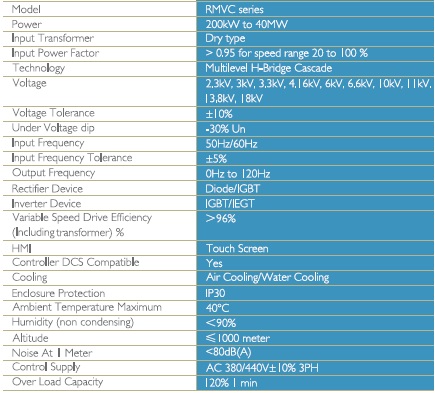

High Medium Voltage Drive 6KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q:Can the HP laptop's power adapter be universal?

- If the power adapter socket is the same as the output voltage can be common. But there are a few places to note, HP notebook power adapter output voltage there are many, the most common 19V and 18.5V, but even if the output voltage is the same, the output current may be different, that is, the output power is not the same , If your notebook needs a larger input power, then you have to use the match can be, the lower power may not make the battery normal use, and even harmful to the battery.

- Q:Can the inverter stop intermittently during operation? If so, how to connect and set up

- Look at your inverter manual, because the inverter is not a simple wiring can run, first of all have to know that a few are external terminals (inverter input terminals),

- Q:Is the laptop power adapter AC and DC?

- Notebook power adapter is not AC and DC. Power adapter is a small portable electronic equipment and electrical and electronic power supply conversion equipment, generally by the shell, power transformers and rectifier circuit, the working power for the exchange (China AC standard AC 220V), according to its output Types can be divided into AC (AC) output type and DC (DC) output type. General notebook power adapter are DC output, is the exchange of DC conversion equipment.

- Q:What is the difference when using inverter frequency conversion ordinary motor and variable frequency inverter motor

- So that mainly depends on your application and the frequency of work in the number.

- Q:What is the difference between the electronic governor and the frequency converter on the motor speed regulation?

- Electronic governor is for single-phase motor, by changing the access winding resistance and capacitance to adjust the motor speed, the speed of the power supply power for the output does not change, so this speed is not an energy Type of speed control methods, such as home for the use of fans and the like. Inverter speed is the original direct input three-phase asynchronous motor power first access to the inverter, in the inverter through the PWM and other electronic converter technology to rectify the frequency AC, inverter, become a frequency controllable AC In the input to the motor, in the motor running through the V / F control, output torque control, vector control and other control methods to adjust the frequency, change the loop current, to achieve energy-saving operation, especially in the light load energy efficiency is obvious, An energy-saving products that have been widely promoted and applied

- Q:Do not the laptop directly connected to the power adapter?

- 4, but you can use the external 14 ~ 20V battery, connected to the matching power plug for the notebook power supply, the effect and the use of the same power adapter.

- Q:How to choose the inverter

- Look at the motor seat size is 7.5kw it, this model of the inverter manufacturers a lot of production, and are built-in brake unit, so in the function which are the same It is important that the inverter life, stability, price comprehensive consideration Mitsubishi, Panasonic, LG, Emerson, Yaskawa, Siemens and so on

- Q:Speed of 3000 r / min three-phase motor how to change its speed

- Voltage regulator, variable pole speed, the best inverter speed. The

- Q:Master Hello a machine requires 500 speed matching 6-pole motor frequency converter transferred to about 28HZ

- If the machine needs the same speed, constant 500r / min This can be directly with the motor, remove the inverter, but also save costs, while the motor at 50Hz, the maximum power point of rated power. Output torque is the most stable point. The pulley diameter becomes smaller and the reduction ratio increases, and the torque required by the motor becomes smaller, which is advantageous for the motor. 960/500 = 1.92, that is to say the motor pulley compared to the original tune less 1.92 times

- Q:Three motors, if coupled with the governor speed, is it necessary to add the inverter?

- First, the frequency control: the use of frequency converter to change the frequency of the motor stator power supply, thus changing its synchronous speed control method for all motors, which is the most advanced, the most widely used speed control method.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Medium Voltage Drive 6KV 1000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords