High Hardness Steel Grinding Ball Used for Mine & Cement Plant & Power Station etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Hardness Steel Grinding Ball Used for Mine & Cement Plant & Power Station etc

1. Description of Steel Grinding Ball Used for Mine & Cement Plant & Power Station etc

Size:from 15mm to 150mm(0.75''-6'')

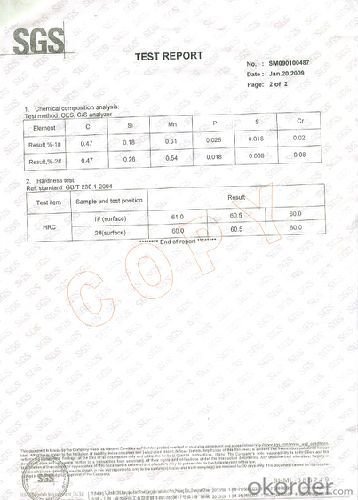

Surface Hardness: 55-67HRC, Volume Hardness: 50-63HRC

Endurance Test >20000

Impact Test>12AK.J/CM2

Application :Mining ,Cement plant, ,Power station,and other grinding industries

Certification:SGS/TUV/BV/COTECNA/ISO9001:2008

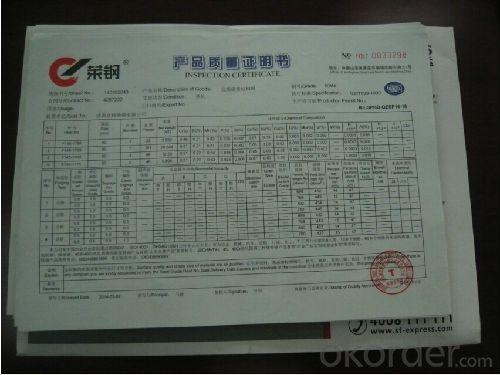

2. Chemical Composition of Steel Grinding Ball Used for Mine & Cement Plant & Power Station etc

3. Production Procedure

Testing of the raw material—Smelting—Test during smalting—Adjust chenical compostion—Moulding—Test alter smlting — Pass/Abandonment — Grinding — Surface Test — Quenching — Tempering—HardnessTesting—Packed and storage—Testing the finished products — In Stock

4. Packing

In Container bags, each one load 1M.T.

IN Drumes, Each one load 700-900KGS

5. Some Photos for Steel Grinding Ball:

- Q:What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q:What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q:Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q:My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q:For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to different casting process and parts materials, each has relevant standards, can be found online;

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

- Q:Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q:Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting.

- Q:Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High Hardness Steel Grinding Ball Used for Mine & Cement Plant & Power Station etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords