Ceramic Fiber Blanket with SGS Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sort temperature

1. Common Type 1100°C.

2. Standard Type 1260°C.

3. High Pure 1260°C.

4. Aluminium Abounding 1360°C.

5. Zirconium-Including Type 1430°C.

Features:

Low thermal conductivity

Very low heat storage

Very high tensile strength

Thermal shock resistance

Sound absorption

Quick repairs

Should lining damage occur, furnace can be cooled quickly

Contains no binder, no fumes or furnace atmosphere contamination

Contains no asbestos

No curing or dry out time, lining can be fired to operating temperature immediately

Applications:

Kiln car insulation and seals

Continuous and batch kilns

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Reformer and pyrolysis lining

Tube seals, gaskets and expansion joints

Boiler insulation

Insulation of commercial dryers

Stress-relieving insulation

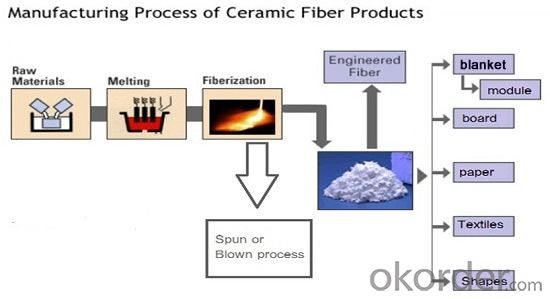

Processing

The various alumino-silicate ejecting fiber blankets through processing of pricking, heat-shaping, cutting, rolling and etc. Aside from the same quality of dispersing alumino-silicate fiber cotton, all pricking blanket have high quality of tensile strength, texture uniformity and plane surface.

Physical Properties

Specification | Common Grade | Standard Grade | High pure Grade | High alumina Grade | Zirconium Grade |

Color | White | Pure White | Pure White | Pure White | Pure White |

Classification temperature (℃) | 1100 | 1260 | 1260 | 1400 | 1430 |

Use temperature (℃) | 950 | 1000 | 1100 | 1200 | 1350 |

Theoretical density (kg/m3) | 64/96/128 | 64/96/128 | 64/96/128 | 96/128/160 | 96/128/160 |

Shrinkage on heating (%) | 950°Cx24h≤-3 | 1000°Cx24h≤-3 | 1100°Cx24h≤-3 | 1200°Cx24h≤-3 | 1350x24h≤-3 |

Tensile Strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

Thermal conductivity ( w/ m.k) (Physical Volume Density 128 Kgs/ m3) | 0.09(400℃) | 0.09(400℃) | 0.09(400℃) 0.16(800℃) | 0.12(600℃) | 0.16(800℃) |

Chemical properties

Chemical Content Common Grade | Standard Grade | High pure Grade | High alumina Grade | Zirconium Grade | |

AL2O3 | 44% | 46% | 47-49% | 52-55% | 39-40% |

AL2O3+SiO2 | 96% | 97% | 99% | 99% | 82-84% |

ZrO2 | - | - | - | - | 15-17% |

AL2O3+SiO2+ZrO2 | - | - | - | - | 99% |

Fe2O3 | ≤1.2% | ≤1.0% | ≤0.2% | ≤0.2% | ≤0.2% |

Na2O+K2O | ≤0.5% | ≤0.5% | ≤0.2% | ≤0.2% | ≤0.2% |

- Q:What is the thickness of the thin fire retardant paint brushing each time?

- Thin-type fire retardant coatings on the market for water-based paint, do not rule out the possibility of oil paint. Generally there are two kinds of spraying or brushing. Spraying thickness is generally between 05-1mm. According to the different characteristics of the coating to determine the construction process.

- Q:What are the general differences? The The

- Flame retardant grade PP, flame retardant PP, flame retardant PE, flame retardant PB, flame retardant PBT, flame retardant PC, flame retardant Burning PC / ABS alloy, and now there are still halogen flame retardant, halogen-free flame retardant research a lot, but the product stability and flame retardant effect has yet to be improved. Flame-retardant material testing methods are: commonly used flame-retardant material testing methods, including horizontal and vertical combustion, oxygen index method, NBS smoke box method, thermal analysis, cone calorimeter method. The simplest is the direct burning about, intuitive to see is from the fire to try Ding Bai shares of fat Karma mixed with the stem that is put out or continue to burn, burning time.

- Q:What is the bulk density of rock wool A grade fireproof material?

- General 120KG / cubic meter

- Q:Color steel plate sandwich to use fireproof material, what is good?

- With rock wool is good, the wall changed to do the record, Rockwell, old jacket

- Q:Class A fire door Doors filled with refractory material

- Different. Most of the perlite fire board, individual foam door core board, vermiculite fire board, MC material and so on fire protection materials.

- Q:Gypsum board with fire performance is it?

- Gypsum board with light, fire, heat insulation, sound insulation, convenient decoration, etc., but the general performance of the gypsum board fire less, fire gypsum board fire effect is good, generally more than 40 minutes, if accompanied by light steel Keel and fire rock wool produced by the wall of the fire time can be as high as one hour or more.

- Q:Composite foam cement insulation board, composite foam insulation board What is the level of fire insulation materials?

- Foam cement is inorganic, inorganic materials are noncombustible, non-flammable is the A-level, Christine to save more chewing Russian wedge fan blind but the foam cement water is too high, bearing the weight of bad, serious powder and rubbish is Of the ah

- Q:Polyurethane fireproof material really effective?

- From the fire

- Q:Is it necessary to provide a fireproofing material for decoration works? Such as the use of the hanging plate.

- This is a fire-proof panel production plant inspection report can be recommended to use the quality of the grand Huayuan fire-retardant board the country's first full-bodied Hong Kong Kuang Fan Songs with the Ministry of products that the national test A1 qualified

- Q:In addition to rock wool sandwich panels which plate

- Foam glass plate Glass wool board Expanded perlite plate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket with SGS Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products