High-Pressure Laminates with Colorful Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

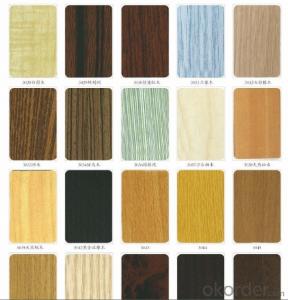

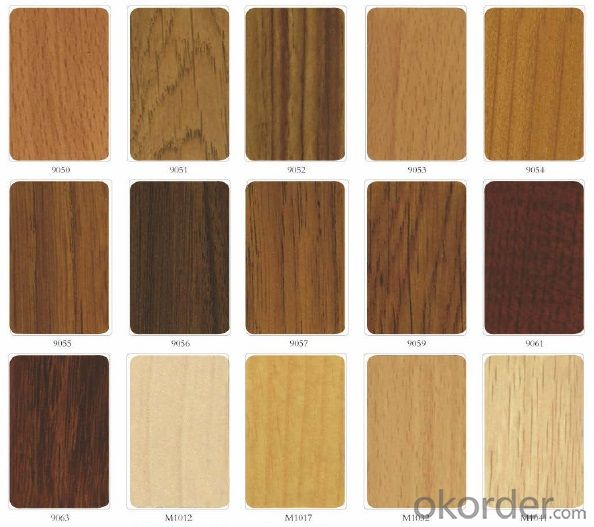

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:What are the standards for national fire-resistant materials?

- 1, the design of fire safety norms 2, the fire alarm system construction acceptance norms 3, automatic sprinkler system construction 5, building fire facilities testing procedures listed above are the national standard or ministerial standards and local norms such as:

- Q:Conventional gypsum board fire rating is several levels?

- B1 level, but in accordance with the provisions of the national standard gypsum board and light steel keel can be used together when the A-level materials, Ordinary paper gypsum board detection level for the B1 level

- Q:Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Belong to the flammable material is absolutely can not be used in the ceiling, to use the flame retardant material Caixing, fire technical specifications are required.

- Q:Insulation class fire rating non - combustible A - level and A2 - level difference

- This is the building materials and products burning performance classification is now the use of the 06 standard, the combustion level of the sub-A1, A2, B, C and other corresponding to the previous foolish pit pits Qi bogey bogey 97 standard A-level (non-combustible) B1 (flame retardant) B2 (combustible) B3 (flammable) Now both standards are used

- Q:What are the building materials, building materials, and interior decoration materials with fire resistance? Can be specific point!

- Fireproof paint! Firewall, etc., you can go to the fire security fancy check, there is a section devoted to explain the fireproof material.

- Q:Gypsum board with fire performance is it?

- Gypsum board with light, fire, heat insulation, sound insulation, convenient decoration, etc., but the general performance of the gypsum board fire less, fire gypsum board fire effect is good, generally more than 40 minutes, if accompanied by light steel Keel and fire rock wool produced by the wall of the fire time can be as high as one hour or more.

- Q:Guiqiu big god, online and other urgent! Will hydration of calcium silicate heat dehydrate to change calcium silicate?

- This is not very know how ah

- Q:Must be fireproof material!

- Can not. Polystyrene is flame retardant and non-flame retardant of the points, the flame is generally self-extinguishing. Polystyrene refers to the polymer from the styrene monomer by free radical polymerization synthesis of the polymer, the English name for the Polystyrene, Japanese name for the Poly ス チ ロ ー ル, referred to as PS. It is a colorless and transparent thermoplastic, with a glass transition temperature higher than 100 degrees Celsius, and is often used to make disposable containers that require temperatures that require boiling water, as well as disposable foam boxes.

- Q:Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire source and other parts of the pipeline through the fire, must use non-combustible insulation materials fire retardant coating, fire sealant...

- Q:Do you need to do floor fire isolation? There are those regulations for fire protection

- 6.2.9 The shaft of the elevator shaft in the building shall meet the following requirements: 1 The elevator shaft shall be set independently. No combustible gas and A, B and C liquid piping shall be laid in the well, and no cables and wires shall be laid. In addition to the installation of elevator doors, safety escape doors and ventilation holes, should not set other openings; 2 cable wells, pipe wells, flue gas, exhaust, garbage Road and other vertical shaft, should be set independently The The fire resistance of the borehole wall shall not be less than 1.00h and the inspection door on the wall of the shaft shall be of Class C fireproof door. 3 The cable wells and pipe wells in the building shall use non-combustible materials not less than the fire resistance of the floor at each floor Or fire blocking material plugging. The construction of the cable wells, pipe wells and rooms, walkways and other connected pores should be used to block the fire blocking material; 4 buildings within the garbage should be set by the external walls of the garbage should be directly open to the outdoor, Garbage bucket should be made of non-combustible materials, and should be able to shut down; outdoor billboards should not be blocked the construction of the window, should not affect the external fire rescue operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Laminates with Colorful Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords