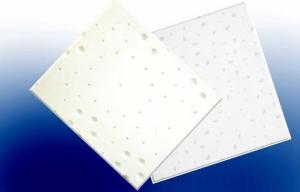

Asbestos-free and High strength Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

100% Non-asbestos Calcium silicates board

1)Easy to Install.

2)Standard Quality

3)Economic

4)CE & ISO Approved.

100% Non-asbestos Calcium silicates board

Calcium silicates board

Calcium silicates board

Calcium silicates board

| Convenient Construction | The Calcium Silicate Board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The Calcium Silicate board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 6.5,7,7.5,8,9,9.5,10,12,12.5, |

| Surface treatment | Non |

| Production capacity | 10,000m2/day |

- Q:Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- If it is calcium carbonate plate can not be replaced, calcium silicate board itself tide!

- Q:Calcium silicate board does not paint it

- Look at how specific you use, do not brush paint is also possible

- Q:Decoration

- 1. Thermal insulation with calcium silicate board called microporous calcium silicate, is a white, hard new insulation material, with a light weight, high strength, small thermal conductivity, high temperature, corrosion resistance, can cut, Features. Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually more than 30mm, the density of 200-1000kg / m3.2. Decorative calcium silicate board, the thickness of 4-20mm, length and width to 1220 * 2440mm mainly. Calcium silicate board (English: calciumsilicate) as a new green building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and industrial applications in the ceiling ceiling and Wall panels, home furnishings, furniture linings, billboard linings, shipboard trays, warehouses, floor panels, and tunnels. Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q:Calcium silicate board model specifications

- Is a white, hard new insulation material, with a light weight, high strength, thermal conductivity of filial piety high temperature, corrosion resistance. Can cut, can saw and so on. Thickness according to design needs

- Q:What is the difference between calcium silicate board and cement pressure plate?

- Is not the same thing, the cement board is cement as the main condensate material through the formation of natural conservation, high strength, but the deformation coefficient. Calcium silicate board is made of siliceous material and calcareous materials such as lime and quartz sand through high temperature and high pressure to form terrestrial monolithic inorganic crystals. Although the strength of cement board, but also generally more than 11 MPa, to meet the requirements. Deformation coefficient is small, fire rating for the highest "non-flammable". It is far more than the resistance of the cement fiberboard to the deformation resistance of the calcium silicate board. Because the calcium carbonate board cement content is not high, while the latter are basically cement. Cement is easy to deform. Please add points.

- Q:Ceiling, then the paper gypsum board, calcium silicate board, silicon calcium board three What is the difference, can recommend the next? The

- Ceiling gypsum board is better!

- Q:Do you need to have a fire rating? In the Chinese fire product information network above only to find calcium silicate board wall of the relevant information! More

- Need, calcium silicate board refractory grade non-combustible A1 level. If a fire occurs, the plate will not burn, it will not produce toxic smoke.

- Q:Export of calcium silicate board or gypsum board, which one shipping cheap?

- The problem is high. How is the freight? First answer the following questions 1. Air / sea / land / courier, etc. which you choose 2. From where to where 3. The volume of goods Fu tiger brother Xi Xi Ding Ding Ding busy gross weight 4. Start time to think These three questions and then look for freight forwarding companies, different ways of transport billing in different ways, such as shipping: General you can charter / bulk cargo container is also very thin 40 Pu 40 ultra high 20 small cabinet special cabinet (frozen What kind of) air there are two kinds of billing: give you 2 price XX yuan / kg XX yuan / party according to your weight and volume of goods are calculated to calculate which is your preferred. Different airlines have different Of the starting standards, and some less than one party by a formula, and some side by side by two formulas, so the three questions to find out, looking for a freight forwarding. So that you can have a more accurate freight

- Q:Calcium silicate board can do outdoor waterproof wall directly?

- Can not, not all of the calcium silicate board can do so, must start from the raw materials there, because the direct use of outdoor, because the density is relatively high, so the plate itself is very low moisture content, but the calcium silicate board physical The nature of the surface of the plate will determine how much the surface will be the problem of water droplets, water droplets will gather dust, water will be completely volatile after the emergence of very difficult to see the water.

- Q:It is better to use a glassy magnesium board and a calcium silicate board

- Calcium silicate board. Humid conditions, glass magnesium board components will change the crystal form, the release of magnesium chloride in the formation of frost on the board commonly known as halogen, while losing strength. It is disgraceful to advertise on the upstairs, but the platform is really great, and I am in use, and my whole family is in use. The The

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Asbestos-free and High strength Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords