All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

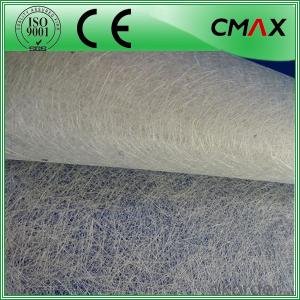

Fiberglass Chopped StrandView More

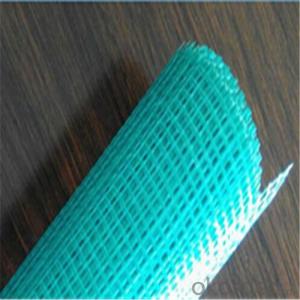

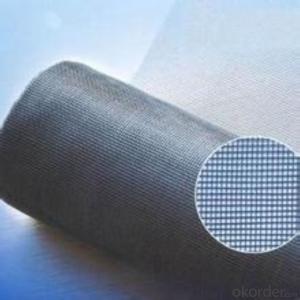

Fiberglass Mesh ClothView More

Composite PipesView More

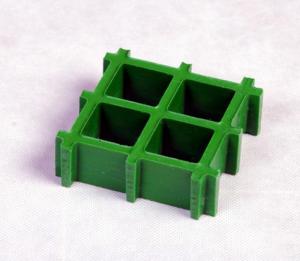

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Can fiberglass be used for making automotive accessories or trims?

Yes, fiberglass can be used for making automotive accessories or trims. It is a versatile material that is lightweight, durable, and easily molded into various shapes and designs, making it ideal for creating automotive components such as spoilers, body kits, grilles, and interior trims. Additionally, fiberglass is resistant to corrosion and can be painted to match the vehicle's color, providing a seamless integration with the overall aesthetic of the car.

What are the different fiberglass manufacturing processes?

There are several different fiberglass manufacturing processes, but the most common ones include hand lay-up, spray-up, and filament winding. Hand lay-up involves manually laying fiberglass sheets onto a mold and applying resin by hand. Spray-up is a similar process, but the resin and fibers are sprayed onto the mold using a spray gun. Filament winding, on the other hand, involves winding continuous fibers around a rotating mandrel to create a reinforced composite structure. These processes can vary in complexity and are chosen based on the desired end product and manufacturing requirements.

How is fiberglass used in the production of helmets?

Fiberglass is used in the production of helmets as it provides strength and durability. It is typically used to create the outer shell of the helmet, offering protection against impacts and abrasions. The fiberglass material is lightweight, making it comfortable for the wearer while still providing necessary protection.

Can fiberglass be used for structural purposes?

Yes, fiberglass can be used for structural purposes. It is a lightweight and strong material that is commonly used in the construction industry for applications such as reinforcing concrete, building boat hulls, and manufacturing structural components.

What are the different temperature resistance options available for fiberglass supply?

There are various temperature resistance options available for fiberglass supply, including standard temperature resistance, high-temperature resistance, and extreme temperature resistance. These options allow fiberglass materials to withstand different temperature ranges, ensuring their suitability for specific applications and environmental conditions.

Wholesale Fiberglass Supply from supplier in Swaziland

Thank you for considering our Fiberglass Supply supplier in Swaziland. We are confident that we can meet your needs and provide you with exceptional service. Our company is backed by the expertise and resources of CNBM, a Fortune Global 500 company, ensuring that we can deliver comprehensive procurement solutions.

We understand the unique challenges and requirements of the Swaziland market, and our years of experience in the industry make us well-equipped to provide valuable insights and expertise. Whether you are in the construction, industrial, or any other sector, we have the knowledge and products to meet your specific needs.

Customer satisfaction is our top priority, and our team of professionals is committed to providing you with top-notch assistance. From helping you select the right products to offering technical guidance, we are here to ensure that you make informed decisions and achieve the highest level of efficiency in your projects.

We invite you to partner with us for all your Fiberglass Supply needs in Swaziland. Experience the convenience, reliability, and expertise that our company brings to the table. Contact us today to discuss your requirements, and let us exceed your expectations. We look forward to serving you.

We understand the unique challenges and requirements of the Swaziland market, and our years of experience in the industry make us well-equipped to provide valuable insights and expertise. Whether you are in the construction, industrial, or any other sector, we have the knowledge and products to meet your specific needs.

Customer satisfaction is our top priority, and our team of professionals is committed to providing you with top-notch assistance. From helping you select the right products to offering technical guidance, we are here to ensure that you make informed decisions and achieve the highest level of efficiency in your projects.

We invite you to partner with us for all your Fiberglass Supply needs in Swaziland. Experience the convenience, reliability, and expertise that our company brings to the table. Contact us today to discuss your requirements, and let us exceed your expectations. We look forward to serving you.

Hot Search

- Fiberglass Chopped Strand in Sri Lanka

- Fiberglass Mesh Cloth in Luxembourg

- Composite Pipes in Germany

- FRP Pultrusion Profiles in Lithuania

- Fiberglass Mat Tissue in Cambodia

- Fiberglass Fabrics in America

- Fiberglass Mesh in Bhutan

- Composite Tank in Vanuatu

- Fiberglass Mesh tape in Austria

- Polymer in Jamaica