All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What factors determine the choice of aluminum sheet alloy series for specific applications?

The choice of aluminum sheet alloy series for specific applications is determined by several factors including the desired mechanical properties, corrosion resistance, formability, weldability, and cost considerations. The specific application requirements, such as strength, hardness, and conductivity, play a significant role in selecting the appropriate alloy series. Additionally, factors like the operating environment, temperature variations, and surface finish requirements further influence the choice of aluminum sheet alloy series.

What are the best practices for recycling aluminum sheets to maintain material quality and minimize environmental impact?

The best practices for recycling aluminum sheets to maintain material quality and minimize environmental impact include the following steps:

1. Collection and sorting: Implement an efficient collection system to gather aluminum sheets separately from other materials. Proper sorting is crucial to ensure that only clean and pure aluminum sheets are recycled.

2. Cleaning and preparation: Remove any contaminants, such as paint, adhesives, or other non-aluminum materials, from the sheets. This can be done through mechanical or chemical processes, ensuring that the aluminum remains pure.

3. Shredding and melting: Shred the cleaned aluminum sheets into smaller pieces to increase surface area and facilitate the melting process. Melt the shredded aluminum in a furnace or a smelter, ensuring that the temperature and composition are controlled to produce high-quality recycled aluminum.

4. Purification and alloying: Purify the molten aluminum by removing impurities like iron, copper, or zinc. This can be achieved through various techniques like filtration or chemical reactions. Additionally, alloying agents may be added to enhance the properties of the recycled aluminum, depending on the intended application.

5. Energy-efficient processes: Opt for energy-efficient technologies and practices throughout the recycling process. This includes utilizing renewable energy sources, optimizing furnace operations, and minimizing energy consumption during transportation and other stages.

6. Recycled content utilization: Encourage the use of recycled aluminum sheets in various industries and applications. Promote the benefits of using recycled materials, such as reduced energy consumption and lower carbon footprint, to create a market demand for recycled aluminum.

7. Continuous improvement: Regularly evaluate and improve recycling processes to ensure maximum material quality and minimize environmental impact. Stay updated with advancements in recycling technologies and techniques that can further enhance the efficiency and sustainability of aluminum sheet recycling.

By adhering to these best practices, we can effectively recycle aluminum sheets, maintain material quality, and minimize the environmental impact associated with their production and disposal.

How do you determine the appropriate gauge of an aluminum sheet?

The appropriate gauge of an aluminum sheet is determined primarily by considering the specific application or purpose for which the sheet will be used. Factors such as the required strength, durability, and weight-bearing capacity, as well as any specific industry standards or regulations, all play a role in determining the appropriate gauge. Additionally, factors like cost, availability, and ease of fabrication may also be considered. It is essential to consult relevant engineering or industry guidelines, consult with experts, or conduct tests to ensure the aluminum sheet's gauge meets the necessary requirements for the intended use.

Wholesale Aluminum Sheets from supplier in Swaziland

With our reliable supply chain and efficient logistics, we ensure timely delivery of Aluminum Sheets to any location in Swaziland. Our products are sourced from trusted manufacturers and undergo strict quality control measures to ensure they meet international standards.

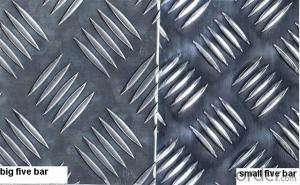

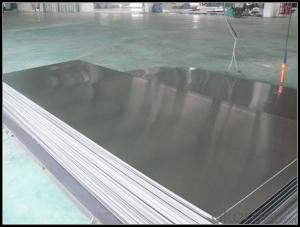

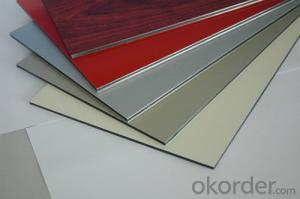

We offer a diverse range of Aluminum Sheets to suit various applications, including construction, automotive, aerospace, and manufacturing. Our sheets come in different sizes, thicknesses, and finishes to meet your specific requirements. Whether you need flat sheets, perforated sheets, or embossed sheets, we have the solution for you.

Our team of experienced professionals is committed to providing exceptional customer service. We understand the importance of prompt and accurate responses to inquiries, as well as providing detailed quotations that meet your budget. Our technical support team is always available to assist you with any product-related questions or concerns.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company. This gives us access to a vast network of resources and expertise, ensuring that you receive the best possible products and services. We are constantly innovating and staying up-to-date with industry trends to provide cutting-edge solutions to our customers.

Choose us as your trusted supplier of Aluminum Sheets in Swaziland and experience a seamless procurement process. Contact us today to discuss your requirements and let us provide you with the highest quality products and support for your projects.

We offer a diverse range of Aluminum Sheets to suit various applications, including construction, automotive, aerospace, and manufacturing. Our sheets come in different sizes, thicknesses, and finishes to meet your specific requirements. Whether you need flat sheets, perforated sheets, or embossed sheets, we have the solution for you.

Our team of experienced professionals is committed to providing exceptional customer service. We understand the importance of prompt and accurate responses to inquiries, as well as providing detailed quotations that meet your budget. Our technical support team is always available to assist you with any product-related questions or concerns.

As a subsidiary of CNBM, we have the backing of a Fortune Global 500 company. This gives us access to a vast network of resources and expertise, ensuring that you receive the best possible products and services. We are constantly innovating and staying up-to-date with industry trends to provide cutting-edge solutions to our customers.

Choose us as your trusted supplier of Aluminum Sheets in Swaziland and experience a seamless procurement process. Contact us today to discuss your requirements and let us provide you with the highest quality products and support for your projects.