Hot-dip Aluzinc Steel Building Roof Walls -the Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel Building Roof Walls -the Best Quality

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

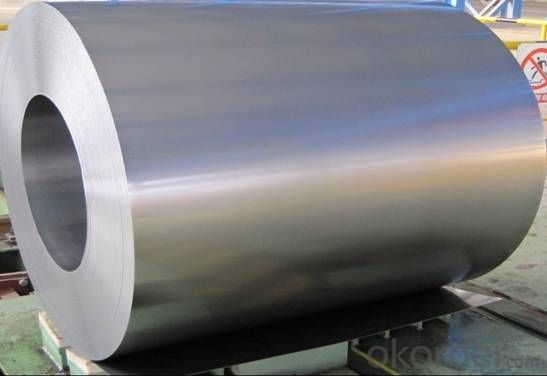

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q:How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they provide a convenient and efficient way to transport and store large quantities of steel. These coils are uncoiled and cut into desired sizes to construct various components of ships, such as hulls, decks, and superstructures. The versatility and strength of steel make it an ideal material for shipbuilding, and the use of coils ensures a reliable supply chain for this crucial industry.

- Q:What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific requirements, but it typically ranges from a few millimeters to several meters.

- Q:How are steel coils used in the manufacturing of metal structures?

- Steel coils are used in the manufacturing of metal structures as they provide a convenient and efficient way to shape and form steel into various components. These coils are often processed through rolling mills to produce sheets or plates, which can then be cut, bent, or welded to create structural elements such as beams, columns, and trusses. The use of steel coils ensures uniformity, strength, and flexibility in the manufacturing process, allowing for the production of durable and reliable metal structures.

- Q:Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- No. Steel does not build up static electricity by itself. Also, magnetic fields are made by moving electricity, not static electicity. The steel conducts magnetism, so it changes the earth's magnetic field near itself by conducting the field through itself. The larger effect is a magnet near a piece of steel: the compass has a magnet, and when you place it near a ferromagnetic material, it attracts. Try putting a refridgerator magnet against the fridge - it sticks because it attracts.

- Q:Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel Remington Tompkins Steel Ryder Tompkins Steel Sargent Tompkins Steel Thor Tompkins

- Q:How are steel coils used in the manufacturing of marine equipment?

- Steel coils are used in the manufacturing of marine equipment as they provide the necessary strength and durability required for the construction of various components such as ship hulls, bulkheads, decks, and structural supports. These coils are typically used as raw material for cutting, shaping, and welding into the required shapes and sizes, ensuring the marine equipment can withstand the harsh conditions of the sea and maintain its structural integrity.

- Q:The difference between aluminized color steel roll and ordinary color steel roll

- Ordinary color steel roll is a composite material, also known as color coated steel plate, is used in the continuous production line on the production line after surface degreasing, phosphating and other chemical coating treatment, painted with organic coatings, made by baking products. Both steel and organic materials are a little bit different. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance.

- Q:is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Trauma center is awesome. Red steel isn't bad. Same as any other FPS except with a pointer... It's no half life, but its not terrible. Multiplayer is highly entertaining though. Especially if you can get four people playing mystery mode. Trust me, its worth the effort of getting them together. Like the other guy said, rent it. I wouldn't buy it.

- Q:Steels like YHB-2, MVS-8, and SK-5. Also if you know anything about these steels that would be helpful.

- White steel is a common shorthand name for white paper steel (shirogami hagane) which can be any of several fairly simple high carbon, water hardening steel grades. The carbon content varies by grade, and runs from 0.8 to 1.4%. The range of carbon content within a grade is a tight 0.1%. For example, the carbon content of Shirogami Hagani No1A is specified to be between 1.3 and 1.4%. Each grade also contains 0.1-0.2% silicon and 0.2-0.3% manganese, and only trace amounts of the impurities sulfur and phosphorus. Blue paper steel (aogami hagane) is also offered in several grades, with carbon content ranging similarly to the white grades. However, blue steel contains the additional alloying elements chromium and tungsten, and one grade (aogami super) also contains molybdenum and vanadium. The blue steels can be quenched in water or oil, whereas most of the white grades need a faster quench and require water.

- Q:What are the common methods of joining steel coils?

- Various techniques can be employed to join steel coils, depending on the desired outcome and specific application. Butt welding is a commonly utilized method wherein the two ends of the steel coils are aligned and welded together. Gas welding, electric resistance welding, or laser welding can be employed for this purpose. This technique yields a strong and continuous joint without the need for additional material. For temporary or low-stress applications where disassembly may be necessary, overlapping and stitching is an option. In this technique, one end of the steel coil is overlapped onto the other end and fastened together using mechanical means such as staples, nails, or screws. Mechanical couplings are another means of joining steel coils. These couplings are designed to fit over the coil ends and securely hold them together. They are commonly used in pipelines where the joint must be leak-proof and capable of withstanding high pressure. Adhesive bonding is a method that involves applying a suitable adhesive or bonding agent to the coil ends and pressing them together. This technique results in a clean and visually appealing joint, although the strength may vary depending on the adhesive used. Similar to overlapping and stitching, overlapping and welding involves overlapping the coil ends and welding them together. However, instead of using mechanical fasteners, welding is employed to create a stronger and more permanent joint. This method is frequently employed in structural applications that require high strength and durability. It should be noted that the selection of a joining method depends on factors such as the type of steel, application requirements, and desired joint strength. Careful consideration should be given to ensure that the chosen method is suitable for the specific project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Aluzinc Steel Building Roof Walls -the Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords