All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures can be taken to prevent steel pipes from corroding in industrial wastewater systems?

There are several measures that can be taken to prevent steel pipes from corroding in industrial wastewater systems. Firstly, using corrosion-resistant coatings such as epoxy or polyethylene can provide a protective barrier on the surface of the pipes. Additionally, regular inspections and maintenance should be conducted to identify and repair any signs of corrosion promptly. Implementing cathodic protection techniques like sacrificial anodes or impressed current systems can also help prevent corrosion by diverting the electrical current away from the pipes. Properly managing the wastewater chemistry, including controlling pH levels and removing harmful contaminants, is crucial to minimizing corrosion. Lastly, ensuring proper water treatment and filtration processes can prevent the accumulation of corrosive substances and reduce the risk of corrosion in the pipes.

What measures can be taken to prevent steel pipes from becoming magnetized and interfering with sensitive equipment and instruments?

One measure to prevent steel pipes from becoming magnetized and interfering with sensitive equipment and instruments is to use non-magnetic stainless steel pipes instead. These pipes are made from alloys that have a lower magnetic permeability, reducing the chances of magnetization. Additionally, installing magnetic shields around the sensitive equipment and instruments can also help to mitigate any potential magnetic interference from the steel pipes.

What is the purpose of coating steel pipes with various materials, such as epoxy or polyethylene?

The purpose of coating steel pipes with various materials, such as epoxy or polyethylene, is to protect them from corrosion and extend their lifespan. These coatings act as a barrier between the steel and the surrounding environment, preventing the pipe from coming into direct contact with moisture, chemicals, or other corrosive substances. This helps to prevent rusting and degradation of the steel, ensuring the integrity and longevity of the pipes. Additionally, these coatings can also provide added insulation, improve flow efficiency, and reduce friction within the pipes.

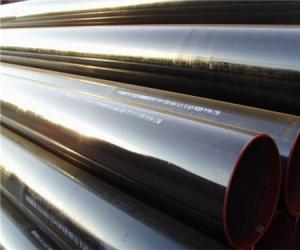

Wholesale Steel Pipes from supplier in Swaziland

With our expertise in supplying Steel Pipes to Swaziland, we can offer you a wide range of products to meet your specific requirements. Whether you need seamless or welded pipes, carbon steel or alloy steel pipes, or various sizes and specifications, we have you covered.

Our sales team is dedicated to understanding your needs and providing you with personalized solutions. We will work closely with you to ensure that you receive the right products at competitive prices.

In addition to sales, we also offer quotation services to provide you with accurate and transparent pricing information. Our team will promptly respond to your inquiries and provide detailed quotations tailored to your project requirements.

Furthermore, we understand the technical aspects of Steel Pipes and can provide you with expert technical support. Whether you need assistance with product selection, material specifications, or installation guidelines, our knowledgeable team is here to help.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and networks. This allows us to provide you with all-in-one procurement services, streamlining the process and ensuring efficiency. From product sourcing and quality control to logistics and delivery, we have the capability to handle all aspects of your procurement needs.

Our years of market development in Swaziland have given us a deep understanding of the local industry and regulations. We are familiar with the specific challenges and requirements of projects in Swaziland, allowing us to offer invaluable expertise and guidance.

Partner with us for your Steel Pipe needs in Swaziland, and benefit from our comprehensive range of products, sales and quotation services, technical support, and all-in-one procurement services. Contact us today to discuss your project requirements and how we can assist you.

Our sales team is dedicated to understanding your needs and providing you with personalized solutions. We will work closely with you to ensure that you receive the right products at competitive prices.

In addition to sales, we also offer quotation services to provide you with accurate and transparent pricing information. Our team will promptly respond to your inquiries and provide detailed quotations tailored to your project requirements.

Furthermore, we understand the technical aspects of Steel Pipes and can provide you with expert technical support. Whether you need assistance with product selection, material specifications, or installation guidelines, our knowledgeable team is here to help.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and networks. This allows us to provide you with all-in-one procurement services, streamlining the process and ensuring efficiency. From product sourcing and quality control to logistics and delivery, we have the capability to handle all aspects of your procurement needs.

Our years of market development in Swaziland have given us a deep understanding of the local industry and regulations. We are familiar with the specific challenges and requirements of projects in Swaziland, allowing us to offer invaluable expertise and guidance.

Partner with us for your Steel Pipe needs in Swaziland, and benefit from our comprehensive range of products, sales and quotation services, technical support, and all-in-one procurement services. Contact us today to discuss your project requirements and how we can assist you.