High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

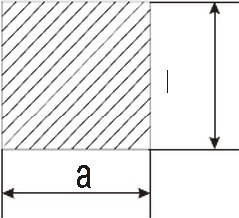

(The section of Square Steel)

Some details of Square Steel:

-List 1. The Chemical Composition.

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q235B |

C |

Mn |

S |

P |

Si |

|

0.12~0.20 |

0.3~0.7 |

≤0.045 |

≤0.045 |

≤0.3 | ||

-List 2.The length of a side and the theoretical weight of Square Steel.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 3. The allowed tolerance of Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Usage/Applications of Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for square tubes.

Packaging & Delivery of Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel:

- Q:How do you use a steel square to determine angles for stair nosing?

- To use a steel square to determine angles for stair nosing, you will need to follow these steps: 1. Place the steel square on the edge of the stair tread, aligning one of its legs with the vertical riser and the other leg with the horizontal tread. 2. Make sure the square is securely positioned against the edge of the tread and riser to obtain accurate measurements. 3. Once the square is properly aligned, use a pencil or marker to mark the angle on the tread. 4. Next, transfer the marked angle onto the stair nosing material. Place the square against the nosing material, aligning the leg with the edge that will be installed on the stair tread. 5. Use a pencil or marker to mark the angle on the material, ensuring that the line is clear and visible. 6. Finally, cut along the marked line using a saw or appropriate cutting tool to obtain the correct angle for the stair nosing. By using a steel square in this manner, you can accurately determine and transfer angles onto stair nosing material, ensuring a precise fit and a professional-looking finish for your stairs.

- Q:Can a steel square be used for pergola construction?

- Indeed, the utilization of a steel square is viable for constructing a pergola. Steel squares exhibit adaptability as tools, serving a multitude of functions in construction, which encompass measuring and delineating angles, examining for squareness, and guaranteeing precise and linear cuts. In relation to pergola assembly, a steel square can ascertain that the posts are appropriately aligned and that the beams and rafters are perpendicular. Moreover, it can be employed to gauge and indicate the correct dimensions and angles for slicing the lumber. All in all, a steel square serves as an invaluable instrument, ensuring meticulousness and correctness in the construction of a pergola.

- Q:How do you use a steel square to check for plumbness in a post?

- To use a steel square to check for plumbness in a post, you would hold the square against the side of the post, ensuring that the 90-degree angle of the square is flush with the side. Then, align the vertical edge of the square with the top edge of the post. If the post is plumb, the square's vertical edge will be perfectly aligned with the post's vertical edge. If there is any deviation, it indicates that the post is not plumb and adjustments need to be made.

- Q:Can a steel square be used for checking the squareness of cabinet frames?

- Yes, a steel square can be used for checking the squareness of cabinet frames. Steel squares are commonly used in carpentry and woodworking for measuring and verifying right angles. They are accurate and reliable tools for determining if cabinet frames are square and ensuring their proper alignment.

- Q:How do you use a steel square to measure and mark 191.25-degree angles?

- In order to measure and mark a 191.25-degree angle using a steel square, the following steps should be followed: 1. Firstly, align the long leg of the steel square with one side of the angle to be measured. Make sure that the shorter leg of the square is pointing towards the inside of the angle. 2. Next, rotate the steel square until the shorter leg's edge intersects with the other side of the angle. This will create a perpendicular line that intersects both sides of the angle. 3. Now, using a protractor or angle finder, measure and mark a 90-degree angle from the newly created line. This can be done by placing the protractor or angle finder along the line and ensuring that it reads 90 degrees. 4. Once the 90-degree angle has been marked, continue rotating the steel square in the opposite direction of the initial line, but still around the same point of intersection. Keep rotating until the desired 191.25 degrees is reached. For greater accuracy, the angle can also be divided into smaller increments such as 45 degrees, 90 degrees, 135 degrees, etc. 5. Finally, mark the point where the long leg of the steel square intersects with the other side of the angle, indicating the correct position for the 191.25-degree angle. By following these instructions, a steel square can be effectively utilized to measure and mark a 191.25-degree angle. It is important to double-check measurements and take the necessary time to ensure accuracy.

- Q:Can a steel square be used for measuring inside corners?

- Certainly! The steel square is capable of measuring inside corners. Referred to as a framing square or carpenter's square, it is a versatile tool that is commonly utilized in construction and woodworking. Its design features a right angle shape, which enables precise measurement and marking of corners, including those on the inside. To measure one side of the corner, the square's long arm can be employed, while aligning the shorter arm with the adjacent side allows for determining the angle of the corner. As a result, this tool proves beneficial in various tasks, such as assessing the alignment of door frames, establishing joinery angles, and confirming the accuracy of inside corners during construction projects.

- Q:Can a steel square be used for metalworking?

- Yes, a steel square can be used for metalworking. Steel squares are commonly used in metalworking to measure and mark angles, ensure accurate cuts, and check the squareness of corners. They are versatile tools that are widely used by metalworkers for various tasks such as layout work, welding, and fabrication processes.

- Q:Can a steel square be used for checking the levelness of a countertop?

- No, a steel square cannot be used for checking the levelness of a countertop.

- Q:How do you use a steel square to find angles for scribe cuts?

- In order to find angles for scribe cuts using a steel square, a few steps must be followed. First and foremost, it is important to ensure that the steel square is clean and in good condition. This will guarantee precise measurements. Following that, position the square against the edge of the material where the scribe cut will be made, with one side of the square running parallel to the edge. Then, adjust the square's position until the other side aligns with the desired angle for the scribe cut. Once the square is properly positioned, mark a line along the edge of the square using a pencil or scribe. After marking the line, remove the square and carefully examine the marked line to confirm its straightness and accuracy. Lastly, using an appropriate cutting tool, proceed to make the scribe cut along the marked line. By utilizing a steel square in this manner, the process of finding and transferring angles for scribe cuts becomes effortless, resulting in precise and clean outcomes.

- Q:How do you use a steel square to measure and mark out crosscuts?

- To use a steel square to measure and mark out crosscuts, you would first align the long edge of the square with the edge of the material you want to cut. Then, ensure that the square is perpendicular to the edge by checking the 90-degree angle. Next, make a mark at the desired length of the crosscut along the short edge of the square. Finally, use a ruler or straight edge to connect the mark with the edge of the material, creating a straight line to guide your cut.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords