High Pure Ceramic Fiber Blanket with Heat Insualtion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Ceramic Fiber Blanket is made by continuous processing method. The fiber interweave shapely after being needled. It has excellent tensile strength. The blanket do not contains any bonding agent.

Ceramic Fiber Blanket not only can resist the chemical species, but also the hydrofluoric acid, phosphoric acid and strong base. The Fiber Blanket has excellent capability of resisting the oil. After being dried, it will repossess the thermal characteristic and the physical feature.

Ceramic Fiber Blanket Applications:

-Industrial kiln, heating device, high-temperature pipeline wall lining.

-Wall lining of chemical high-temperature conversion unit and heating equipment.

-Fireproof and heat insulation of tall buildings.

-Heat insulation of kiln door and roofs.

-Materials of high-temperature filtration.

Ceramic Fiber Blanket Advantages:

-Excellent thermal stability and shock resistance

-Strong tensile resistance

-Excellent heat insulation, fireproof and sound insulation

Main Product Features:

1. High quality

2. High working temperature.

3. Fast delivery and very competitive prices.

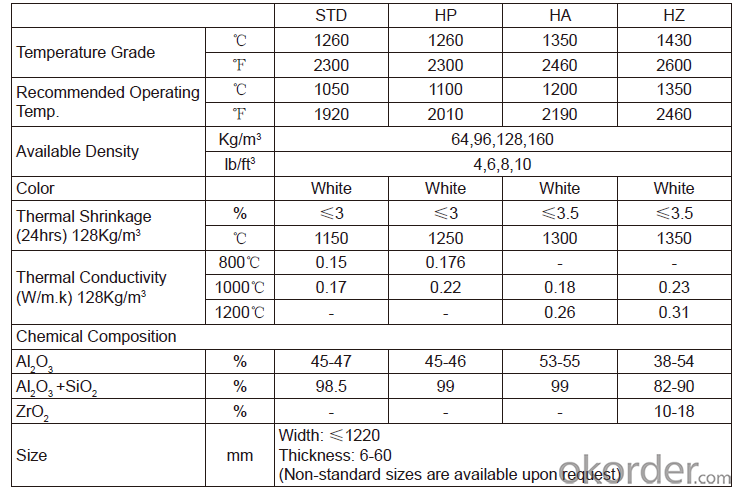

Product Specifications:

FAQ:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:i am 14 172cm tall and basically all i can do is 45mins exersize a day and eat friuts, veg and fish and chicken so how long will it takeme to lose 15-20kg

- I live in a wooded area so my food garbage just gets launched off the back porchI guess you could take your food garbage to a wooded area or vacant lotMaybe there is a local garden club that needs the compost If you have enough metal you can look up metal recycling shops and they will pay you for it The more we recycle the demand for recycled products grows.

- Q:Please tell me some low fat, low calories, high fiber foods?

- I like Nature Valley Fibre Source barsThey're 100% whole grain and have 5g of fibre, 2g protein, and 2g fat containing your omegas You can buy low-fat whole wheat bread at the supermarket, or whole grain english muffinsCereals are great - I like raisin bran, but there is also bran flakes and lots of other healthy cereals like Museli (not too sure on the spelling) Remember, vegetables and fruit have plenty of fibre in them and are a great lower calorie choice.

- Q:I am new to creating crafts for resaleI prefer fibers created in the USA due to the hassle and expense of international shippingGoogle searches bring up a lot of websites, but most source from outside the country and offer what seems to be prices that are quot;too good to be truequot;.

- Start taking more fiber in your dietHowever, you have to slowly increase your fiber intakeYou can't go from nothing to eating a box of fiber cereal a day because your body has to adapt to the fiber and create more bacteria to break down the fiber.

- Q:hair straightener, remington, SUCKS! it straightens my hair fairly decent but it leaves my hair smelling burnt and some of my hair pieces get all frizzy and like burnt or somethingi had an amazing straightener it was like some french name but i cant get that one again because the last one i had like popped and stopped workinggso, what to do you guys recommend? nothing really expensive pleasethankss (:

- That's kind of hard to do without knowing what your food preferences areHowever, here's my favorite way to fix New York strip steak, which is my current food passionMarinate the steak for several hours in Worchestershire sauce, a few tablespoons of water, and a shake or two of onion and garlic powderGrill over medium coals until the steak is to your liking(I prefer medium well.) While the steak is cooking, saute some chopped green pepper, sliced mushrooms, and slivered onions in butter or margarinePut the steak on a serving plate, pour the drained veggies over it, and top with a few crumbles of bleu cheese (if you like it.) Simple and delicious!

- Q:Please tell me what everyday foods are highest in protein and fibre?? Just 5 of each?

- I think they shouldScouts can't really tell how well batters will hit with a wooden bat, as aluminum bats obviously help the ball travel fartherThe Brewers have an advantage with their 1st round Canadian Catcher that they drafted, because they already know how he hits with a wooden batLike I said before, they really should.

- Q:Why or why not?

- Wrap it in aluminum/tin foil.

- Q:i have wavy thick hair and it frizzes easyand i was wondering what hair straightener i should useand not too expensive, im only 13and what kind of products i should use with it.thanx!!!

- okay, first off, the large majority of vaccines do not contain formaldehyde, aluminum, and aborted fetal tissue (especially this one), the vaccines that your children are given contain a weakened or dead virus so the body can learn to recognize it, thats all, only a few specialty vaccines contain the other stuff and they wouldnt be given to your child at a normal checkupwant some rationalization, thousands, if not millions, of children would be dead without vaccinesthe odds of something going wrong because of the vaccine is incredibly slim and the death rate of unvaccinated children greatly exceeds the risks of them.

- Q:How to make fake dreads using yarn or wool yarn?

- To make yarn dreadlocks, you will need at least one ball of thick wool yarn or roving, a pair of scissors, and a rubber hair elasticYou will also need access to a sink with warm running water and some shampooThe yarn for dreadlocks should be wool or another animal fiber like alpaca; synthetic fibers like acrylic and plant fibers like cotton do not feltAllow about an hour to make a thick set of yarn dreadlocks, not including drying timeDetermine how long the yarn dreadlocks should be; the easiest way to do this is to hold strip of yarn up against your head and look in the mirrorAdjust the yarn placement and length until you have the look you wantTo cut the wool to the right length, fold a long piece of yarn in half and cut it to the size of your sampleThis will yield a strip of yarn that is double the length of your sample pieceStart with about a dozen double-length strips of yarn; you can always add more if you need themUse a lark's head knot to tie one strip of wool to the elastic band, positioning the knot at the halfway pointHold the wool yarn under warm running water and add a drop of shampooHold the wood strands together and rub them back and forth through your hands to twist them togetherRub the wool yarn between your hands for about a minute; the warm water and agitation will cause the strands to stick together, forming the first yarn dreadlockRepeat for the remaining strands, then let the piece air dryMore strands can be added to make a fuller, more elaborate set of yarn dreadlocks by using the same processTo wear, gather hair into a ponytail or pigtails and secureWrap the elastic with the yarn dreadlocks around the ponytail, covering your hair as desiredDreadlocks made from yarn do not require any special care; just remove them and store until the next use.

- Q:what is count in cotton yarn?

- While tin foil is ideal for this project, it must be remembered that aluminum foil was all the rage by the time of the Roswell incident when the aliens began to infiltrate the government and to start the mind control beamsAnd similar to the success of aluminum foil balls inside your hubcaps to throw off police radar, aluminum foil has always worked very well in all post-Roswell radiation protectionThe important thing, whether aluminum or tin, is that the hat must be a exact scale duplication of the Great Pyramid of GizaThis is of the utmost importance; after all, when was the last time that you saw an alien in the Great Pyramid of Giza?! They don't dare enter in thereNow that we are specifically looking to protect us from the LHC, the most critical aspect is alignment, alignment, alignmentNo matter where you face, you need a lateral side at a perfect right angle to the LHCSo thank goodness for GPS! You can buy my step-motor interface that ties your GPS to your foil hat and always keeps a lateral side to the LHCOh, and you need my titanium-scented candles to keep away any free electrons from your spiritYou have no idea how essential that is! George Bush didn't buy any of my titanium-scented candles and look what happened to him!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Pure Ceramic Fiber Blanket with Heat Insualtion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products