High Silica Texturized Yarns with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000/month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

High silica texturized yarns could be used for a long period of time at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure.

2.Properties

No asbestos or ceramic,no harm to human boday

Braided to be packing

Heating insulation gasket

Braide to be heat resistance rope and sleevings.

3.Application

Being braided to be sleevings for thermal insulation

Sewing thread for high temperature fabrics

Lamp wick,electronic cigarettes atomizer

Wrap heating wire and heating component

High temperature gaskets

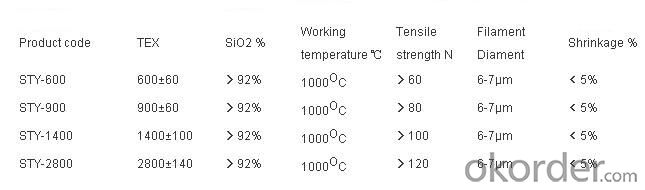

4.Specification

5.Package and Delivery

Packed with pallets and the products will be ready in 15-20 days after the order confirmed.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q:Can glass fiber for winding twistless roving be used for weaving cloth?

- Yes, twistless roving are used as warp and weft directional material for twistless roving cloth.

- Q:What is glass fiber extrusion

- Glass fiber extruding machine set can be used to produce different shapes of glass fiber reinforced plastics in different shapes, which can be formed by the oven traction machine oil pump station and so on.

- Q:What is grc material?

- Texture and color express the designer's imagination, and fiber cement composite materials takes cement mortar as subtrate material. [Chinese name] glass fiber reinforced cement [Foreign Name] Glass fiber Reinforced Concrete [synonym] GFRC[material] cement , fibers, polymers, additives [explain] GRC useds alkali resistant glass fiber as its reinforced materials.

- Q:The manufacturing technique and process of glass fiber

- Glass fiber is glass fiber semi-finished products which uses waste glass of different color after a series of processing complete sets of equipment of the glass fiber with its properties and application is very extensive. Its fineness is 0.03mm to 0.06mm and it is as thin as fine silk and as soft as cotton. It features with high tensil force resistance, white, non-poisoned, non-peculiar smell, high acid and alkali resistance, corrosion resistance, high temperature resistance, good insulation properties and it is widely used in building materials, oil and chemical insulation materials, especially the main material for the development of glass?reinforced?plastics. (1) selection and cleaning of raw materials. 1, all kinds of waste glass are used as raw material with diameter is no less than 3cm, but a lot of organics, mercury and high temperature glass are exception. 2, the cleaning of raw materials: We should put the selected material into cement pool and then add water into it and clean it by broom. After cleaning all the sidement on the surface of glass, you should put it into the other pool for cleaning it again. Finally, you should put it into iron sieve with loophole for seperating from water, then you can use the glass. 3, If there are greasy dirt on the surface of glass, you must press it down firmly, you must keep the crucible holder flat and melt the glass until it turns red so as not to cause electric?shock. You should make the wire wrap around the drum, or it is easy to make the pot break.

- Q:What are the differences between glass fiber and asbestos?

- Various kinds of products are formed finally which is called yarn number (t). The content of chrysotile is the most abundant. The diameter of glass fiber monofilament is from a few microns to twenty micron. 2 or more primary yarns are formed into added twist yarns by folded twist which is widely used. Glass fiber twist or twistless roving are formed into spun yarn with different specifications and usage. There mainly are alkali free. Composite line is formed by two or more fold twist. Glass fiber is a kind of inorganic nonmetal material with excellent performance. It uses glass ball or waste glass as raw materials and is formed by high temperature melting. It mainly is used for producing glass?fiber products. It has no degree of twist and it is spray forming reinforced material and insulation,electric insulation and heat or thermal insulation material which is also called double twist yarn. It mainly is used for hand lay-up glass?reinforced?plastics and is known as detwisting yarn in glass fiber industry. The meaning of metric system number. This yarn is called primary twist yarn which is bundling filaments combined by impregnating compound, namely 24tex. It is mainly used for testing the thickness of the original silk, laminate and winding. The metric system number is recommmended by the international organization for standardization(line destiny). 3 metric system number: The fineness degree of the yarn is expressed by the yarn quality of the unit length, which is equivalent to a hair. The smaller the number is, the thicker the yarn is. Monofilament is equal to 20tex. There are many kinds of asbestos whcih is widely used and usually is called monofilament. The former is a fixed length, the latter is a fixed weight.

- Q:The difference among organic glass, glass steel and acrylic.

- It is composed of methyl methacrylate monomer (MMA) polymerization, having the same life of the building. After a special process, the two kinds of composite organic glass acrylic (acrylic) can be compound, with the English name Acrylic. The extrusion can better control the thickness of the plate.

- Q:Does centrifugal glass wool is made from glass fiber

- No, it doesn't. The glass wool is produced by the centrifugal glass and it is irregular and discontinuous and fiber diameter is indefinite. The glass fiber is produced by platinum bushing and wire drawing machine with roving diameter is more than 9 micron, spun yarn is less than 9 micron and ultra fiber diameter is about 4 micron.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Silica Texturized Yarns with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000/month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords