All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are stainless steel coils formed into specific shapes or profiles?

Stainless steel coils are formed into specific shapes or profiles through a process called cold rolling. During this process, the stainless steel coil is passed through a series of rollers that gradually shape and form it into the desired profile. This cold rolling method allows for precise control over the dimensions and characteristics of the stainless steel, ensuring it meets the required specifications for its intended use.

What is the corrosion resistance of stainless steel coil?

The corrosion resistance of stainless steel coil is excellent due to the presence of chromium in its composition, which forms a protective layer on the surface and prevents rusting and corrosion.

How is stainless steel coil used in the telecommunications manufacturing industry?

Stainless steel coil is commonly used in the telecommunications manufacturing industry for various applications. It is primarily utilized in the production of antenna systems, satellite dishes, and communication towers. Due to its corrosion resistance and durability, stainless steel coil provides structural strength and reliability to these components, ensuring their long-term functionality in diverse weather conditions. Additionally, stainless steel coil is also used in the manufacturing of connectors, cables, and other telecommunications equipment, where its high electrical conductivity and resistance to electromagnetic interference are crucial factors. Overall, stainless steel coil plays a vital role in the telecommunications industry by providing the necessary strength, durability, and electrical properties required for efficient and reliable communication systems.

Can stainless steel coils be used for structural applications?

Yes, stainless steel coils can be used for structural applications. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it suitable for various structural uses such as in buildings, bridges, and automotive components. The coils can be formed, shaped, and welded to meet the specific requirements of different structural applications.

How does the ductility of stainless steel coils compare to other materials?

The ductility of stainless steel coils is generally higher compared to most other materials. Due to its composition and manufacturing process, stainless steel can be easily formed and shaped without losing its strength and structural integrity. This makes it a highly preferred material in various industries where flexibility and durability are critical requirements.

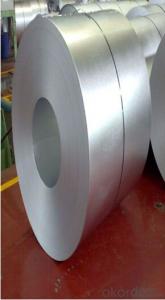

Wholesale Stainless Steel Coil from supplier in Swaziland

Our Stainless Steel Coils are sourced from reputable manufacturers and undergo strict quality control procedures to ensure that you receive only the highest quality products. We offer a wide range of grades and finishes to suit your specific requirements.

In addition to supplying Stainless Steel Coils, we also provide value-added services such as cutting, slitting, and polishing. Our experienced team can assist you in finding the right solution for your project and provide technical support throughout the process.

We understand the importance of timely delivery and strive to ensure that your orders are delivered on time and in perfect condition. Our efficient logistics network allows us to deliver Stainless Steel Coils to any location in Swaziland.

As a subsidiary of CNBM, we have the advantage of leveraging the global network and resources of a Fortune Global 500 company. This enables us to offer competitive prices and comprehensive procurement solutions for Stainless Steel Coils in Swaziland.

Contact us today to discuss your requirements and let us provide you with the best Stainless Steel Coil solutions for your projects in Swaziland.

In addition to supplying Stainless Steel Coils, we also provide value-added services such as cutting, slitting, and polishing. Our experienced team can assist you in finding the right solution for your project and provide technical support throughout the process.

We understand the importance of timely delivery and strive to ensure that your orders are delivered on time and in perfect condition. Our efficient logistics network allows us to deliver Stainless Steel Coils to any location in Swaziland.

As a subsidiary of CNBM, we have the advantage of leveraging the global network and resources of a Fortune Global 500 company. This enables us to offer competitive prices and comprehensive procurement solutions for Stainless Steel Coils in Swaziland.

Contact us today to discuss your requirements and let us provide you with the best Stainless Steel Coil solutions for your projects in Swaziland.