High-Pressure Decorative Laminates for Kitchen Used

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

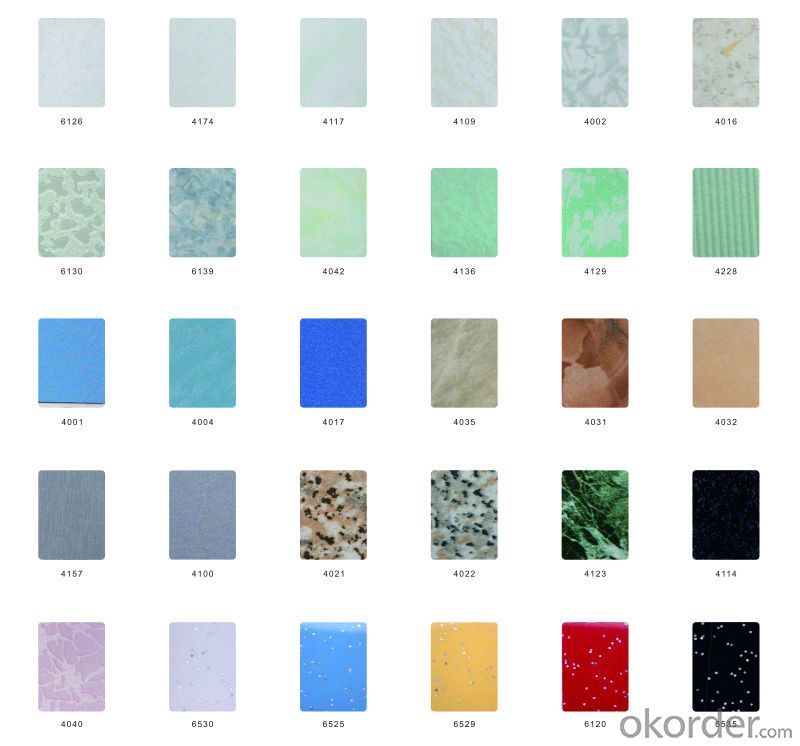

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

6 usage. 1) Can be widely used for decorative materials of interior walls, bathroom, sliding doors, ceilings, kitchens, wardrobe etc.

2) Can be used for the body of furnitures and kitchens.

3) Can be wiedly used for hotel, clubs, bars, restaurant and so on.

4) Can be widly used for box to gift, shoes,wine etc.

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:What is the thickness of the thin fire retardant paint brushing each time?

- Thin-type fire retardant coatings on the market for water-based paint, do not rule out the possibility of oil paint. Generally there are two kinds of spraying or brushing. Spraying thickness is generally between 05-1mm. According to the different characteristics of the coating to determine the construction process.

- Q:What are the building firefighting materials?

- Fire extinguisher, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm , Fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, A sense of manual alarm button, sound and light alarm, and so on

- Q:The fire resistance of building materials includes the nature of building materials

- The burning performance of a building material refers to all physical and chemical changes that occur during combustion or fire, which is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity Produce and other characteristics to measure. China's national standard GB8624-97 will be the burning of building materials into the following grades. Class A: Noncombustible Building Materials B1 Grade: Flammable Building Materials Grade B2: Flammable Building Materials B3 Grade: Flammable Buildings Lawyers Unrestricted Karma Karma Stuck But Stem Material Section 2 Combustion Performance and Fire Resistance of Building Components limit

- Q:Will the fire paint in general can buy it? Guiqiu.

- Engineering construction is of course from the manufacturers purchase friends.

- Q:What is the fire door to do? What is the price?

- Filled with pearl board, outside the paste fire board, the top layer of melamine board paste!

- Q:What is A grade fireproof material?

- A grade fireproof material refers to non-combustible material, is a kind of fireproof material. In China, building materials are divided into A, B1, B2, B3 four kinds of materials, respectively, said nonflammable, flame retardant, flammable and flammable, commonly used building fireproof material is A, B1, B2 three.

- Q:A1 grade external wall insulation materials which

- As the name suggests, A-class fire insulation material that is a fire rating of A-class fire insulation materials. Class A materials include A1: single inorganic incombustible; A2: composite organic noncombustible, that is, composite materials. Class A is non-combustible materials: WW inorganic reactive wall insulation materials, cement foam insulation board, glass beads insulation mortar, rock wool board, glass wool board, foam ceramics. Class A is a non-combustible material with low density, low thermal conductivity, high pressure capacity, convenient construction, economical and durable characteristics, widely used in hot pipes, thermal equipment and other industrial piping equipment and industrial building insulation materials and insulation Industrial and civil construction envelope insulation, insulation, sound absorption materials. Because of its good thermal stability, and more for the steel structure of the fire protection coating material.

- Q:Gypsum fire?

- Gypsum fire performance is very good, you can rest assured that use!...

- Q:Wood-plastic material fire?

- Fire rating is classified. Can not simply say that wood-plastic material fire or not. According to the composition of wood-plastic materials, which is mainly plastic and wood powder, in order to increase the fire resistance of wood-plastic, plus a certain amount of flame retardants, but the type and number of flame retardants and a direct impact on the fire for the box The performance of the valley. At present, many wood-plastic materials, the highest level of fire should be in the B1 level, the need for a stronger fire rating, then the need for special formula, many companies can not do a class A fire rating. Detailed advice ::

- Q:Fire doors with fire insulation materials which?

- Perlite fire door core; glass magnesium fire door core

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Decorative Laminates for Kitchen Used

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords