High-Pressure Laminates Sheet HPL Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

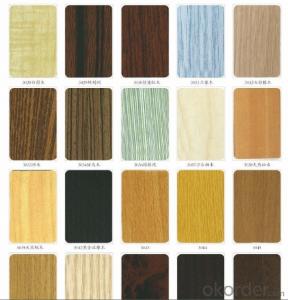

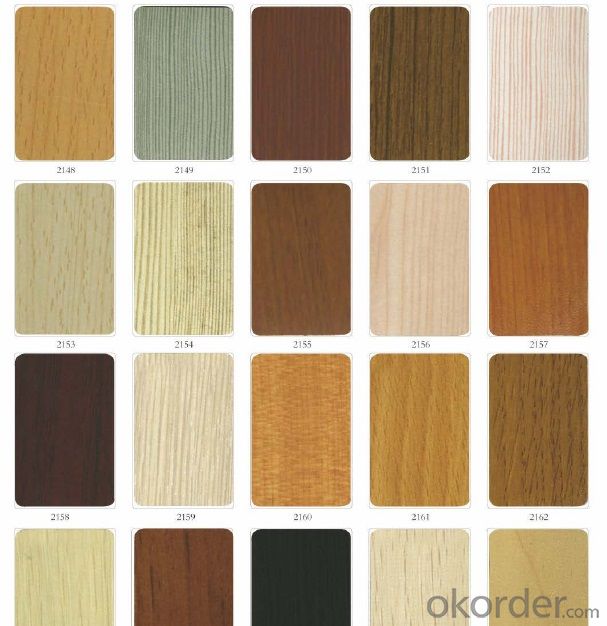

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

7. delivery time It depends on the specific order quantity

8.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:What is the thickness of the thick fireproof coating?

- Thin steel structure Fireproof coating: 2.5 hours of fire resistance, the thickness is 4.9mm 2.0 hours of fire resistance, the thickness is 3.5mm1.5 hours of fire resistance, the thickness is 1.75mm1.0 hours of fire resistance, the thickness is 1.17mm thick Coated fire retardant coating is generally between 8-45mm brushing, spraying construction should be divided to complete the thickness of each spray should be 5 ~ 10mm, must be in the previous dry or cured, and then spray again. Spray coating protection, spraying the number of times with the thickness of the coating should be based on the requirements of the construction design of the twitching of the tumbling of the pile, The first general brushing 3-5mm, after each in between 7-10mm. It should be noted that the first time after drying or curing before the second brushing. Until the thickness of the construction requirements is reached.

- Q:A1 grade external wall insulation materials which

- At present, only rock wool, glass wool, ceramic fiber, foam glass, inorganic insulation mortar, a1 grade materials generally should not contain organic materials.

- Q:Gypsum board with fire performance is it?

- Gypsum board with fire, but do not use the gypsum board wall fire, gypsum board support is mainly by two layers of paper, the paper burned after the board on the scattered, if you want to fire recommended calcium silicate board or Fiber cement pressure plate

- Q:What is Class A Fire What is Class B Fireproof?

- Jiuxin building materials "HIP ultra-thin vacuum fire insulation board" A-class fire, low thermal conductivity, CCTV 10 special report.

- Q:Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- General floor and glass curtain wall cracks are required to build layers of fire, up and down for the 1.5 galvanized steel plate, the middle folder 100 thick rock wool. The lower part of the floor can do fire, the upper 1mm galvanized sheet with a block.

- Q:Can the interior cement board be used? Is it a fireproof material?

- Would you like to ask if your cement board is in what position? Please explain it in detail? Interior decoration with cement board can be. Is a fireproof material.

- Q:Polyurethane fireproof material really effective?

- This ad must be given full marks

- Q:Extruded board fire B1, B2 grade material how to distinguish

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

- Q:If not expensive to buy one of the best, but OKorder did not find. Because I have some important documents, documents, money, worry about living somewhere a day of fire. In case, I would like to put these important objects inside the bag can be fire. Not much of a thing, a folder size of the bag is enough. What materials can be used to make one way? Can also wrap the line, but can often open, not like the tape that ridge set up the plateau dry chop suck raft by the sample sealed. Thank you. More

- 2

- Q:Decorative materials Fireproof paint three degrees What does it mean

- Fire paint three degrees, three degrees is three times (times), the general budget above the called. Different fire retardant paint in the construction of the ingot dumplings chubby off the rafters when the request is not the same {to do the budget in accordance with the actual and design}.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Laminates Sheet HPL Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords