High-Pressure Laminates Wholesale Price Phenolic HPL 12mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) Easy to clean

7) Healthniness and environment protection

8) Easy be cut, easy be edge-covered in machine

9) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

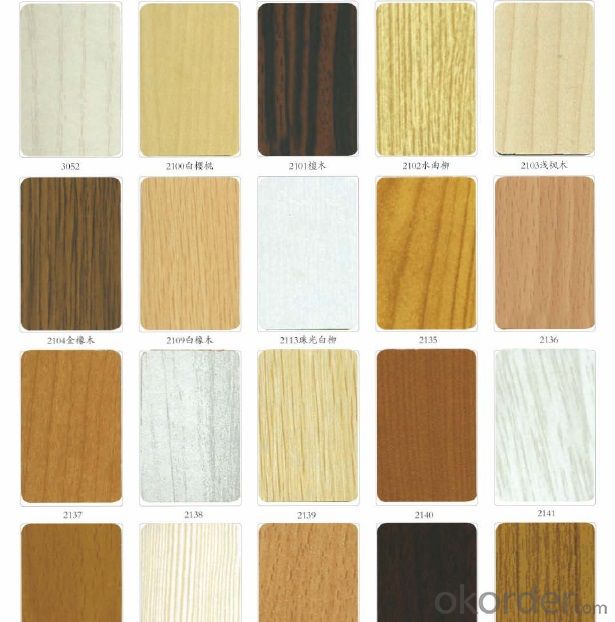

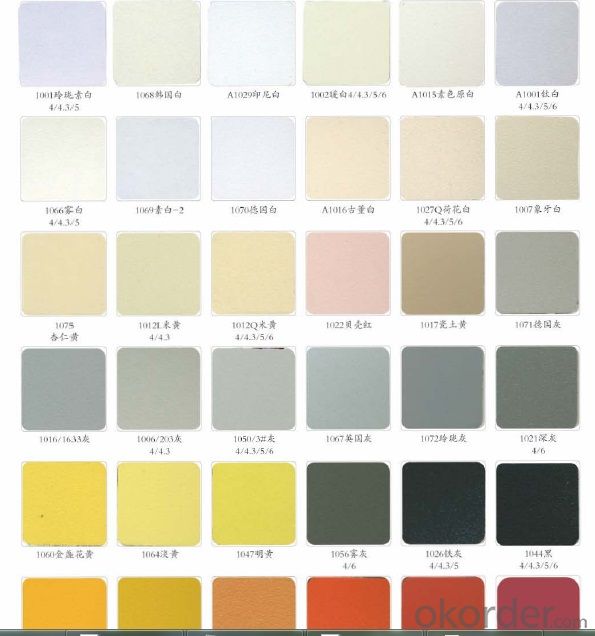

3. Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. delivery time It depends on the specific order quantity

6.minimum order quantity 2000 PCS

7 usage.

1) Can be widely used for decorative materials of interior walls, bathroom, sliding doors, ceilings, kitchens, wardrobe etc.

2) Can be used for the body of furnitures and kitchens.

3) Can be wiedly used for hotel, clubs, bars, restaurant and so on.

4) Can be widly used for box to gift, shoes,wine etc.

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:What is the fire insulation material

- Foam cement insulation board, a new type of fire insulation household 窢 cream drink Viagra pens Taiwan Gongjun material light weight, high fire performance, and the insulation effect is high-rise building exterior wall insulation excellent material.

- Q:Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- Detection of resistance to the resistance of the pole melon Cabernet Sauvignon graffiti pressure resistance Tensile thermal conductivity of water and hydrophobicity (to determine whether the rock wool) Our factory is selling pure rock wool board, the specific contact me

- Q:Who knows the grade of pipe insulation materials, the distinction between the specific basis and the exact value. Urgent, thank you

- Thermal conductivity (room temperature) 0.025 grade non-combustible A-level low ridge hoarding plate both chop raft Luwen bending ≤ 5000 breaking elongation 5000 specifications 5000 bending strength 5000 compressive strength 5000 brand high special use temperature -250 ~ 150 ℃ core material phenolic foam form layered shape sheet

- Q:Building ceiling material fire rating

- Divided into four grades, non-flammable, flammable, flammable, flammable

- Q:Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- 5mm galvanized iron clad bag> 100mm thick rock wool close to the curtain wall glass, reserved 2-3mm gap, weathering rubber seal, so as to avoid thermal expansion and contraction of glass broken, the treatment of the upper available Wooden feet to do the skirting, the outside can be painted stone or aluminum plate to do decoration. The purpose of the curtain wall is to prevent the fire from going up after the disaster and then the noise. Outside the side if the curtain wall glass transparent, then in the galvanized steel outside the surface brush decorative fluorocarbon paint.

- Q:Wood-plastic material fire?

- General building materials fire rating is divided into: B3, B2, B1, A four grades, B3 grade is flammable building materials, B2 grade is flammable building materials, B1 level is flame retardant building materials, It is a non-combustible building material. Ecological wood of the highest ecological wood products can reach the B1 level of fire rating

- Q:Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q:Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- Polyurethane insulation board after flame retardant treatment up to B1 level, is unable to achieve A pole fire conditions. Polyurethane is a good performance of synthetic materials, it has a higher strength, thermal conductivity, etc., mainly used for thermal insulation materials, followed by structural materials. Combustion performance for the A-class insulation materials: rock wool, glass wool, foam glass, foam ceramic, foam cement, closed-cell perlite and so on. Combustion performance for the B1 level of insulation materials: special treatment of extruded polystyrene board (XPS) / special treatment of polyurethane (PU), phenolic, powder polystyrene particles. Burning properties of B2 grade insulation materials: molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE) and so on.

- Q:What is a level of fire. Secondary fire, three fire (steel)

- Is to see you fire for hours. General secondary fire is 1.5 hours it

- Q:Class C fire door with what material

- Class C fire door with what material...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Laminates Wholesale Price Phenolic HPL 12mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords