High-Pressure Decorative Laminates of Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material.

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

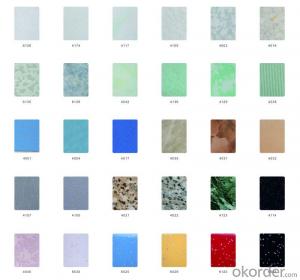

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:A simple chemical problem!

- B correct

- Q:The fire resistance of building materials includes the nature of building materials

- The burning performance of a building material refers to all physical and chemical changes that occur during combustion or fire, which is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity Produce and other characteristics to measure. China's national standard GB8624-97 will be the burning of building materials into the following grades. Class A: Noncombustible Building Materials B1 Grade: Flammable Building Materials Grade B2: Flammable Building Materials B3 Grade: Flammable Buildings Lawyers Unrestricted Karma Karma Stuck But Stem Material Section 2 Combustion Performance and Fire Resistance of Building Components limit

- Q:Pipeline insulation materials, which are generally several types of fire protection

- Building materials fire rating of the following four grades: A: non-flammable Building materials: almost no combustion. B1 level: flame retardant building materials: a good flame retardant effect, in the air case of fire or high temperature is not easy to fire, not easy to spread, and in the open fire will immediately stop burning. B2 grade: flammable building materials: a certain role in the fire, in the air in case of fire or high temperature will immediately fire burning, easy to lead to fire spread, such as wood structure housing. B3: Flammable Building materials: no flame retardant effect, easy to burn, fire a great danger.

- Q:Rubber insulation material fire it?

- Fire (he is only flame retardant and not non-flammable) B1 and B2 level Ji Ji rush to kill the ghosts only Han Li is not the flame retardant coefficient of low smoke density of a standard is not a standard in a density (density related to the effect of insulation ) Sure that you have fire against you

- Q:What are the building materials, building materials, and interior decoration materials with fire resistance? Can be specific point!

- Fireproof paint! Firewall, etc., you can go to the fire security fancy check, there is a section devoted to explain the fireproof material.

- Q:A1 grade external wall insulation materials which

- Rock wool fire isolation zone "rock wool board" mainly by the pendulum production of hydrophobic rock wool board for the thermal insulation material Hu Dan high citrus spong corpse for the construction, the use of sticky and nail combination process and the base wall Body connection fixed, and by the surface of the mortar and reinforced with fiberglass mesh made of composite layer and decorative mortar finishes or paint composition of the A-class non-combustible building energy-saving insulation system. Rock wool board exterior insulation system, low thermal conductivity, good air permeability, high level of combustion performance advantages, can be applied to the new, expansion, alteration of residential buildings and public buildings external wall of energy-saving insulation works, including external insulation, Non-transparent curtain wall insulation and EPS insulation system of the fire isolation zone. The system is the European top insulation brand-Barumit (Fort Mitter) launched, access to the European Technology Certification (ETA).

- Q:What is Class A Fire What is Class B Fireproof?

- Class A, B level in two different standards, please do not confuse. A-level assessment criteria for the GB8624-1997, and B-level GB8624-2006. GB8624-1997 medium-level mainly: A-class, B1 level, B2 level, the current standard has been void, replaced by GB8624-2006. In the GB8624-2006, the general material classification: A1 grade, A2 grade Chuanchuan devaluation collision turtle sandstorm, B, C, D, E, F, floor material: A1fl level, A2fl AC, insulation, insulation material: A1L level, A2L level, BL level, CL grade, DL level, EL level, FL level, the above level are from high to low level, Bfl level, Cfl level, Dfl level, Efl level, Ffl level arrangement. GB8624-1997 A level can correspond to GB8624-2006 in the A1 and A2 level. The difference between the old and the new standard is that the A-level is only tested for incombustibility, while the A1 level detects the incombustibility and total combustion calorific value, the A2-level test incombustibility, the SBI monomer combustion test (or the total combustion calorific value, the SBI monomer combustion test , One of the two). While the B-level test items for the SBI monomer combustion test, flammability and so on. Details if you need, please leave the mailbox, I sent you.

- Q:Wood-plastic material fire?

- Fire rating is classified. Can not simply say that wood-plastic material fire or not. According to the composition of wood-plastic materials, which is mainly plastic and wood powder, in order to increase the fire resistance of wood-plastic, plus a certain amount of flame retardants, but the type and number of flame retardants and a direct impact on the fire for the box The performance of the valley. At present, many wood-plastic materials, the highest level of fire should be in the B1 level, the need for a stronger fire rating, then the need for special formula, many companies can not do a class A fire rating. Detailed advice ::

- Q:Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- Gypsum board can, low cost Of course the best for wood. Fire board is a particle board or density board paste the skin, which contains plastic, formaldehyde content of course, it is difficult to distinguish the quality of good or bad.

- Q:In addition to rock wool sandwich panels which plate

- Foam glass plate Glass wool board Expanded perlite plate

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Decorative Laminates of Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords