including silicone-modified polyester (SMP), polyvinylidene fluoride (PVDF), and high-temperature silicone.

- Q:How are steel coils used in the manufacturing of metalworking tools?

- Steel coils are a crucial component in the manufacturing of metalworking tools. These coils, which are typically made from high-quality steel, are used in various stages of the production process to create different types of metalworking tools. One of the primary uses of steel coils in the manufacturing of metalworking tools is for the production of blades and cutting tools. The coils are typically cut into specific lengths and then shaped and sharpened to create the blades that are used for cutting, shaping, and milling various metals. The high-quality steel used in these coils ensures that the resulting blades are durable, strong, and capable of withstanding the demanding conditions of metalworking processes. Steel coils are also used in the manufacturing of drill bits and other types of metalworking tooling. The coils are shaped and machined to create the desired size and shape of the tool, and then hardened and tempered to increase their strength and durability. This ensures that the resulting tools can withstand the high-speed drilling and cutting operations involved in metalworking. Furthermore, steel coils are used to create the bodies and handles of metalworking tools. The coils are typically formed into the desired shape and size using various forming techniques such as bending, rolling, and stamping. These formed pieces are then welded or fastened together to create the final structure of the tool. The high-quality steel used in the coils ensures that the resulting tool bodies and handles are strong, rigid, and capable of withstanding the forces and vibrations associated with metalworking operations. In summary, steel coils play a vital role in the manufacturing of metalworking tools. They are used to create blades, drill bits, bodies, and handles, providing the necessary strength, durability, and precision that are required in metalworking processes. These coils are an essential raw material that enables the production of high-quality, reliable, and efficient metalworking tools.

- Q:Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q:Which one would be stronger? And should damascus steel be tempered?Thank You

- it depends on so many factors first of all is it functional damascus steel or can you see the grain? what type of carbon steel is it generally most makers use1045- 1060 a good quote of something I read was asking what steel is best for a sword is like asking how long string should be generally if they say carbon steel and do not say what grade it is they mean 1045 meaning it has 4.5 carbon content now this if properly tempered can make a good sword but it would not be known for it's durability or it's edge retention it would be average at these things as for damascus steel well as I said before it is just any steel that has been folded some people think it has magical properties imparted by the folding process but it is just steel there is slightly a higher chance of a damascus steel sword having deposits of impurities along the blade and at cheaper blades this risk is even higher that being said many good swords made of damascus on the market are very good quality any sword no matter if it is made of damascus, carbon, spring. or tool steel should be tempered always no question about that

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized/Aluzinc Steel/Manufacturer Pre-Painted Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords