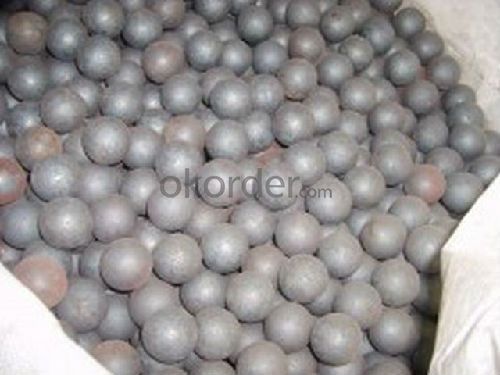

High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our grinding ball are widely used for powder preparation and extra-fine deep processing in sectors, such as cement building materials, metal mining, coal paste thermal power plants, chemical engineering, ceramic coating, light industrial paper making and magnetic materials. The cast grinding ball's hardness is high; wearing cost is low; the toughness is very good. So the breakage is few. The surface hardness of ball will be raised further in using the course, and the wear resistance would gather hard to raise mill machine production capacity and raise cement's ratio surface area and reclaim ratio of the extractive mine.

Specification of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø20 | 0.0322 | 31056 |

2 | Ø25 | 0.063 | 15873 |

3 | Ø30 | 0.11 | 9091 |

4 | Ø40 | 0.257 | 3891 |

5 | Ø50 | 0.50 | 2000 |

6 | Ø60 | 0.867 | 1153 |

7 | Ø70 | 1.37 | 729 |

8 | Ø80 | 2.05 | 487 |

9 | Ø90 | 2.90 | 345 |

10 | Ø100 | 4.00 | 250 |

11 | Ø110 | 5.30 | 188 |

12 | Ø120 | 6.80 | 147 |

13 | Ø125 | 7.75 | 129 |

14 | Ø130 | 8.74 | 114 |

The Product Description of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | 8000 | P+C |

Medium Chromium | ≥50 | 8000 | P+C |

High Chromium | ≥56 | 8000 | M+C |

Chemical Composition of High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

Model | Chemical Composition | |||||

C | Si | Mn | Cr | P | S | |

Low Chromium | 2.3-3.4 | ≤1.5 | 0.5-1.5 | 1.0-2.0 | ≤0.1 | ≤0.1 |

Medium Chromium | 2.2-2.8 | 0.5-1.0 | 0.5-0.8 | 10.0-12.0 | ≤0.1 | ≤0.1 |

High Chromium | 2.4-3.2 | 0.5-0.8 | 0.5-0.8 | 16.0-18.0 | ≤0.1 | ≤0.1 |

- Q:Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q:Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- Service performance: heat conductivity, friction reduction, shock absorption, heat resistance and corrosion resistanceTo compare these properties, it depends on the specific material, structure, and use of the parts. Otherwise, there is no comparisonS

- Q:What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q:What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

- Q:Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- This is difficult to say, the key is to see the specific parts and components, the final mechanical performance requirements.For example, gray cast iron, usually graphite annealing, to heat treatment annealing, surface quenching and so on, ductile iron can be a variety of annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical treatment and so on, in a word, heat treatment of steel can usually, nodular cast iron can do. Malleable cast iron and vermicular cast iron are often subjected to graphitization annealing and stress relieving annealing, while wear-resistant cast irons often undergo quenching + low temperature tempering, and so on.Welding is the case, such as bearing steel welding must be quenched + low temperature tempering, machine spindle welding (repair welding) must be quenched and tempered treatment, and so on. Of course, if it is a general weld, there is no need for heat treatment or, at most, stress relieving annealing.

- Q:In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q:Cause of choking of casting parts

- The reason is not in the coated sand, see coating gas evolution, the best use of zircon powder coating (low gas evolution), there is a mold according to a vent needle, this depends on your way is flat or vertical pouring pouring pouring, if vertical pouring, venting pin on the die, and the big piece how could the plane, pouring water flat, a breath, a taboo ah!

- Q:When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q:What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

1. Manufacturer Overview |

|

|---|---|

| Location | Anshan City, Liaoning Province,China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Domestic Market; South America; Eastern Asia; South Asia; Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port;Dalian Port;Tianjin Port;Yingkou Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b)Factory Information | |

| Factory Size: | 24,400 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | grinding ball,grinding media,casting ball,casting grinding ball |

| Product Price Range | Average |

Send your message to us

High Hardness Forged and Casting Grinding Mill Steel Ball For Ball Mill

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords