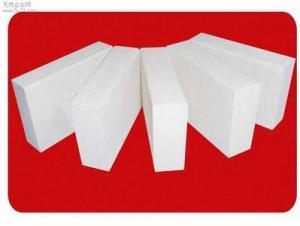

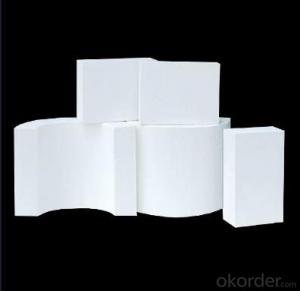

Calcium Silicate Boards Model 04 with Good Quality for Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Calcium Silicate Board:

A calcium silicate board is one of the new-type building materials recommended by the Ministry of Construction. It is a light, high-strength, fire-resistant and heat-proof material composed of scientific proportions of siliceous and calcareous materials, adulterated with appropriate amount of reinforcing materials, which are processed through pulping, molding, autoclave curing, drying and sandpaper polishing.

Main component:

Wood fiber, cement and so on. The nominal size is 1220*2440/1200*2400, with the maxium length 3.66m.

Physical performance of Calcium Silicate Board:

1.100% non-asbestos

2. Density: 1000-1200 KG/m3

3. Coefficient of thermal expansion: 0.24W/MK(JC/T54)

4. Bending strength: Over 13Mpa(GB/T7019-1997)

5. Linear expansion rate: 0.1%

6. Water absorption rate: Less 0.19%(GB/T7019-1997)

7. Water penetration rate: 0%

8. Water content: 10%

9. Incombustibility, A grade; Waterproof

10. Radioactivity: Standard(GB6566-2000)

Main Characteristics of Calcium Silicate Board:

1. Light weight

2. The wall is solid and firm inside, and resistant to impact pressure

3. Painting, tiling and nailing is possible in the new system

4. Noise reduction can be up to 46 dB

5. Good efficiency

6. Fireproof, damp proof

7. Easy to install 8. Stable dimensions

Specifications of Calcium Silicate Board:

1) Thickness: 4 - 20mm

2) Normal Size: 1220*2440/1200*2400, with the maxium length 3.66m.

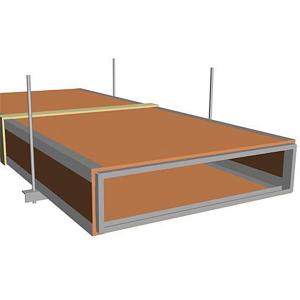

Usage of Calcium Silicate Board:

The magnesium board is widely adoptable to partition and suspending ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation, sound insulation wall places with dampness, mobile partition, special class fire prevevention, sandwiched plate in fireproof- gate and packaging of equipment cases.

Packaging & Delivery of Calcium Silicate Board:

Pieces with palletes or pieces loosely in the container.

- Q:Calcium silicate board ceiling need to do the bottom plate

- Do not need, calcium silicate board structure is relatively hard, the plate can cut a big one, the direct ceiling can be, do not need to do the bottom of the splint.

- Q:What is the popularity of the living room recently?

- Depends on your chandelier is what kind of shape. Flat ceiling, then use the light steel keel calcium silicate board cover modeling smallpox words using light steel keel +9% plywood + calcium silicate board cover Calcium silicate board cost and gypsum board almost but the strength of hard, fan do not crack ~ ~

- Q:Silicon calcium board ceiling specifications which? Silicon calcium board ceiling brand which?

- Specifications are many, you can go to the online mall to see, there are many brands on the mall

- Q:Calcium silicate board irregularly split, some sink, what reason? How to deal with it? More

- Is it 600 * 600? Light steel keel hanging, or wire? Sinking is usually caused by a long deformation of the keel. If it is the basic wire hanging will appear this situation. Because the wire for a long time will slowly straighten with the weight, so it will sink. Cracking is normal. Generally the life of this plate for a few years. The wet place will change for two or three years. This plate is highly absorbent. There was water soon bad. It is recommended to change the time to choose aluminum, but the price will be much higher.

- Q:Fiber cement pressure plate and calcium silicate board What is the difference, what is the use

- Differences: 1, their raw materials are different. Calcium silicate board is the use of siliceous, calcium material and a certain proportion of fiber materials as the main material, by the pulp, molding, autoclaved curing from. Fiber cement is based on fiber and cement as the main raw material for the production of cement cement plate. 2, fiber cement pressure plate bending strength is V level, calcium carbonate board strength is IV level. Fiber cement pressure plate than calcium silicate board strength. Uses: Calcium silicate board and fiber cement board are common architectural decoration materials on the market, used in the construction of ceiling ceilings and partitions, home decoration, furniture liner, billboard liner, ship cabin, Board, network floor and tunnel and other indoor works of the wall; commercial buildings of commercial buildings, entertainment and bathing places, shopping malls, hotels; industrial buildings of the factories, warehouses; residential buildings of the new residential, renovation renovation; public places hospitals, theaters , Station, subway and so on. The main use is the wall, ceiling, floor, furniture, road insulation, sound absorption barrier, ship compartment and duct and other industrial panels and suction walls, sound absorption ceiling, pouring walls, composite wall panels and other fields.

- Q:Is the calcium silicate board wall a lightweight barrier?

- Calcium silicate board is a fireproof waterproof board, belonging to the light partition series. Before the construction of the calcium silicate board wall decoration works, the quality, structure and size deviation of the ceiling skeleton and the partition wall skeleton, water supply and drainage, and the gas pipe, Inspection and acceptance. So that the need for hidden acceptance.

- Q:8mm thick calcium silicate board (CalciumSilicateBoard) how much money a square meter!

- 8 mm chrysotile calcium silicate board 26 yuan a, excluding tax and shipping

- Q:Calcium silicate board scraping off easily how to deal with

- You use the glue is not good, or match the wrong, looking for suppliers to ask.

- Q:What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Calcium silicate board is used for decoration, interior decoration. You said that this material should not be calcium silicate board. Haha.

- Q:Calcium silicate board and aluminum plastic plate which is good

- Calcium silicate board is not waterproof, and the material is almost the same as the gypsum. The surface of the aluminum-plastic plate is aluminum and the back is plastic. In general, the material properties are better than the calcium silicate board. , Construction, calcium silicate board easy to construction. The higher the better the number of aluminum-plastic plate, the more expensive, that is used in the outdoor are not too big problem, is easy to pale.

1. Manufacturer Overview |

|

|---|---|

| Location | Foshan, China |

| Year Established | 1996 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; Australia; Africa; Southeast Asia;China |

| Company Certifications | ISO 9001:2008; CE EN12467:2012; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan; Guangzhou; Shenzhen |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 5 people |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 100,000.00SQM |

| No. of Production Lines | 4 (plan add 2pcs product lines in 2014) |

| Contract Manufacturing | OEM Service Offered; Own Brand; |

| Product Price Range | 6mm Higt Density: USD2.72/SQM, Average price6mm Mid Density: USD1.85/SQM,Averange price |

Send your message to us

Calcium Silicate Boards Model 04 with Good Quality for Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products