High Purity Graphite Electrode for Smelting Zinc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

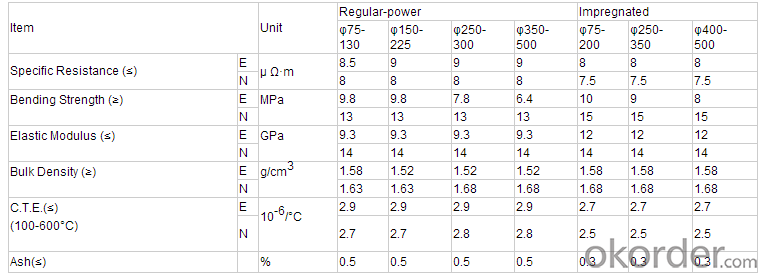

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- The oxygen will react with the graphite and the gas will dissolve.The iron has been oxidized.

- Q:Thermal expansion coefficient of graphite

- In the graphite electrode, the national standard, the volume density in more than 1.60 of both high power graphite electrode, of course because of the national standard index is low now, the volume density of normal power graphite electrode factory can reach 1.65, such as Chengde and long carbon factory.

- Q:What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q:How long is the graphite electrode machining cycle?

- When the cut depth is less than 0.2mm, the graphite will break down very little, and the surface quality of the side wall will be better.

- Q:What do carbon products include?

- Carbon products can be divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, carbon fiber, special graphite, graphite heat exchanger and so on according to the use of products. Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density.

- Q:What about graphite electrodes for steel mills?

- The graphite electrode steelmaking is to enter the electric energy through the graphite electrode to the electric arc furnace, and takes the arc between the electrode end and the furnace charge as the heat source to carry on the steel smelting. The electric arc furnace takes electric energy as heat source, and can adjust the atmosphere in the furnace. It is very beneficial to smelt the steel which contains more easily oxidized elements. Smelting a variety of alloys

- Q:Graphitized coke, graphite, broken, mixed up, how to export?

- Graphite fossil oil coke is the best smelting carburizing agent. In the steel-making industry, to produce good steel, there must be good raw materials, including good carburizing agent, and the graphitization of petroleum coke is the best carburizing agent.

- Q:What is the difference between SGL graphite electrode and graphite electrode in general?

- In fact, the graphite electrode abroad (including Japan) in several ways than we can control the fine, one is pure, another is anisotropic (resistance, thermal conductivity ah) usually do some control, in the strength of domestic now is also doing well, but when we are comparing high quality products, general domestic products it is basically a piece of the indicators are poor

- Q:Graphite electrode press device

- (1) ordinary power graphite electrode, using graphite electrode with current density lower than 17A / cm 2, is mainly used in steel-making, smelting silicon, refining yellow phosphorus and other common power electric stove(2) anti oxidation coating graphite electrode. The surface is coated with an anti oxidation protective layer of graphite electrode to form a protective layer which has both conductive and high-temperature oxidation resistance, thus reducing the electrode consumption during steelmaking

- Q:What is the application of wire cutting with graphite electrode?

- With the development of science and technology, the machine manufacturing technology has undergone profound changes. Due to the social demand for diversification of products is more intense, more varieties, small batch production increasing proportion in WEDM by traditional processing equipment has been difficult to adapt to the processing of high efficiency, high quality, diversified requirements, CNC technology should be used

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Graphite Electrode for Smelting Zinc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords